The document discusses ultrasonic testing principles including:

- The 9.5 day course aims to train participants to obtain skills and knowledge for ultrasonic testing certification.

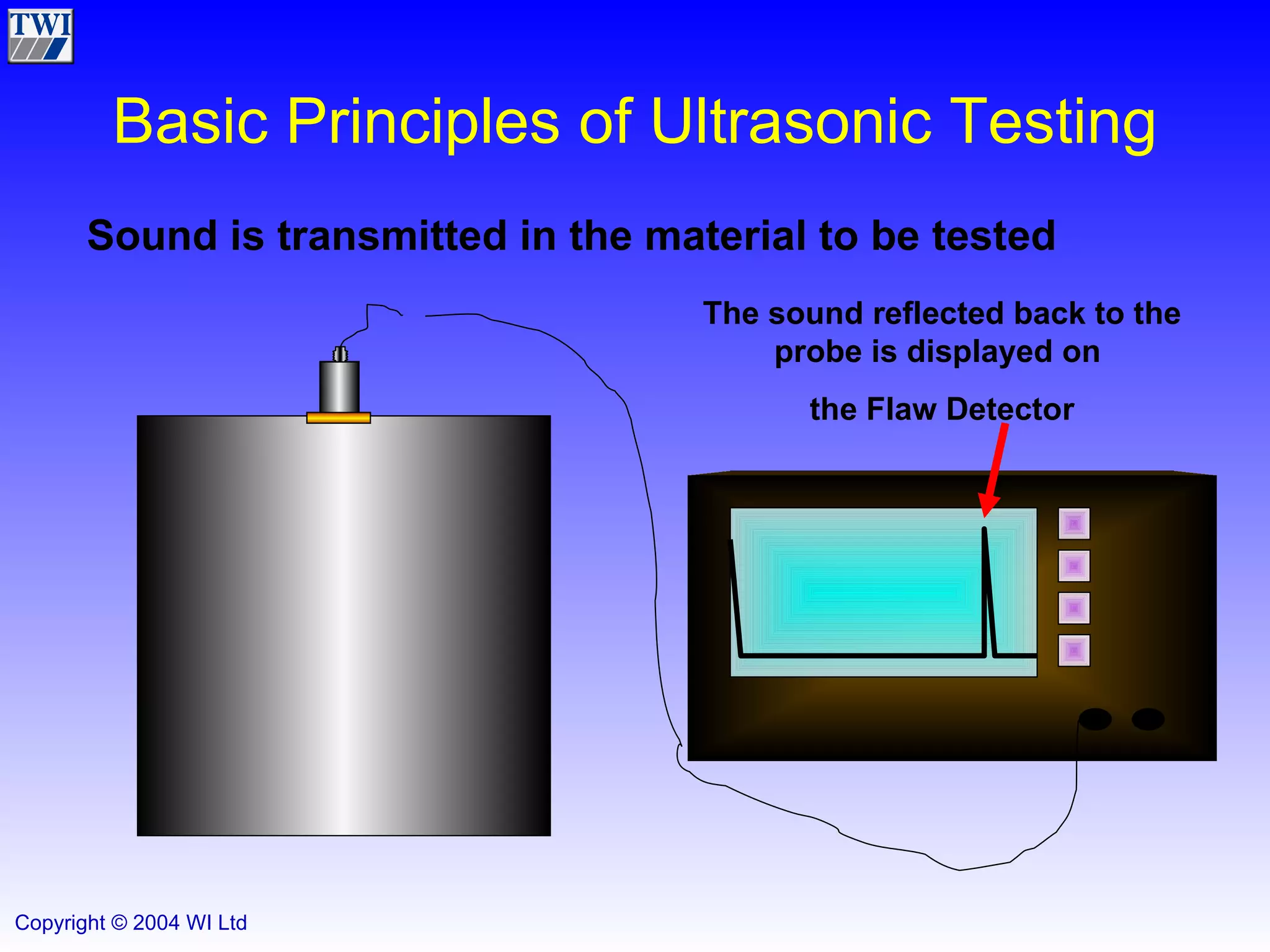

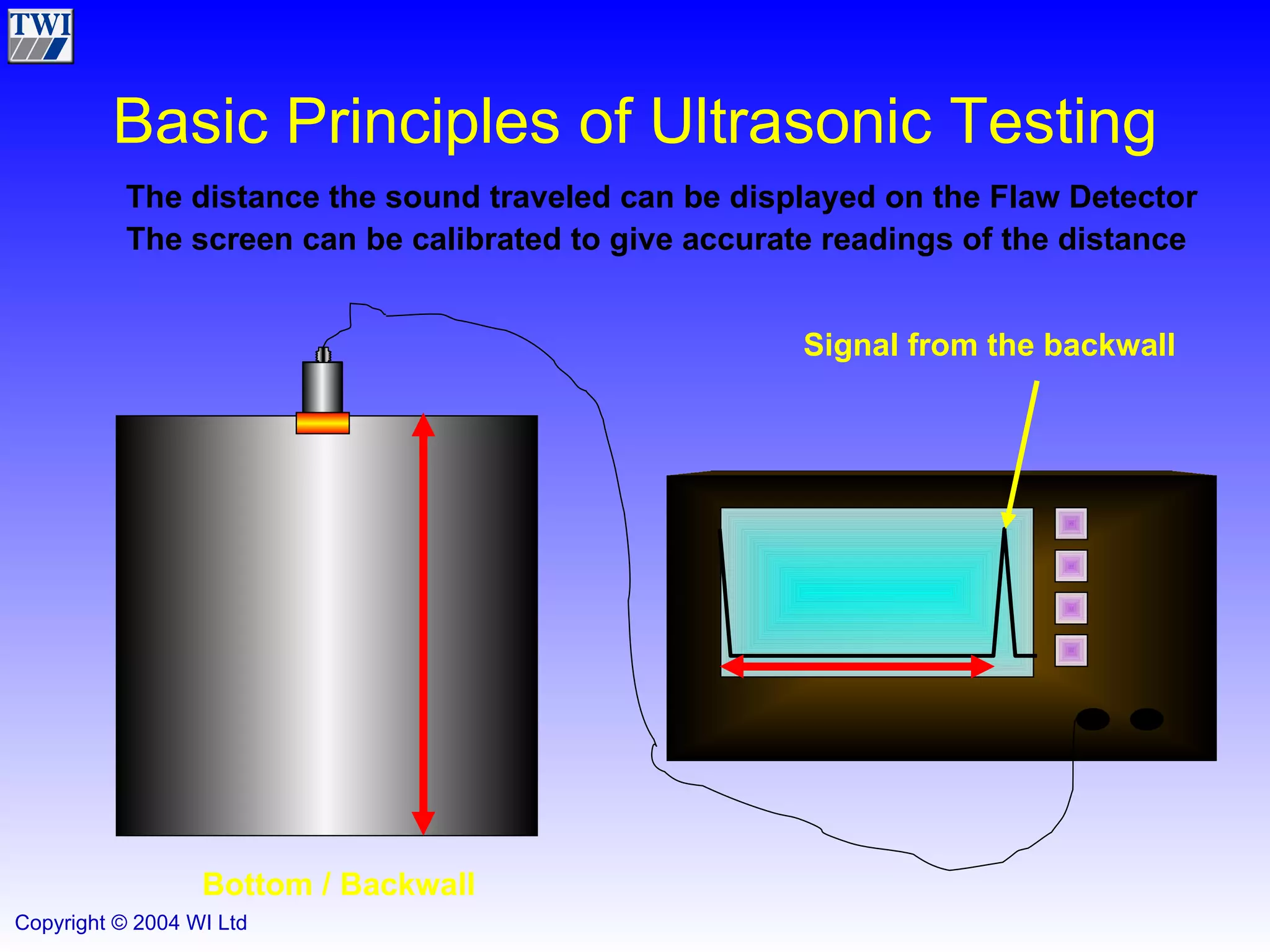

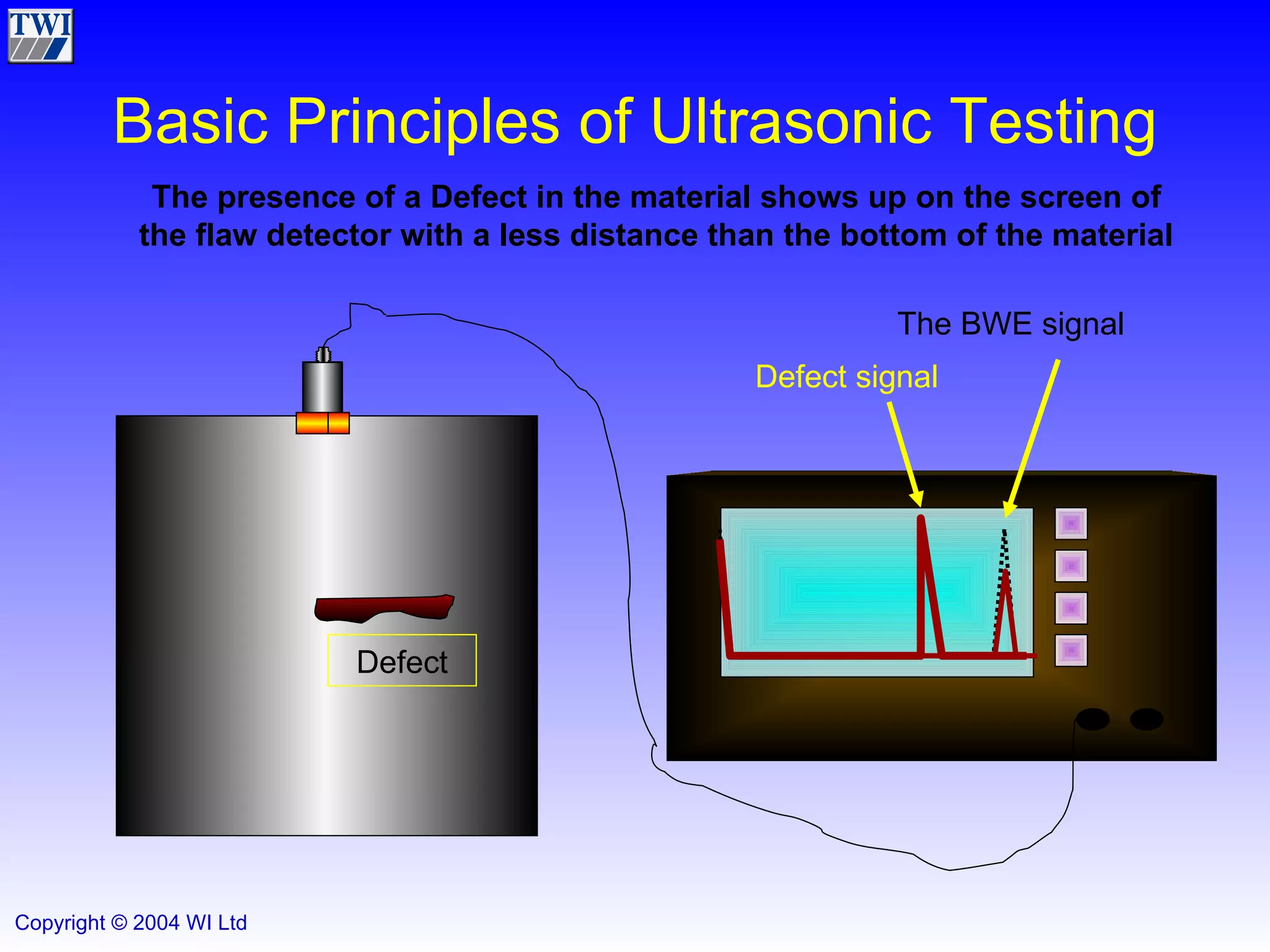

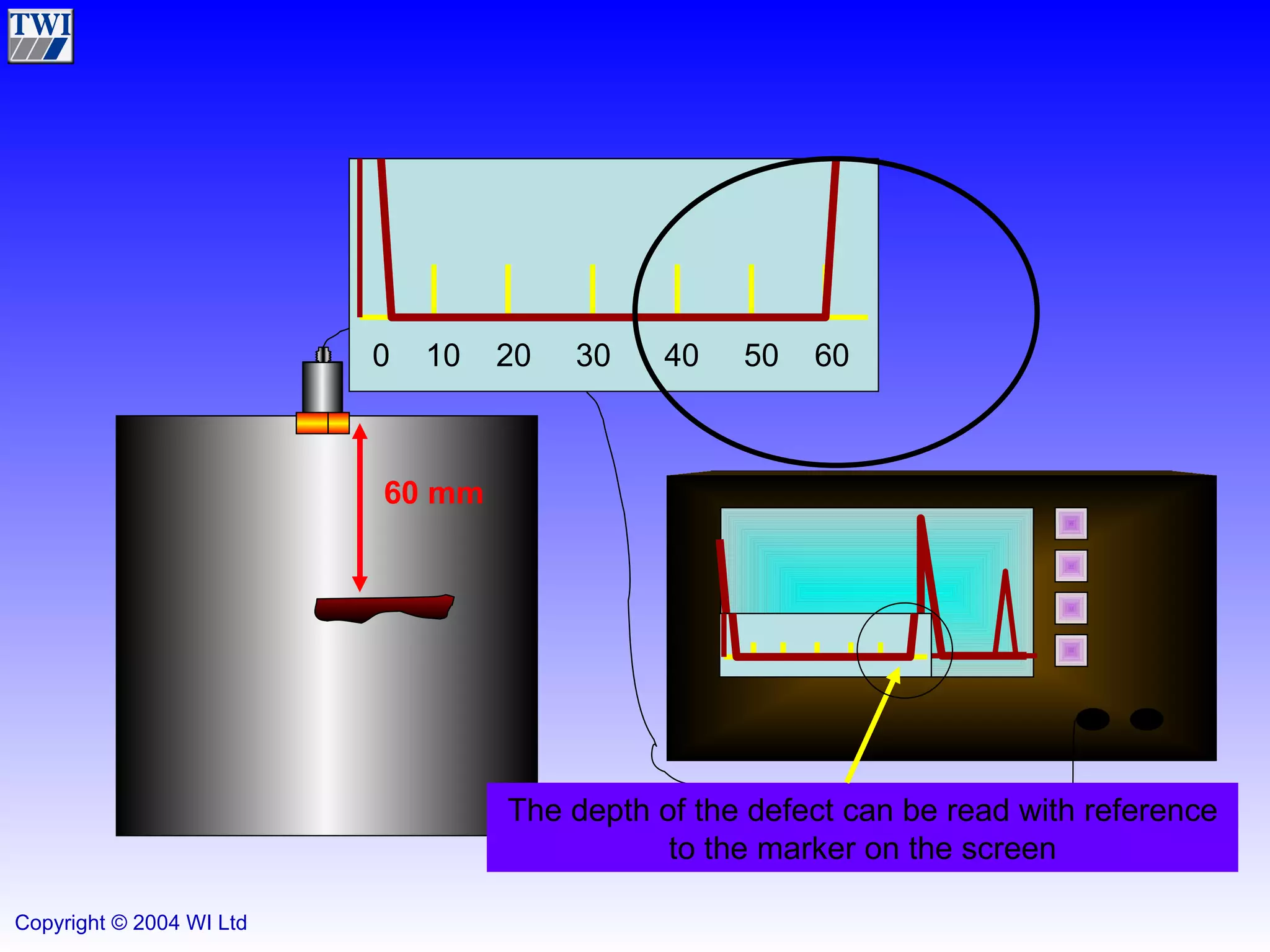

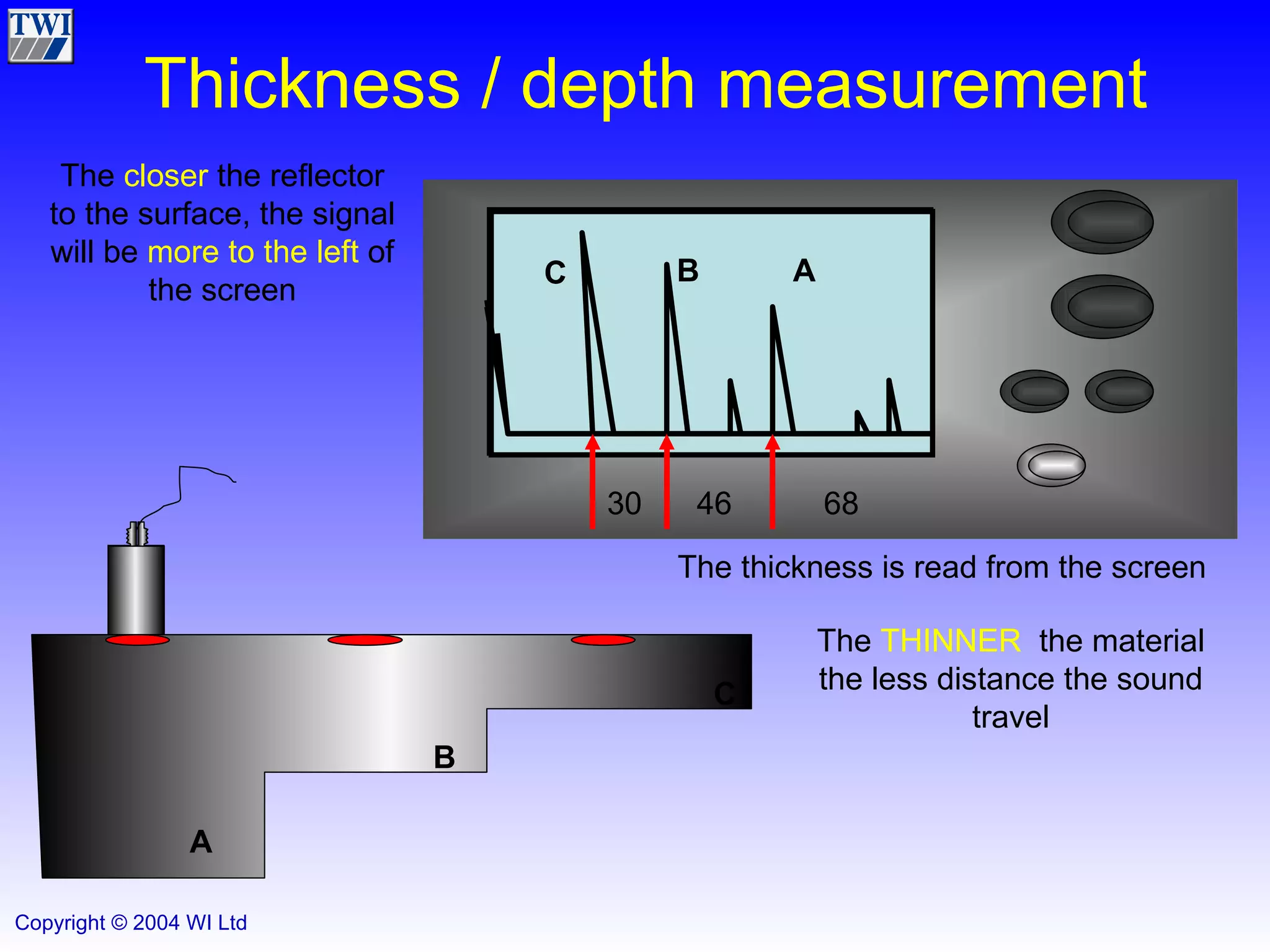

