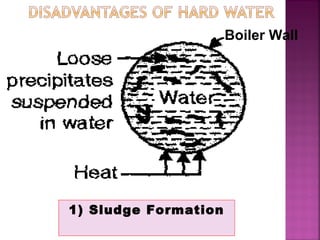

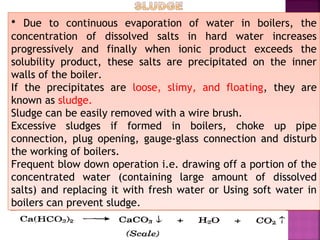

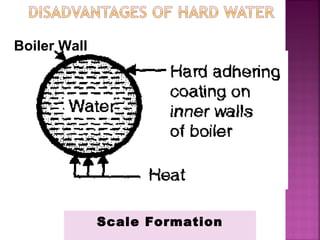

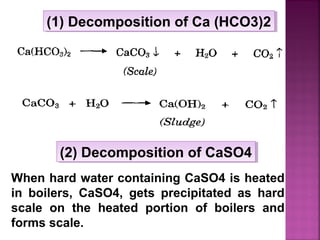

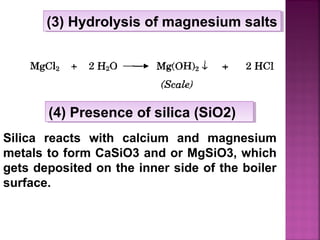

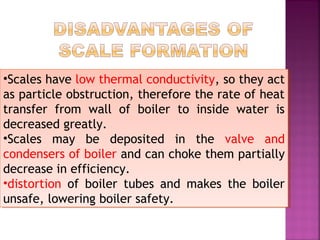

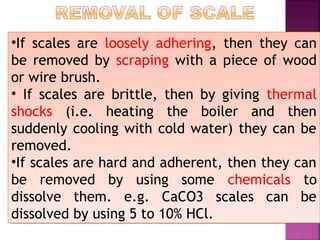

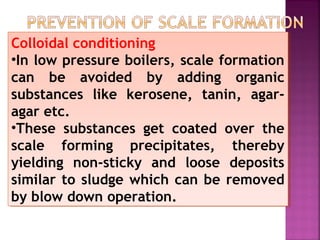

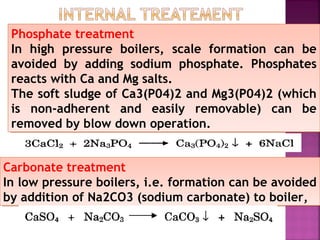

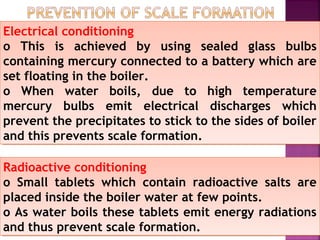

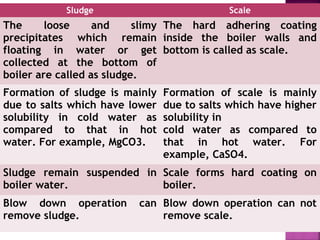

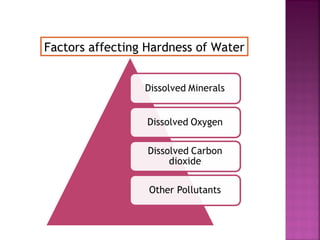

Hard water contains dissolved calcium and magnesium ions that can cause scale buildup and reduce soap efficiency. In boilers, scale forms when calcium and magnesium carbonates and sulfates precipitate out of solution as water is heated. This scale buildup reduces heat transfer efficiency and can damage boiler components over time. Several methods can be used to prevent or remove scale, including frequent blowdowns, adding antiscalants like phosphates, and chemical or mechanical scale removal treatments. Proper treatment of hard water is important for industrial processes and equipment that use water like boilers, cooling systems, and pipes.

![Treatment with sodium aluminate (NaAlO2)

When boiler water is treated with NaAIO2 in

solution, it gets hydrolysed to yield NaOH and

Al(OH)3

Treatment with sodium aluminate (NaAlO2)

When boiler water is treated with NaAIO2 in

solution, it gets hydrolysed to yield NaOH and

Al(OH)3

Calgon conditioning

Sodium hexametaphosphate Na2[Na4(PO3)6] is added

to boiler water. It prevents the scale formation by

forming soluble complex compound.

Calgon conditioning

Sodium hexametaphosphate Na2[Na4(PO3)6] is added

to boiler water. It prevents the scale formation by

forming soluble complex compound.

(Gelatinous precipitate](https://image.slidesharecdn.com/waternew-160407165301/85/Water-35-320.jpg)

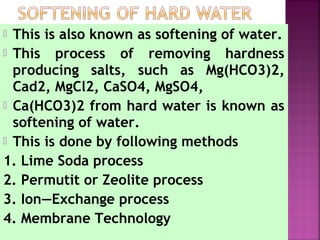

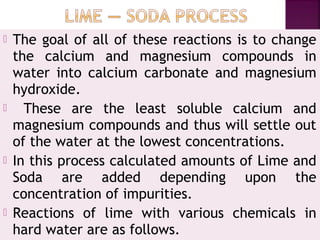

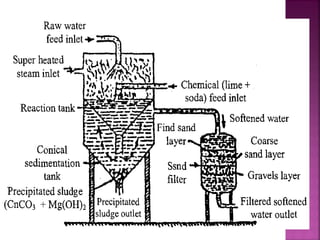

![ Principle - To convert all the soluble hardness

causing constituents into insoluble precipitates

by appropriate chemical treatments and then

removing them.

