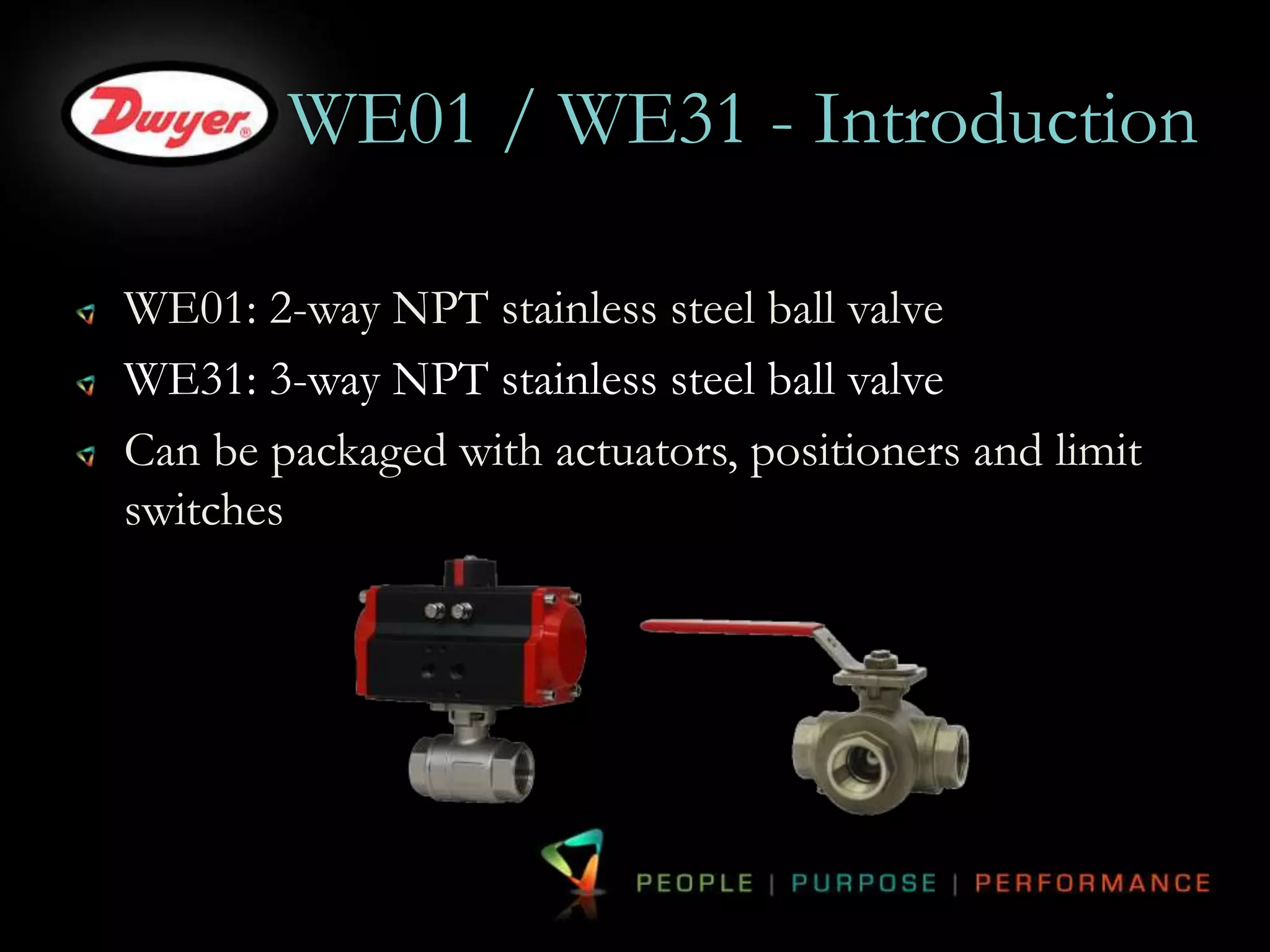

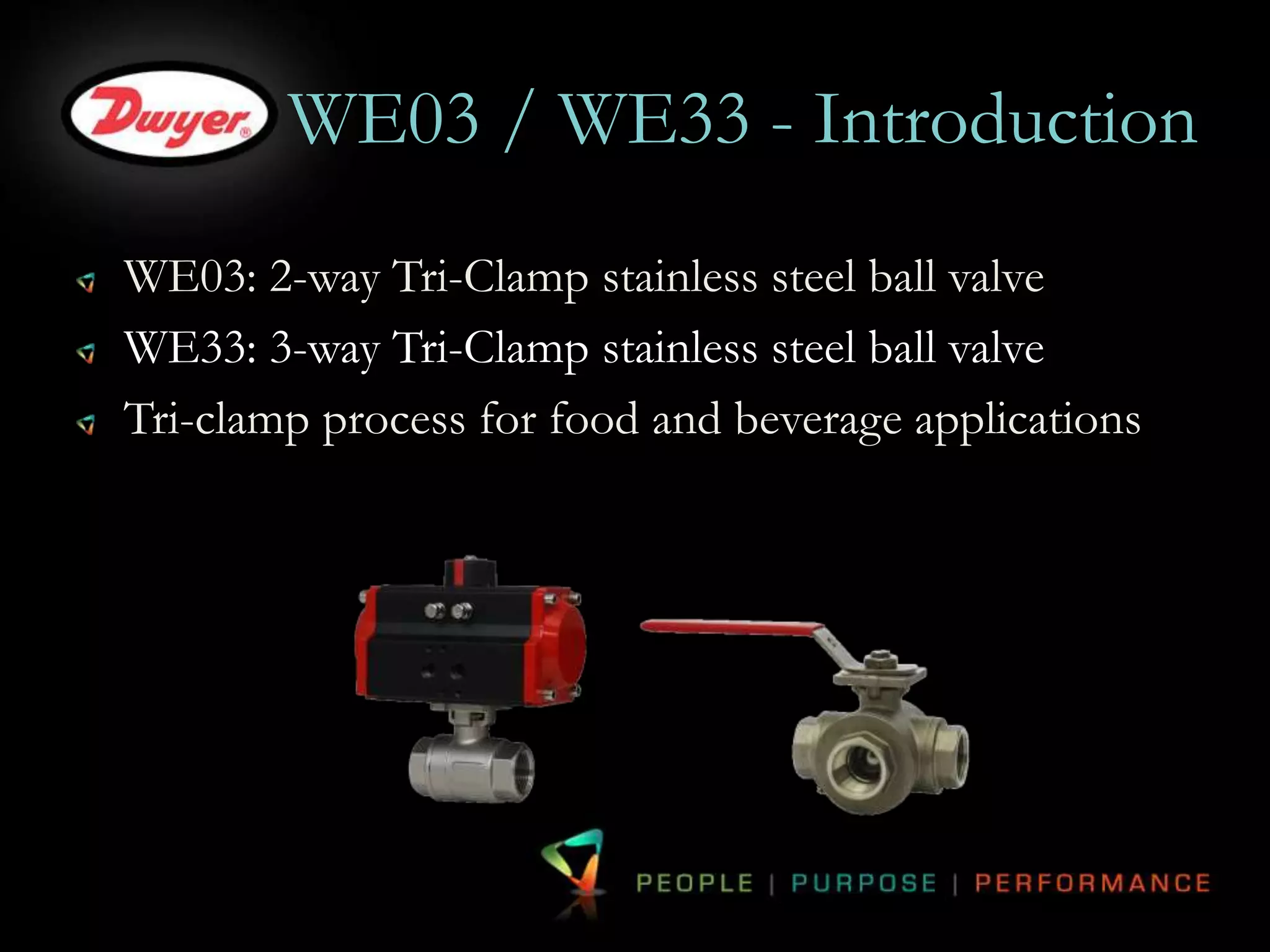

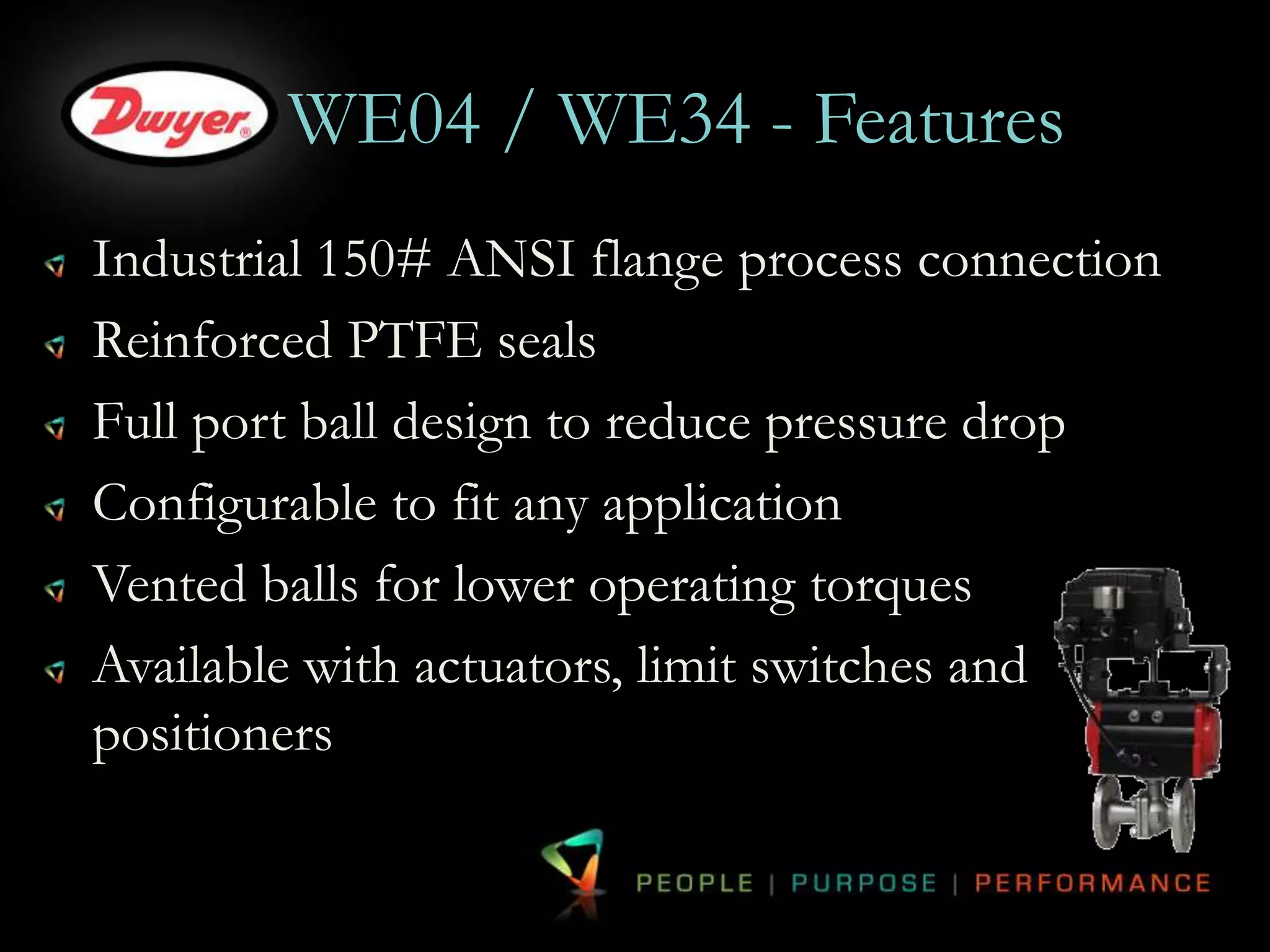