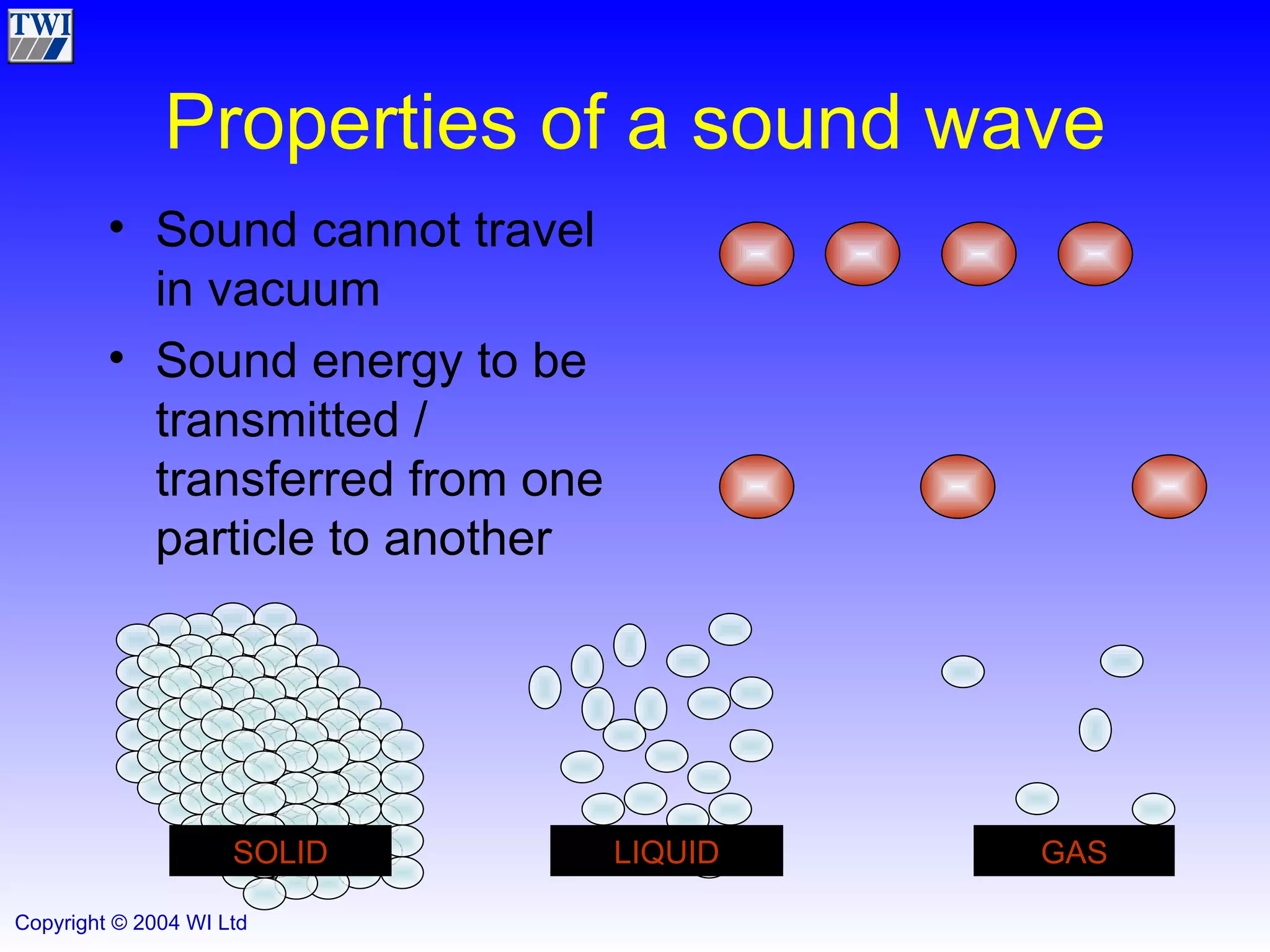

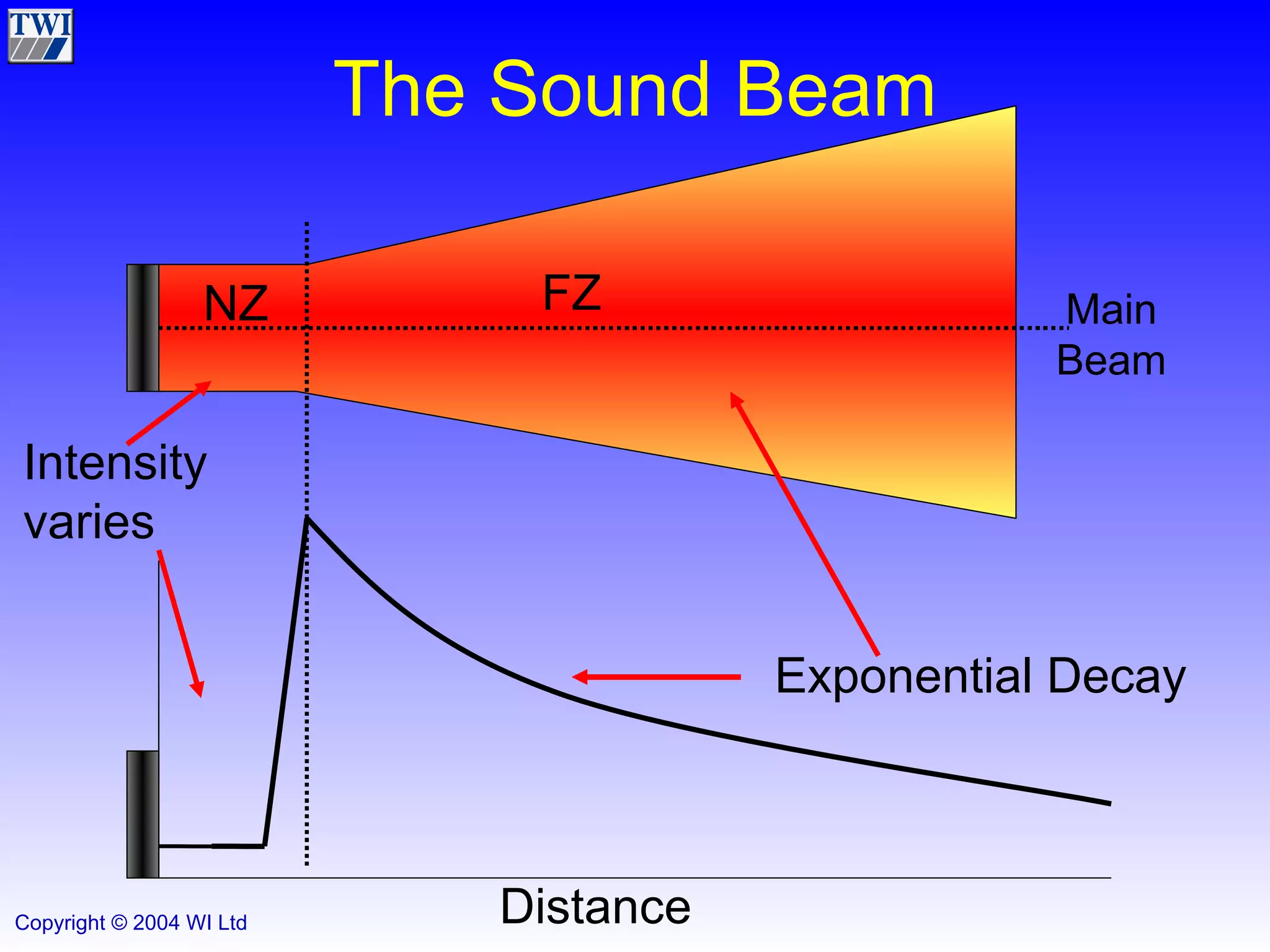

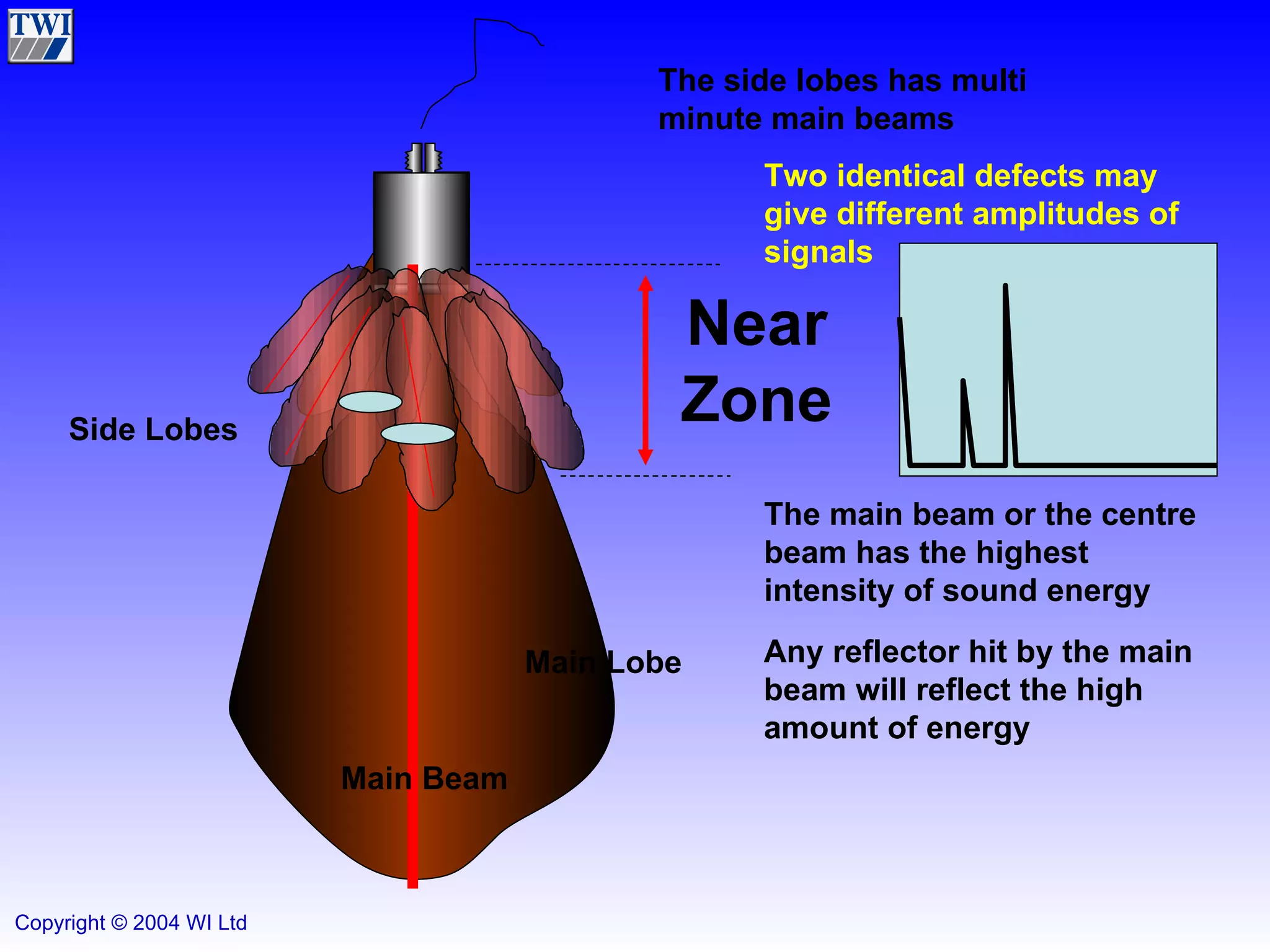

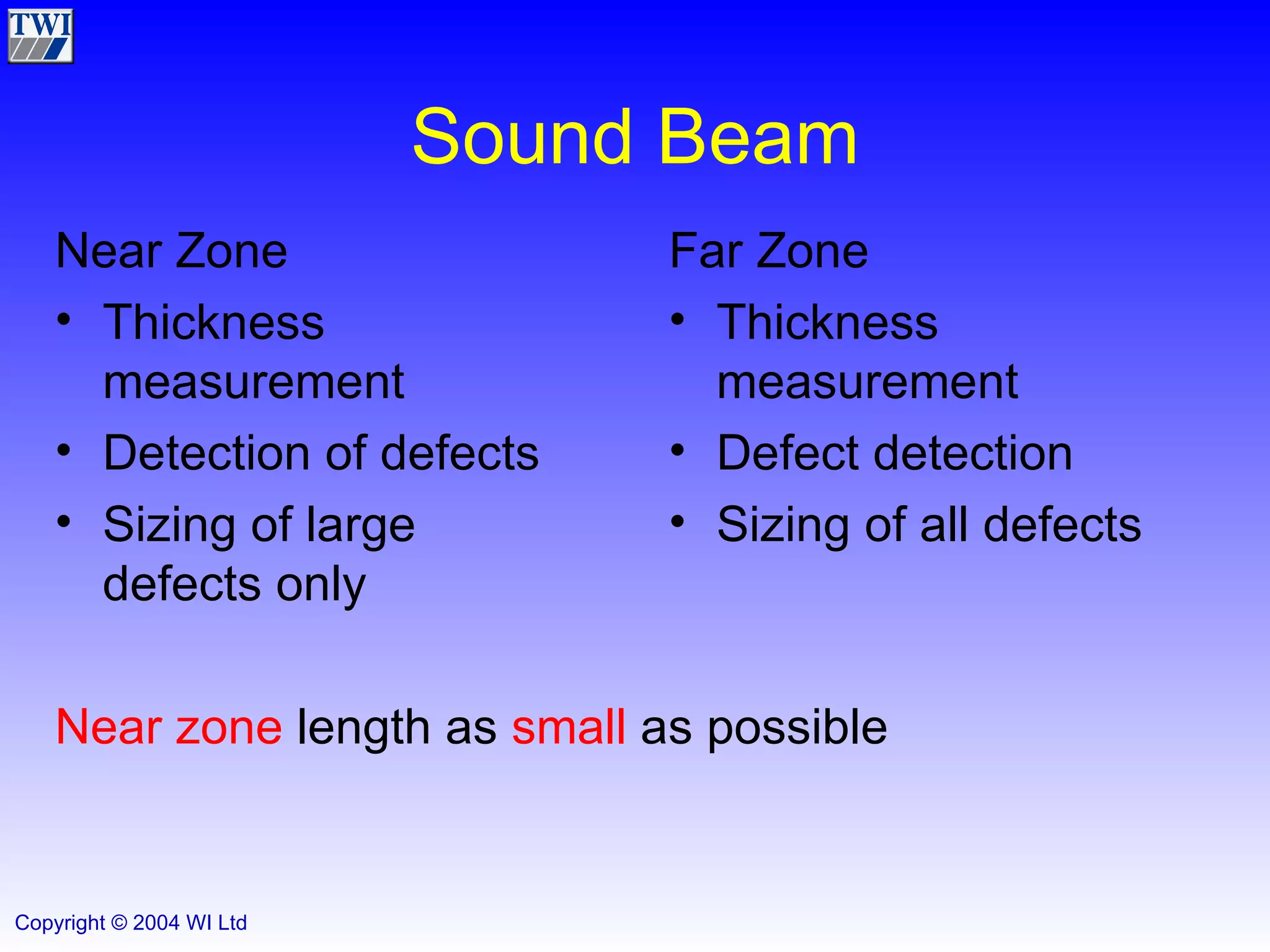

