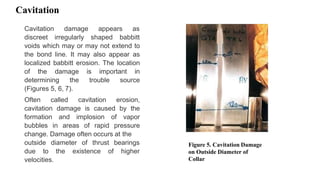

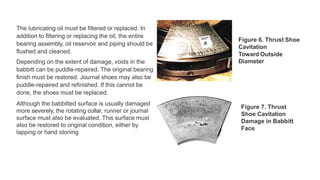

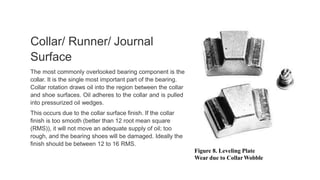

This document discusses journal bearing layout and failure identification. It begins by introducing journal bearings and the types of failures that can occur, including pitting, fatigue, erosion, cavitation, corrosion, and issues with the collar/runner/journal surface. It then provides details on each type of failure, describing the appearance and root causes. For each failure type, it recommends rectification actions such as filtering the oil, cleaning components, restoring surfaces, and addressing the underlying operational issues that led to the failure.

![INTRODUCTION

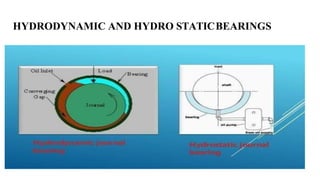

In journal bearing sliding action is along the circumference of circle

or an arc of circle and carrying radial loads. [1]](https://image.slidesharecdn.com/jbfailure-200627062044/85/Journal-Bearing-layout-and-Failure-Analysis-3-320.jpg)

![TYPES OF JOURNALBEARINGS

• According to angle of contact of journal bearings [2]](https://image.slidesharecdn.com/jbfailure-200627062044/85/Journal-Bearing-layout-and-Failure-Analysis-4-320.jpg)

![CONTINUE …..

According to thickness of lubricating layer [3]](https://image.slidesharecdn.com/jbfailure-200627062044/85/Journal-Bearing-layout-and-Failure-Analysis-5-320.jpg)