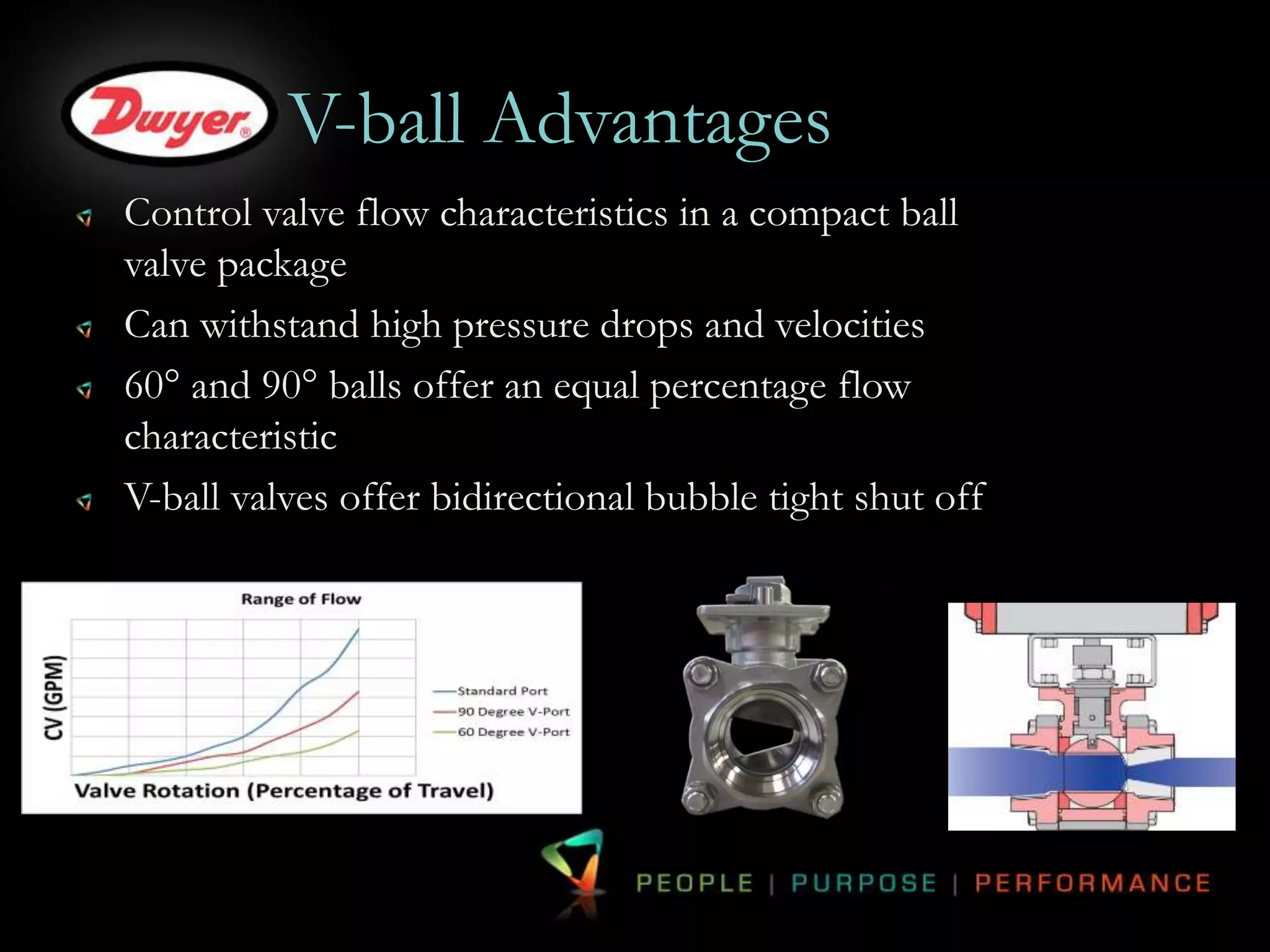

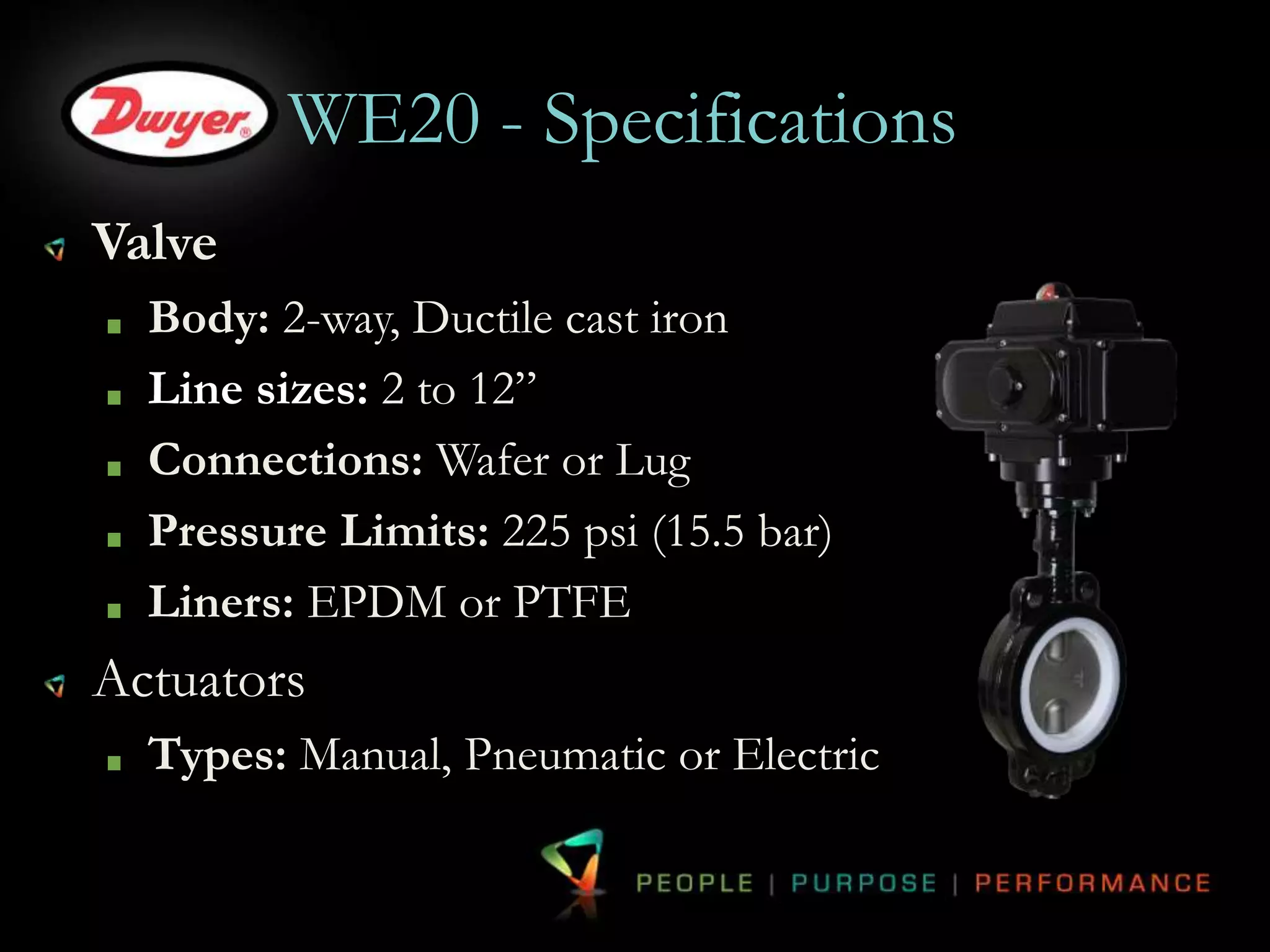