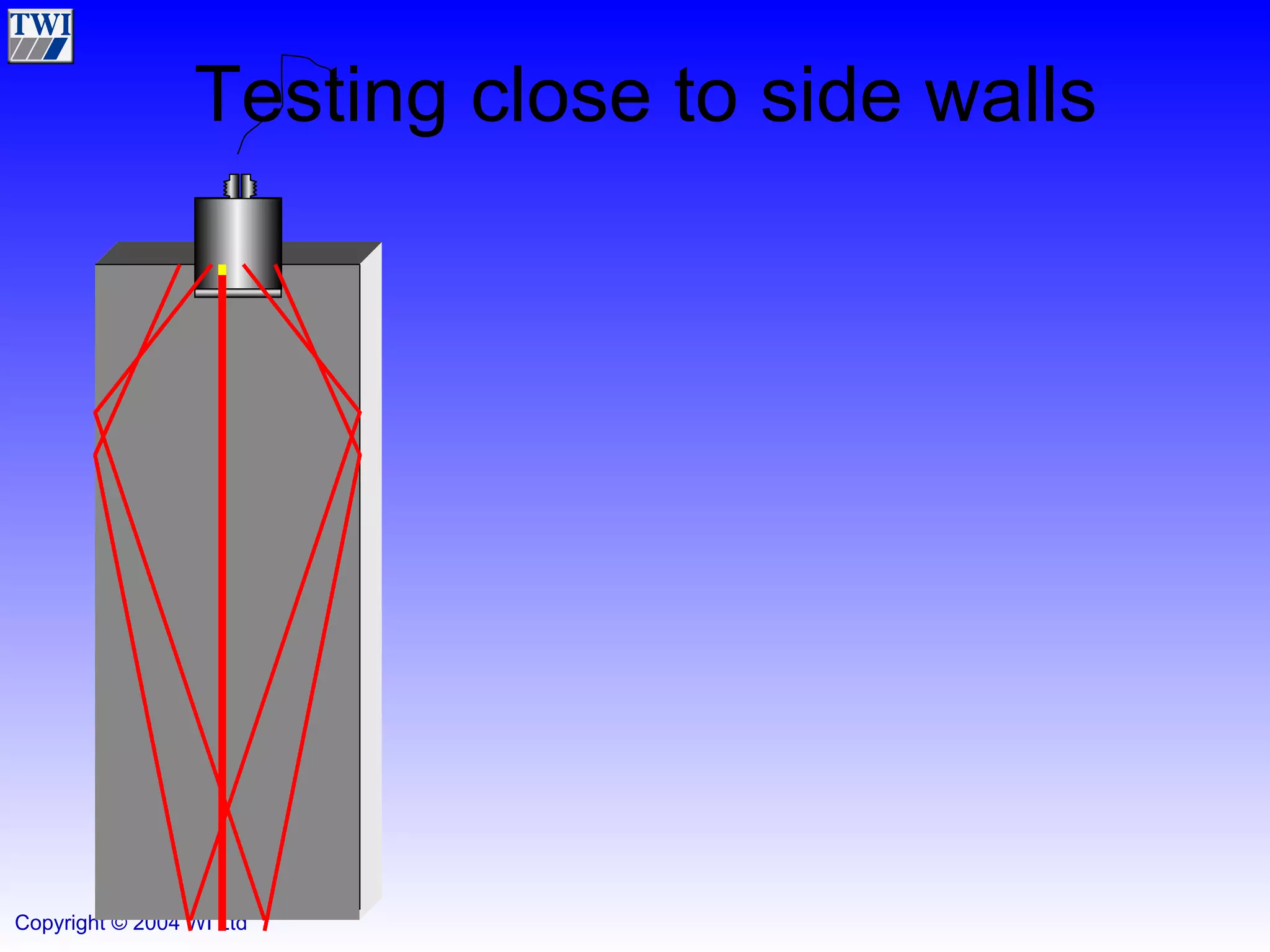

- Basic ultrasonic testing principles are explained such as how sound is transmitted through materials and defects are detected based on differences in signal travel time.

