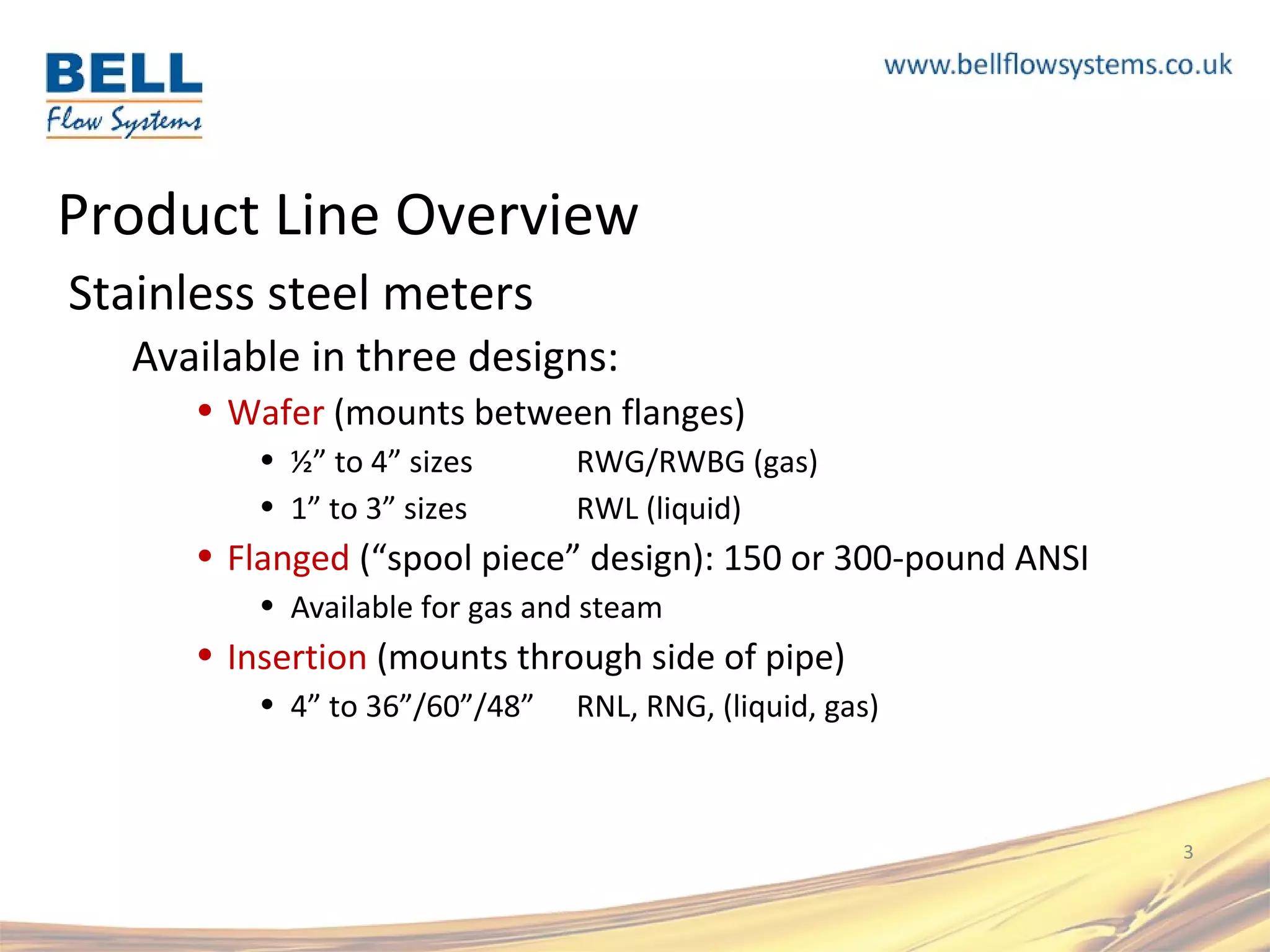

The document provides an overview of Badger Meter's vortex flow meters, detailing their product lines which include stainless steel and thermoplastic meters for liquids and gases. It highlights the unique ultrasonic and vortex-shedding technologies employed, along with advantages such as high sensitivity and low pressure drop. Specific product specifications, applications, and features are also outlined, catering primarily to industrial gas measurement and other sectors such as semiconductors and pharmaceuticals.