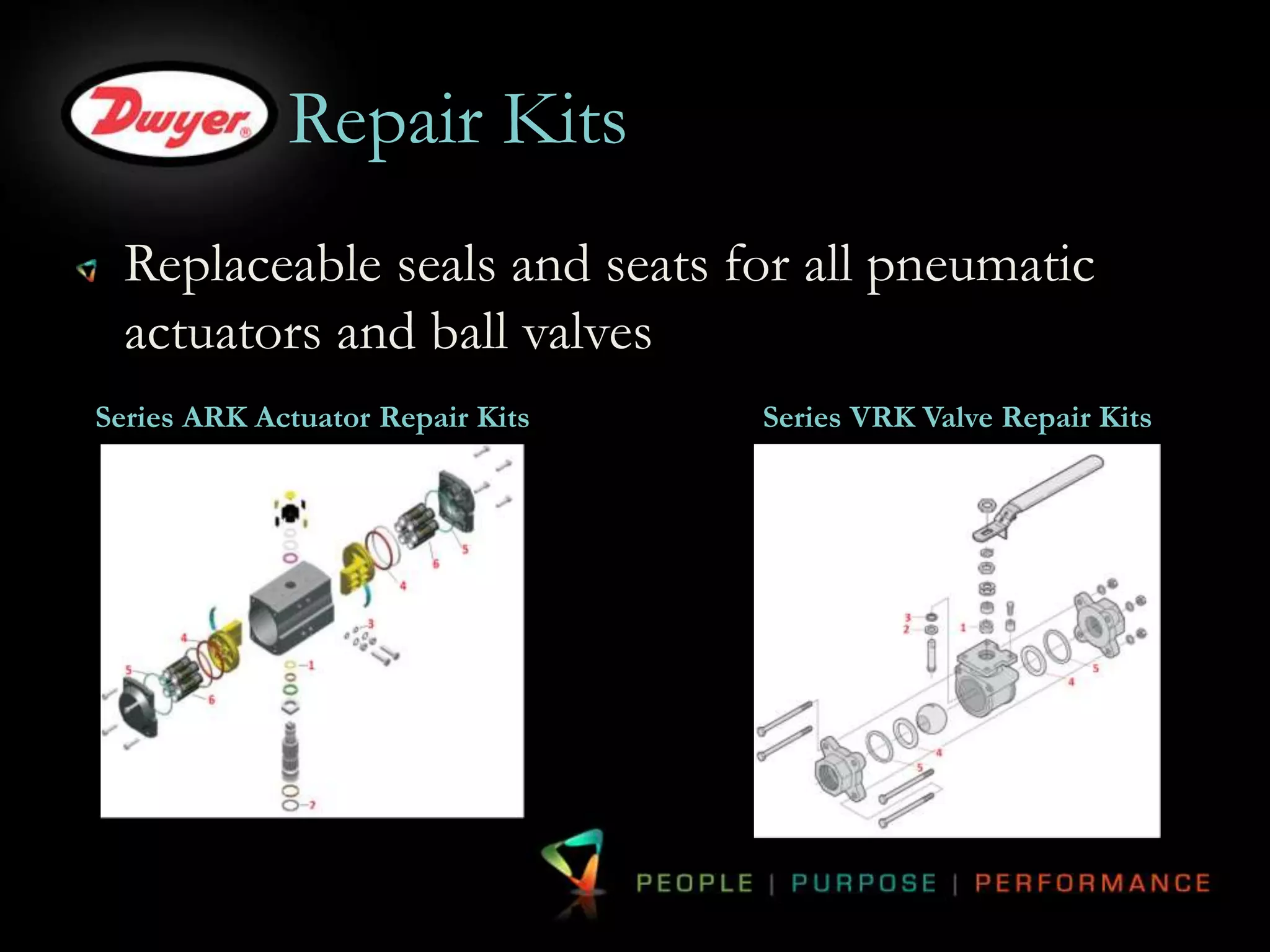

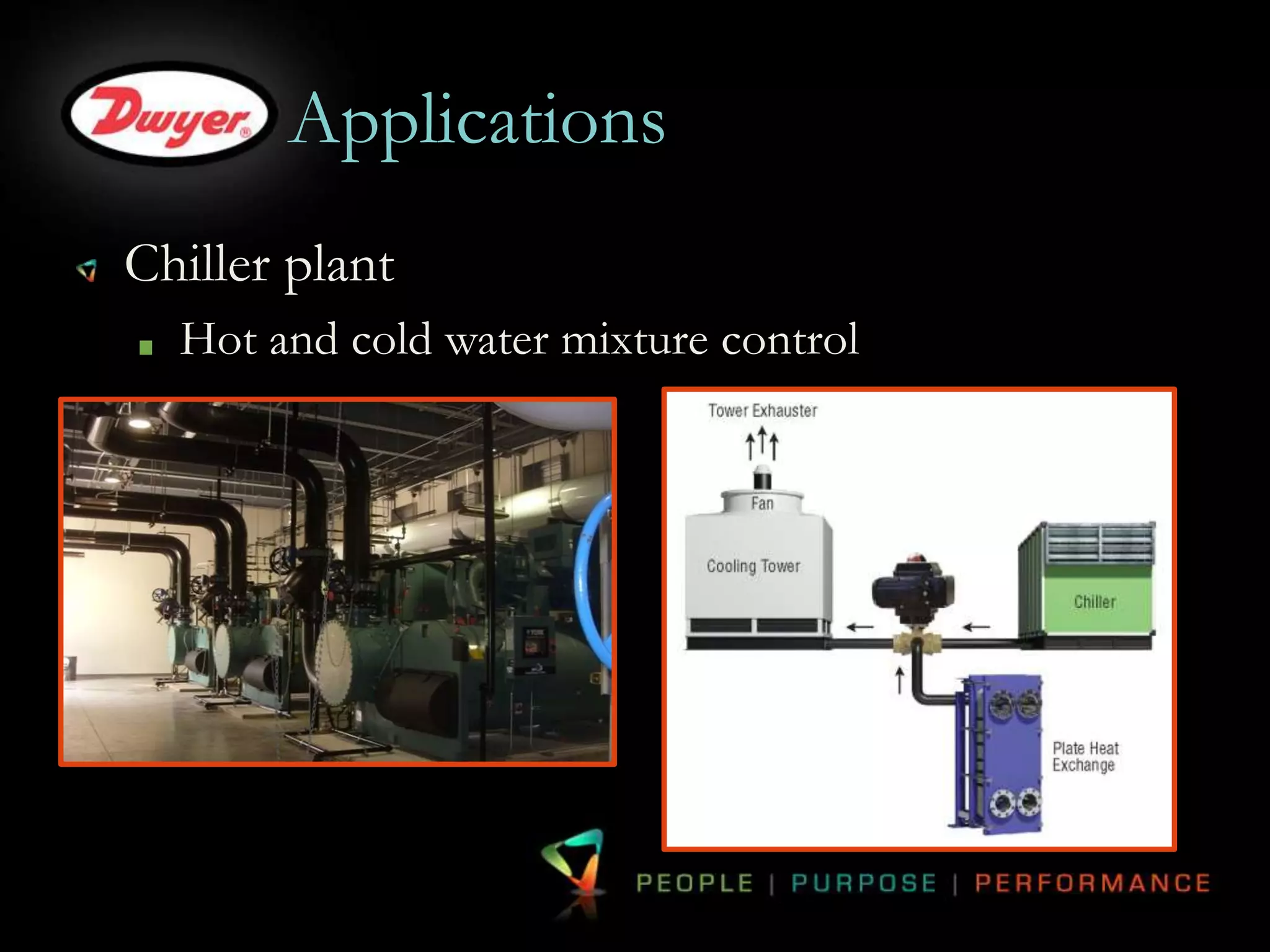

The document outlines various valve automation products from Dwyer Instruments, Inc., providing specifications, features, and applications for each type. It includes information on 2-way and 3-way stainless steel ball valves, tri-clamp valves, flanged valves, socket weld valves, v-ball valves, butterfly valves, and actuators. The materials are intended as a resource for customers and employees, with restrictions on reproduction and use of company trademarks.