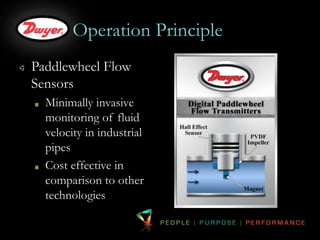

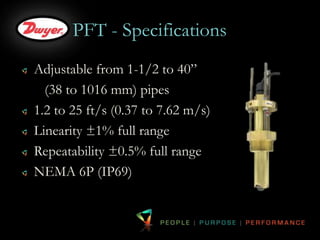

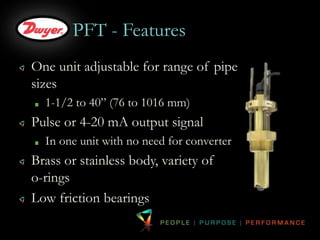

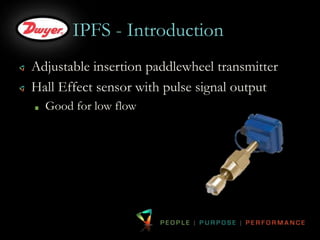

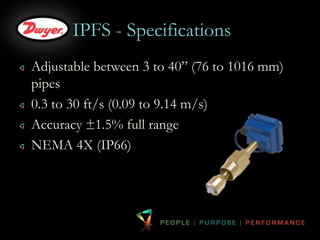

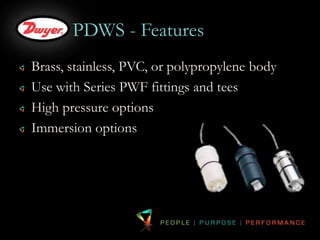

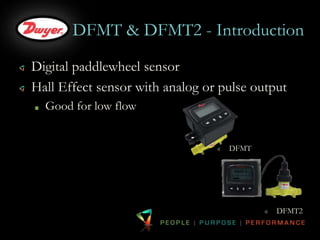

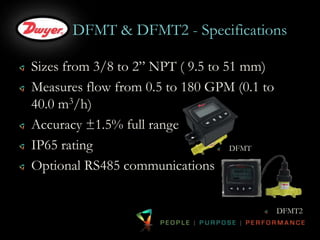

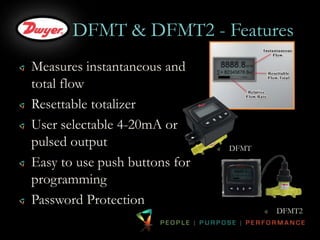

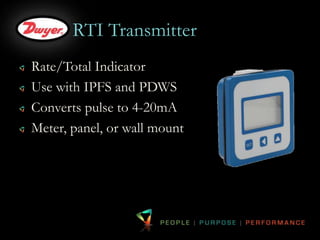

This document discusses Dwyer Instruments' paddlewheel flow sensors and transmitters. It provides an overview of their product lines including the PFT, IPFS, PDWS, DFMT/DFMT2, as well as accessories like fittings and transmitters. Specifications, features, and applications are described for each product. The materials are intended as a resource for Dwyer customers and employees and may not be reproduced without permission.