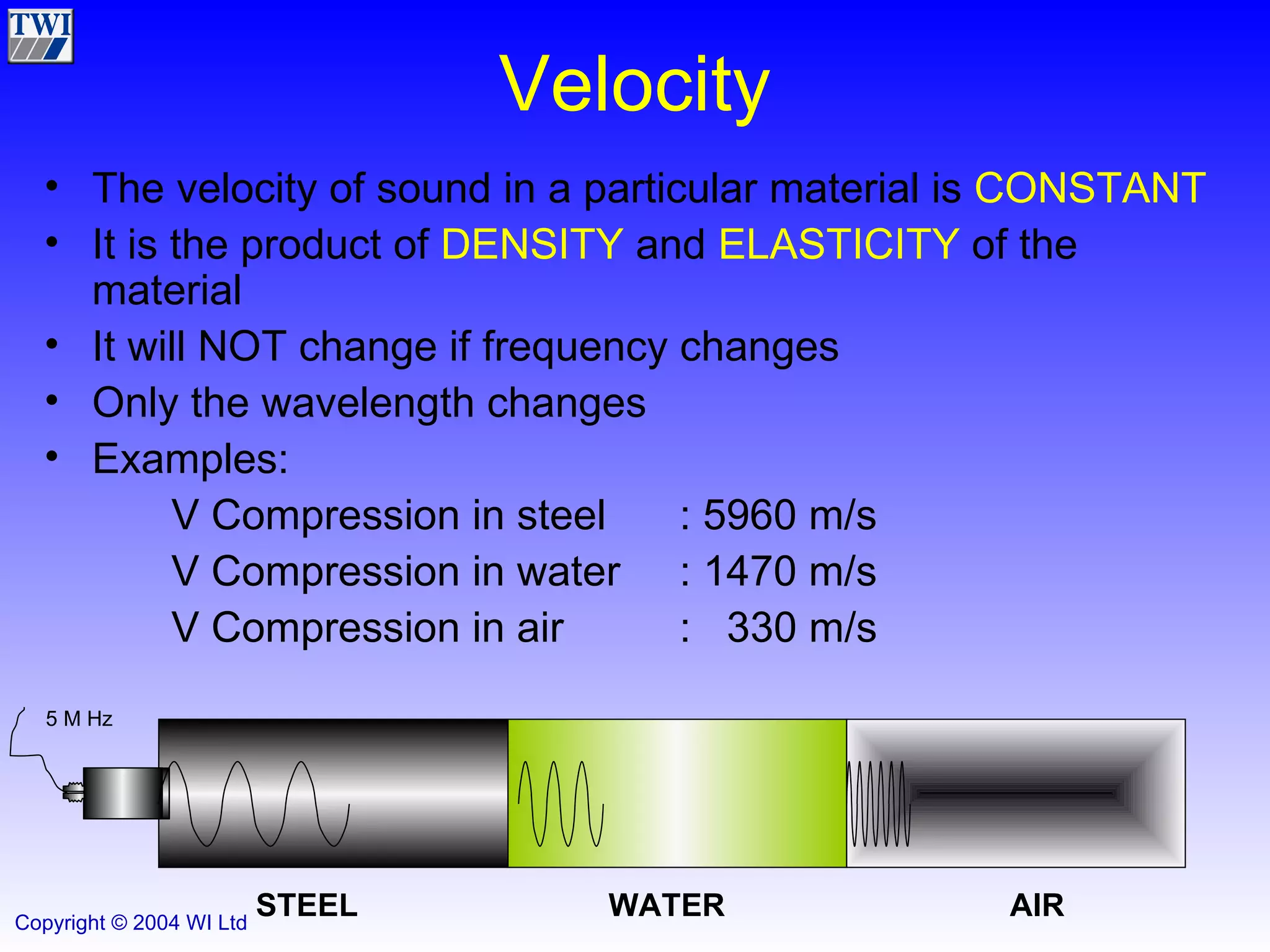

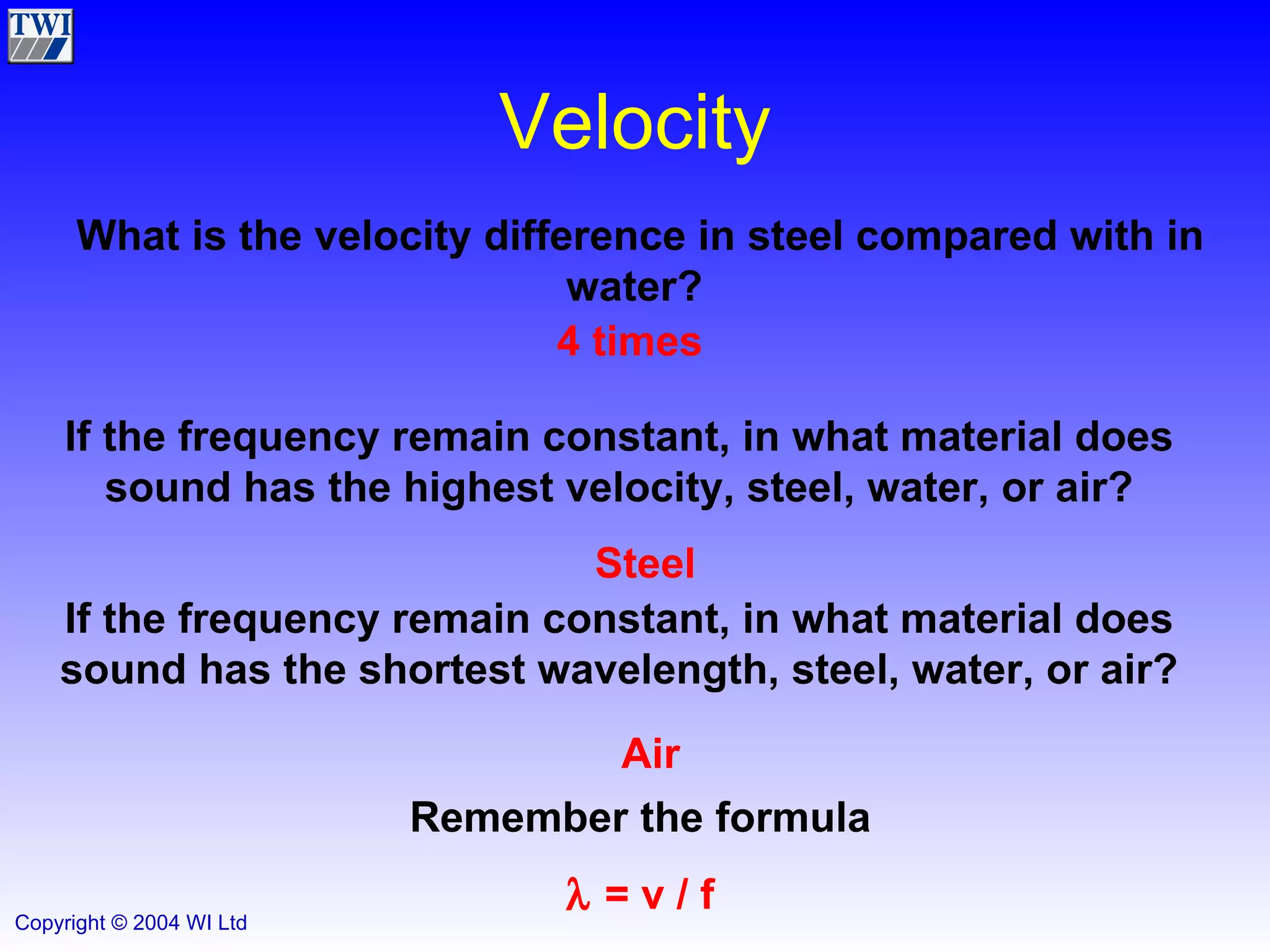