In this process calculated amounts of Lime

[Ca(OH)2] and Soda (Na2CO3) are added

depending upon the concentration of

impurities.

Reactions of lime with various chemicals in

hard water are as follows:](https://image.slidesharecdn.com/waternew-160407165301/85/Water-87-320.jpg)

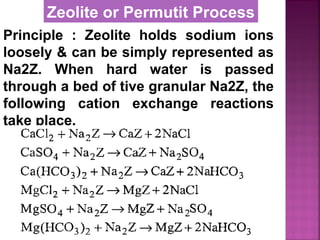

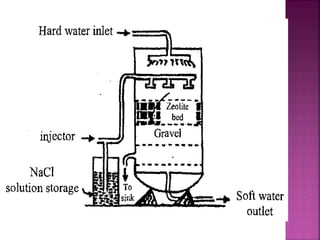

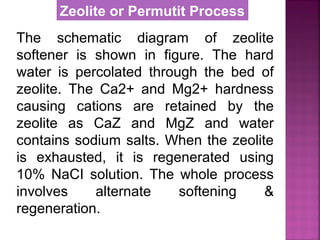

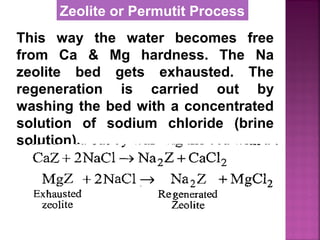

![Permutit is the technical name given

to Sodium Zeolite [Na2Z]

Na2O ∙Al2O3 . xSiO2 . yH2O

where x = 2 to 10, y = 2 to 6

It is also called hydrated sodium

alumino silicates.

It is represented as Na2Z

where Z is zeolite.

Zeolite or Permutit Process](https://image.slidesharecdn.com/waternew-160407165301/85/Water-106-320.jpg)

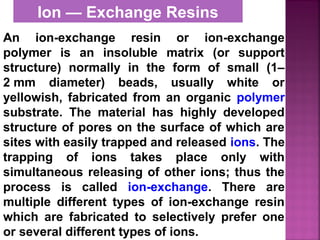

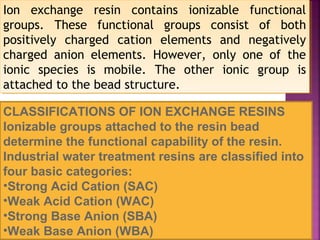

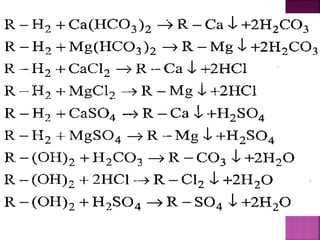

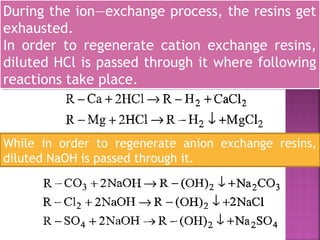

![Cation exchange resins are resins which are capable

of exchanging H+

ions, with other cations.

They contain functional groups like — SO3H, —COOH,

—H etc. They are represented as R—H2.

Commercial cation exchanger is AMBERLITE IR — 120

Anion exchange resins are resins which are capable

of exchanging OH ions, with other anions.

They contain functional groups like — NH2 or —NH as

an integral part of the resin matrix.

When they are treated with dilute NaOH solution,

they act as an anion exchange resins and are

represented as R — (OH)2.

A commercial anion exchange is AMBERLITE [R400]

Cation exchange resins are resins which are capable

of exchanging H+

ions, with other cations.

They contain functional groups like — SO3H, —COOH,

—H etc. They are represented as R—H2.

Commercial cation exchanger is AMBERLITE IR — 120

Anion exchange resins are resins which are capable

of exchanging OH ions, with other anions.

They contain functional groups like — NH2 or —NH as

an integral part of the resin matrix.

When they are treated with dilute NaOH solution,

they act as an anion exchange resins and are

represented as R — (OH)2.

A commercial anion exchange is AMBERLITE [R400]](https://image.slidesharecdn.com/waternew-160407165301/85/Water-117-320.jpg)

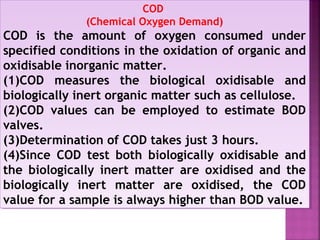

![Determination of COD

1.A known volume of sample is refluxed

with a known excess of standard

potassium dichromate (K2Cr2O7) and dil

H2S04 in presence of a little Ag2SO4

catalyst for 1½ hours.

2.The unreacted K2Cr2O7 is then titrated

against standard Mohr’s salt solution.

[FeSO4 (NH4)2 S046HO2].

3.The O2 equivalent of K2Cr2O7

consumed is taken as a measure of COD.

Determination of COD

1.A known volume of sample is refluxed

with a known excess of standard

potassium dichromate (K2Cr2O7) and dil

H2S04 in presence of a little Ag2SO4

catalyst for 1½ hours.

2.The unreacted K2Cr2O7 is then titrated

against standard Mohr’s salt solution.

[FeSO4 (NH4)2 S046HO2].

3.The O2 equivalent of K2Cr2O7

consumed is taken as a measure of COD.](https://image.slidesharecdn.com/waternew-160407165301/85/Water-175-320.jpg)