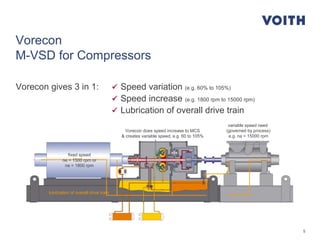

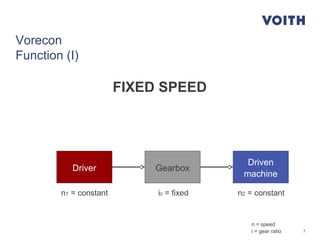

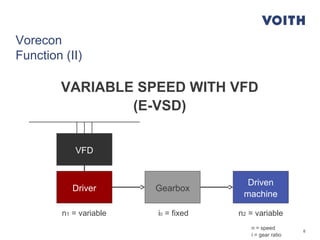

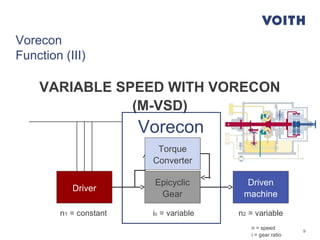

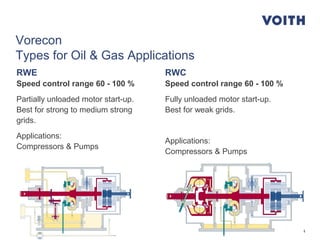

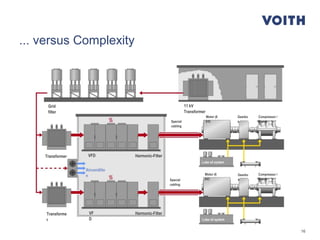

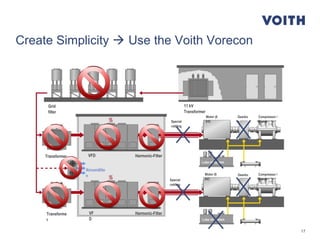

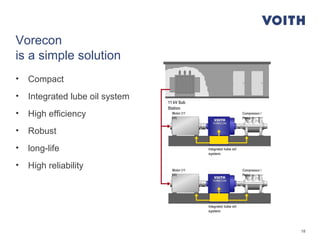

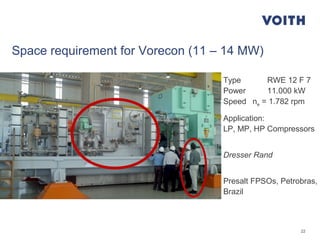

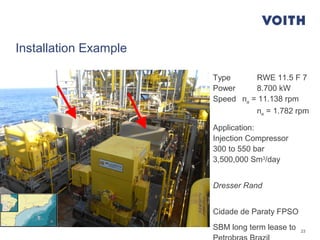

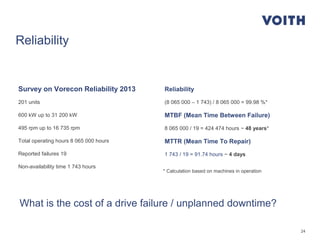

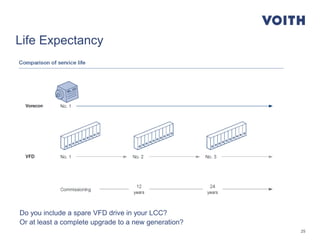

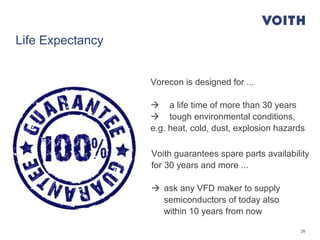

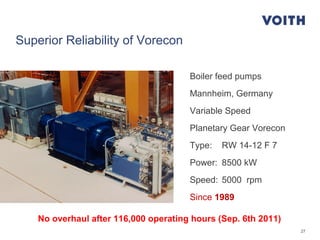

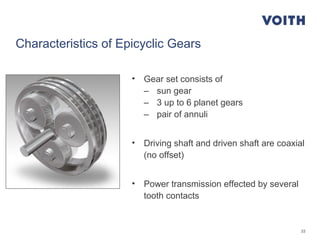

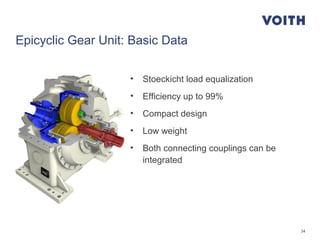

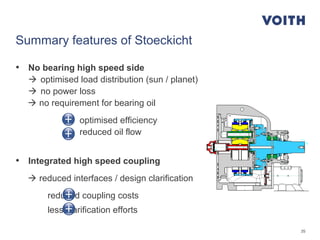

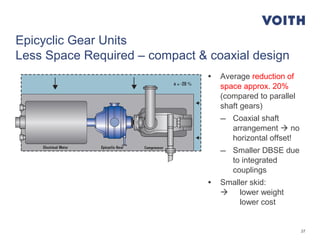

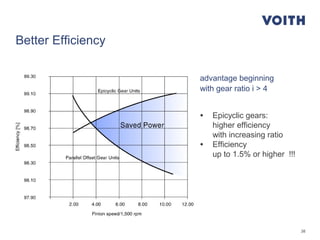

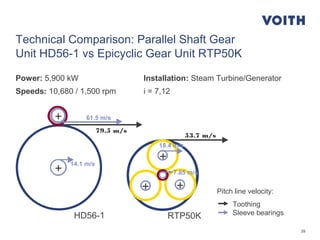

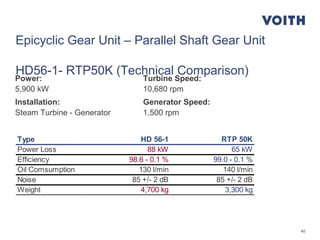

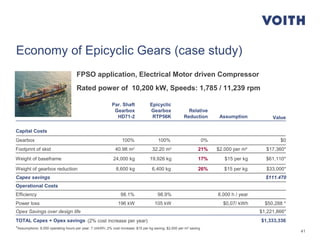

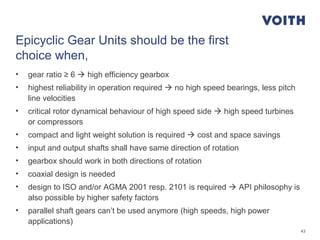

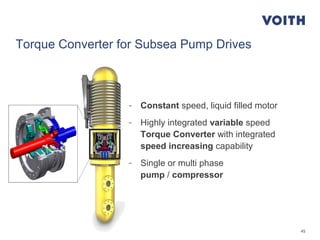

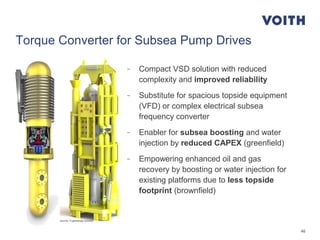

This document discusses variable speed drive solutions for offshore applications, including Voith's Vorecon solution. It provides details on Vorecon, including its applications in compressors, advantages like simplicity and reliability compared to traditional variable frequency drives, installation examples, and reliability statistics. The document also summarizes Epicyclic gear units and hydrodynamic variable speed drives for subsea applications.