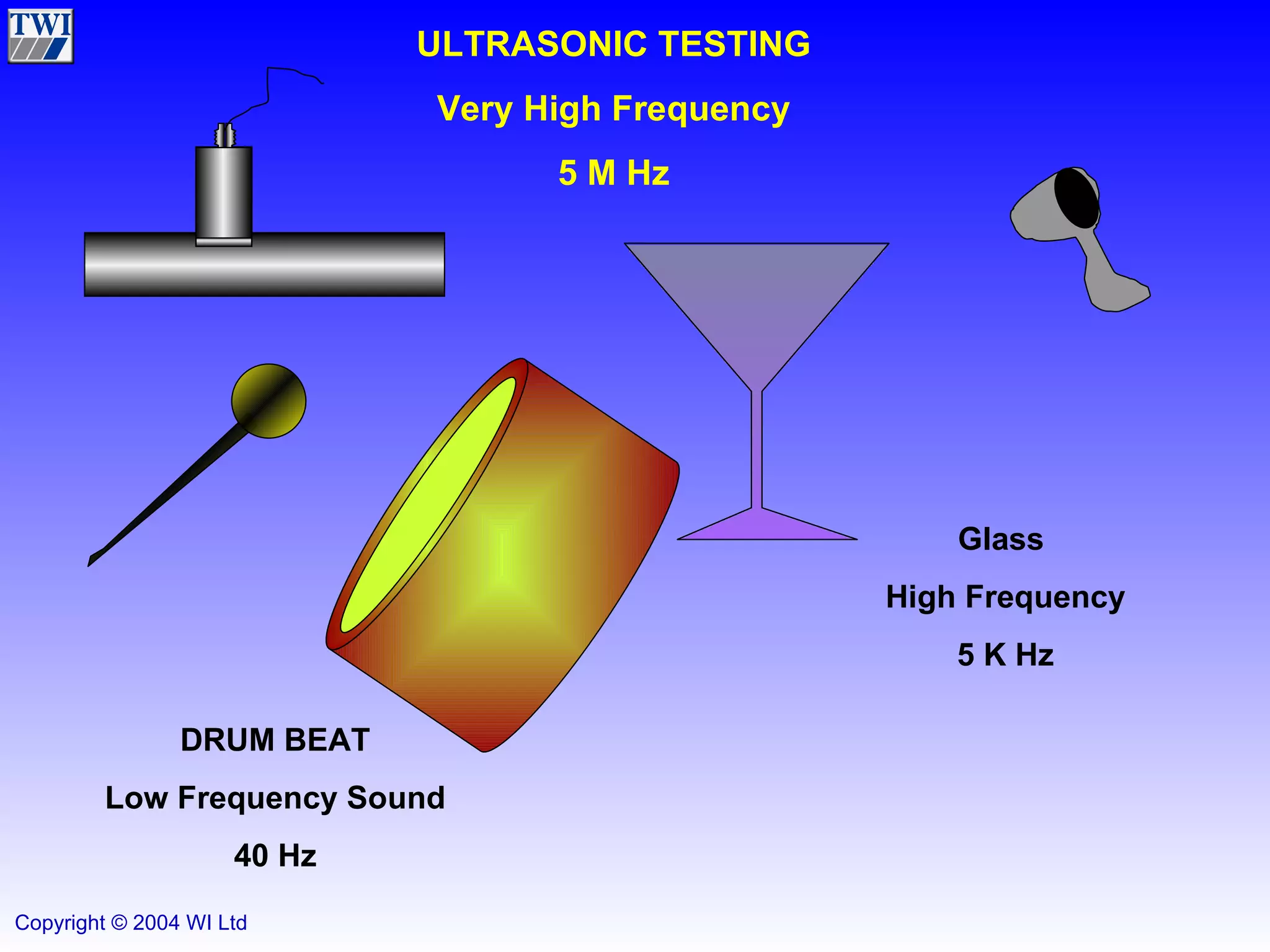

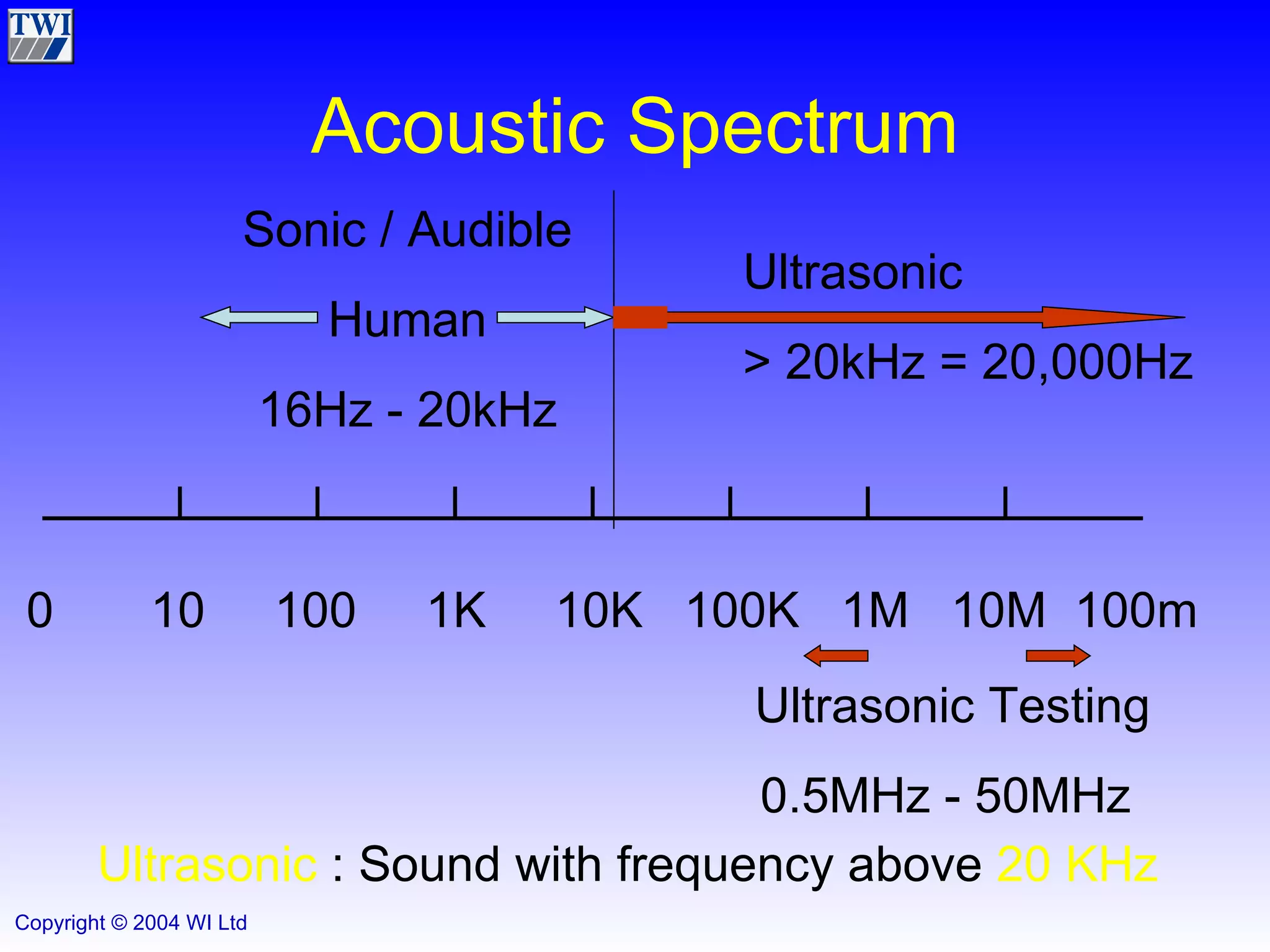

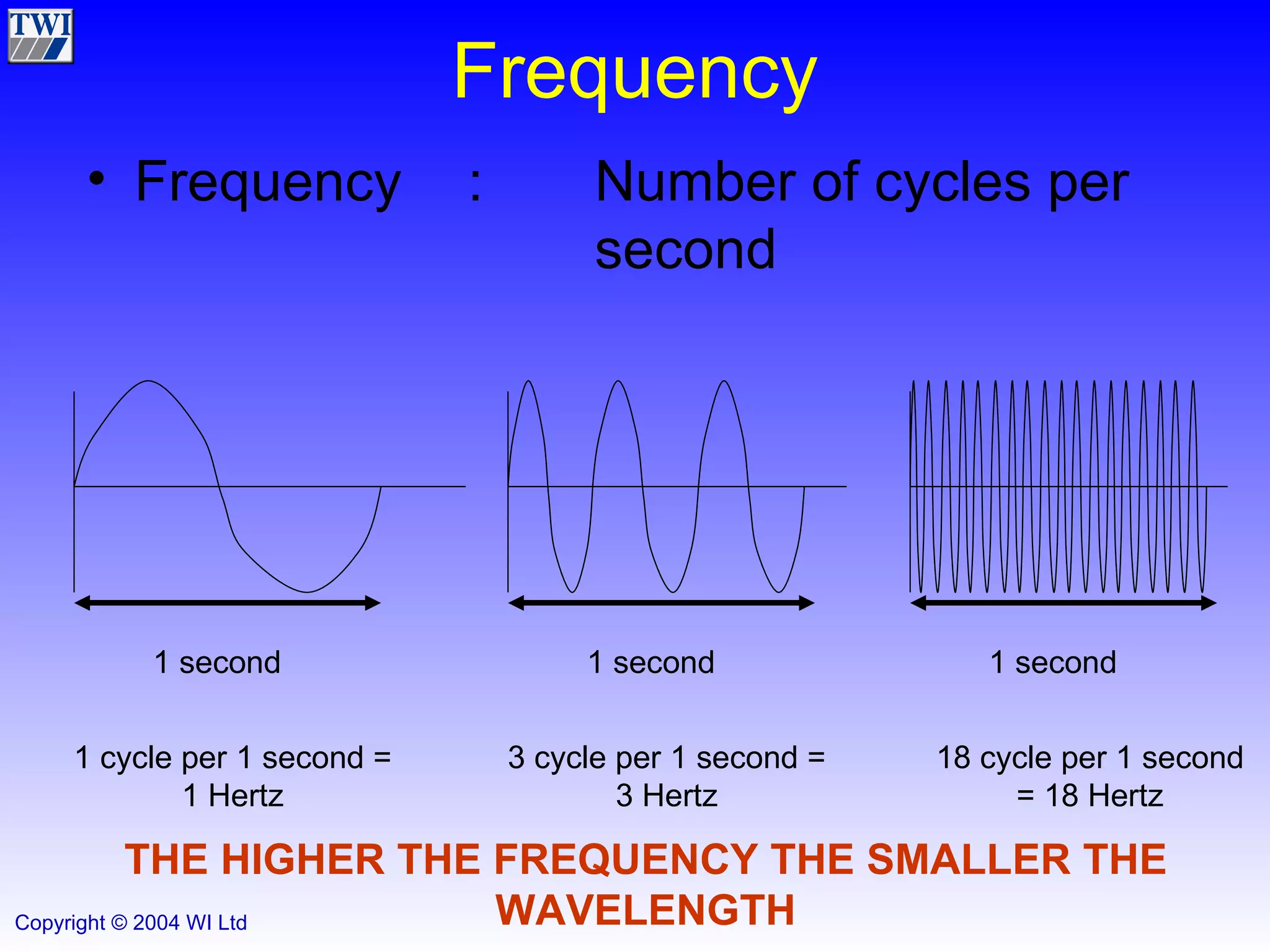

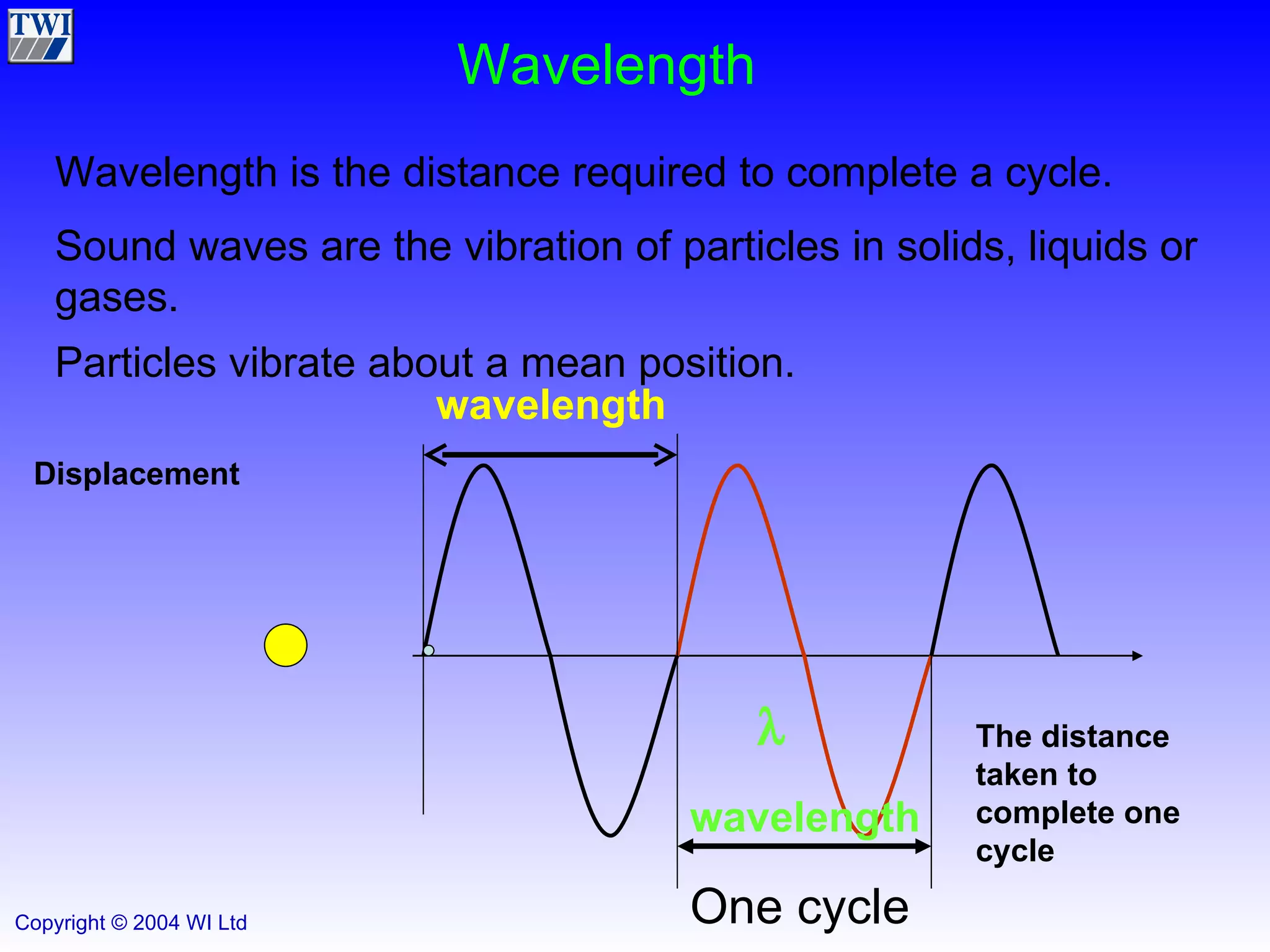

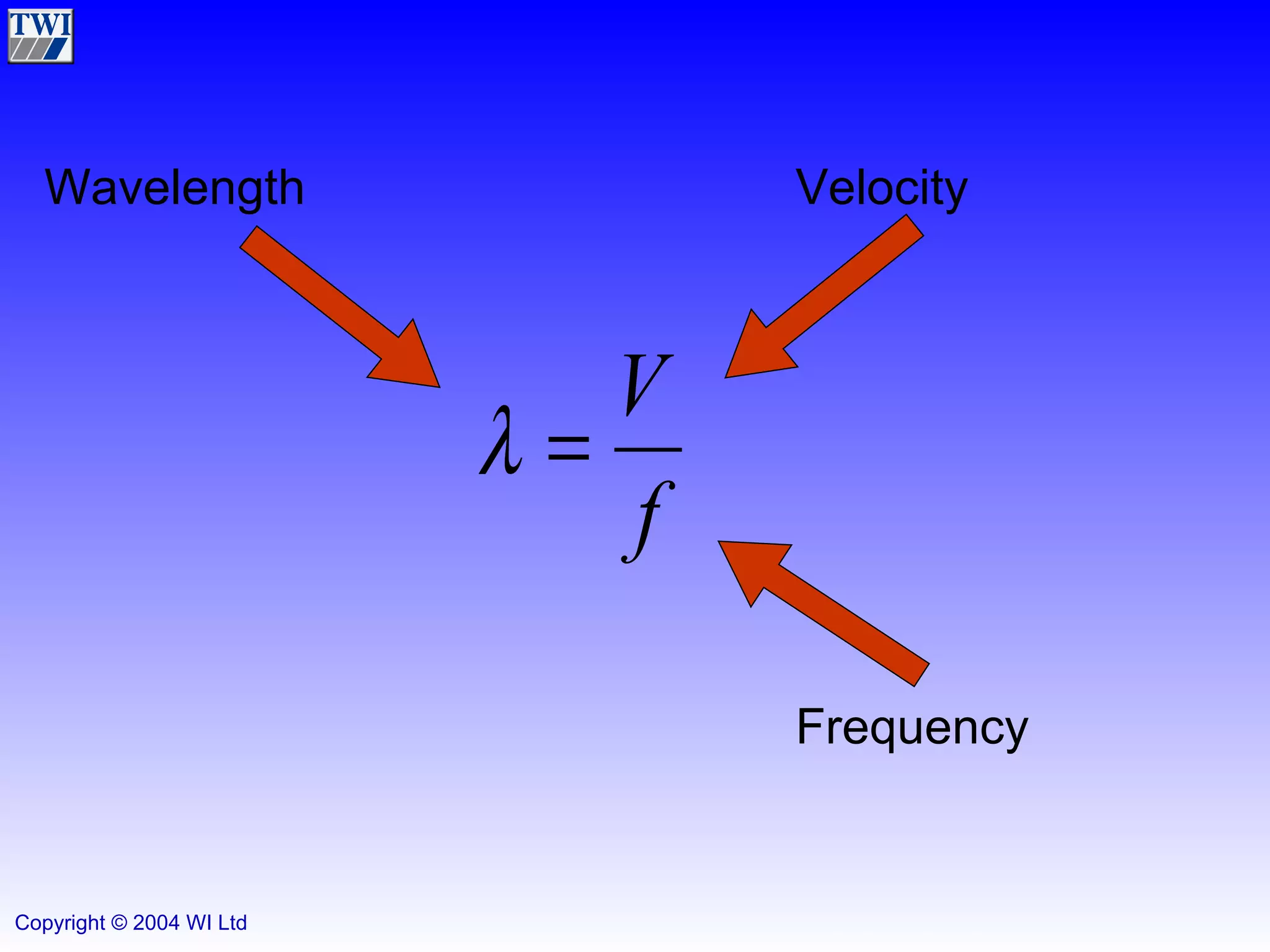

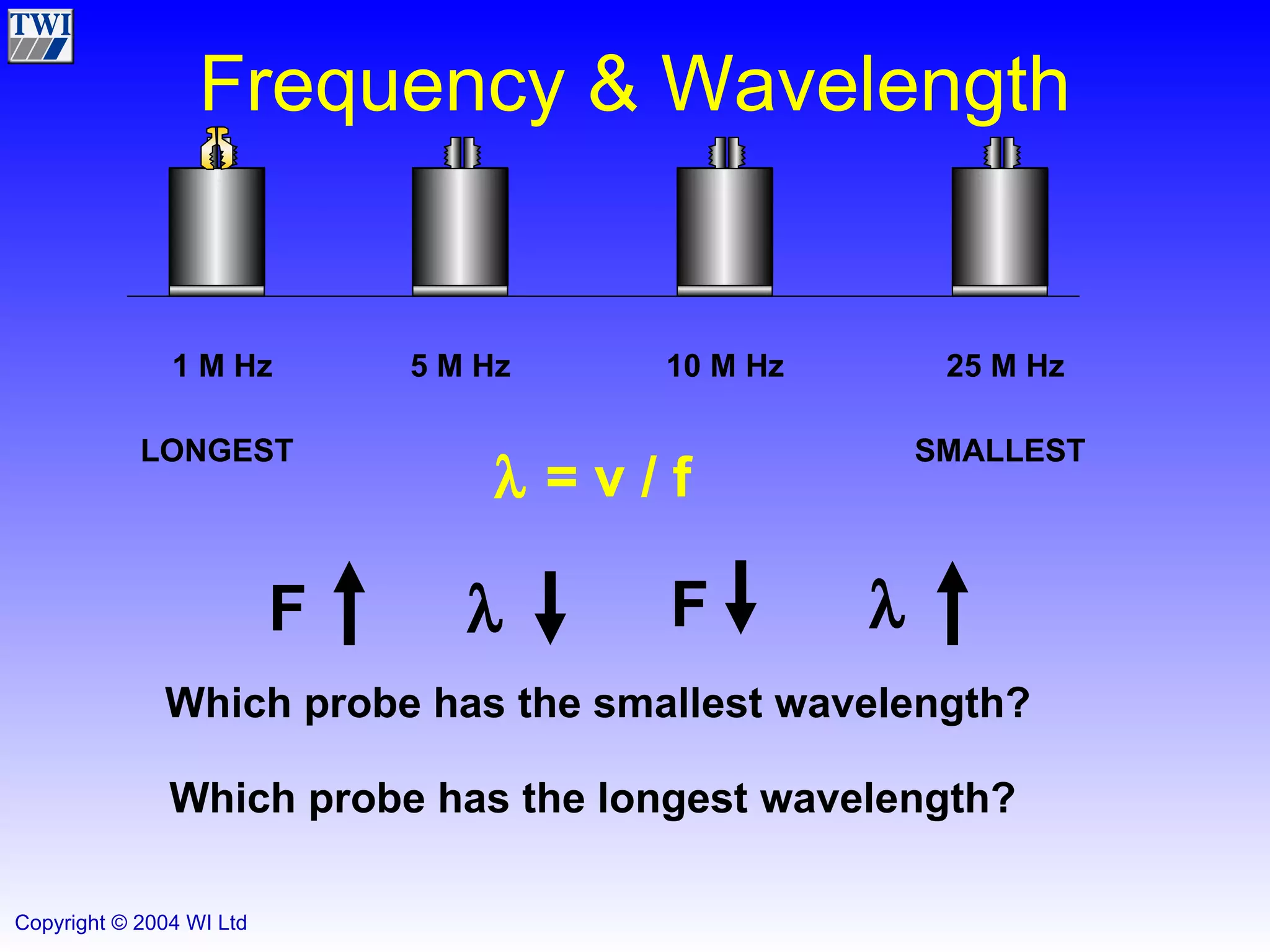

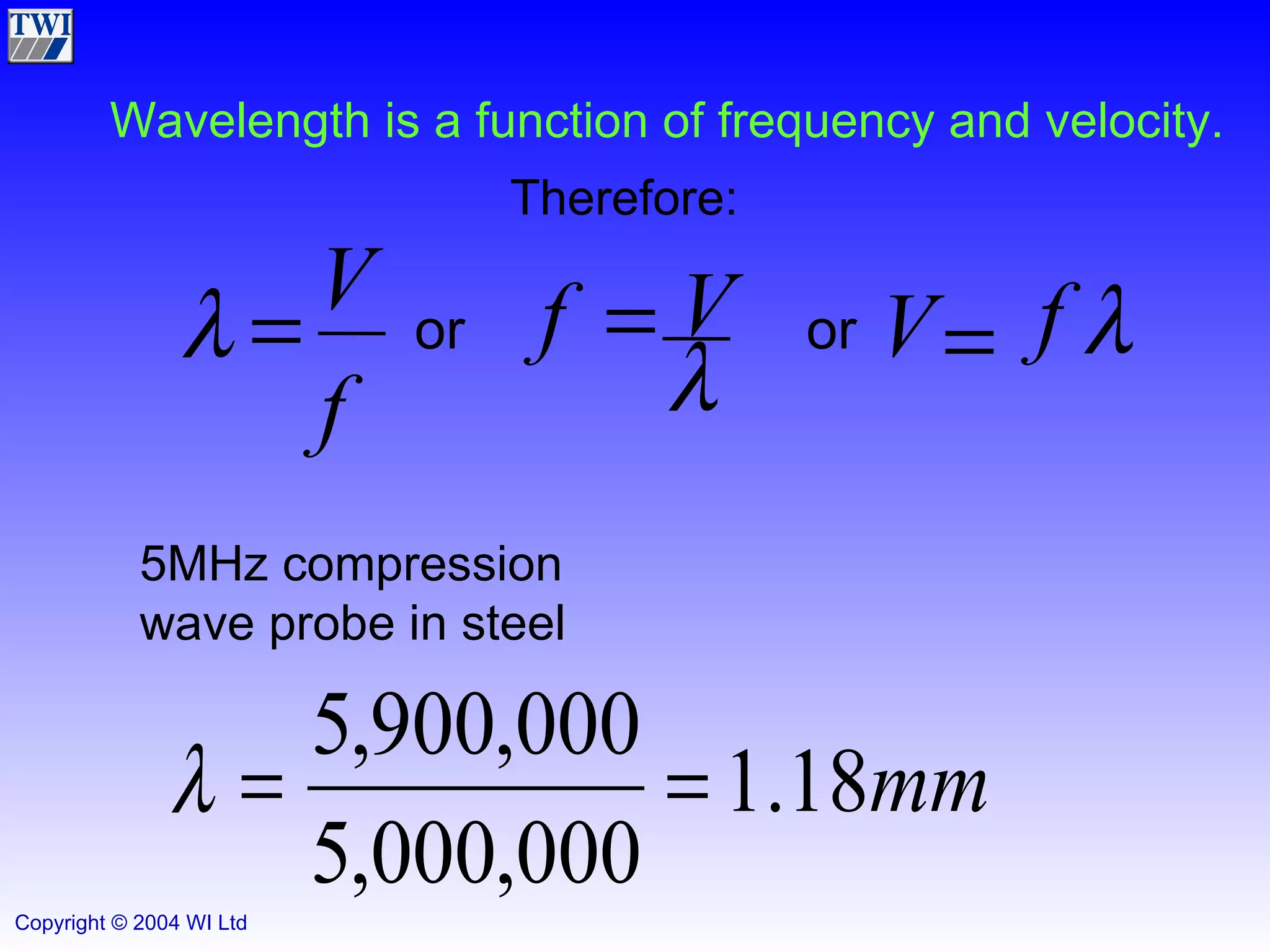

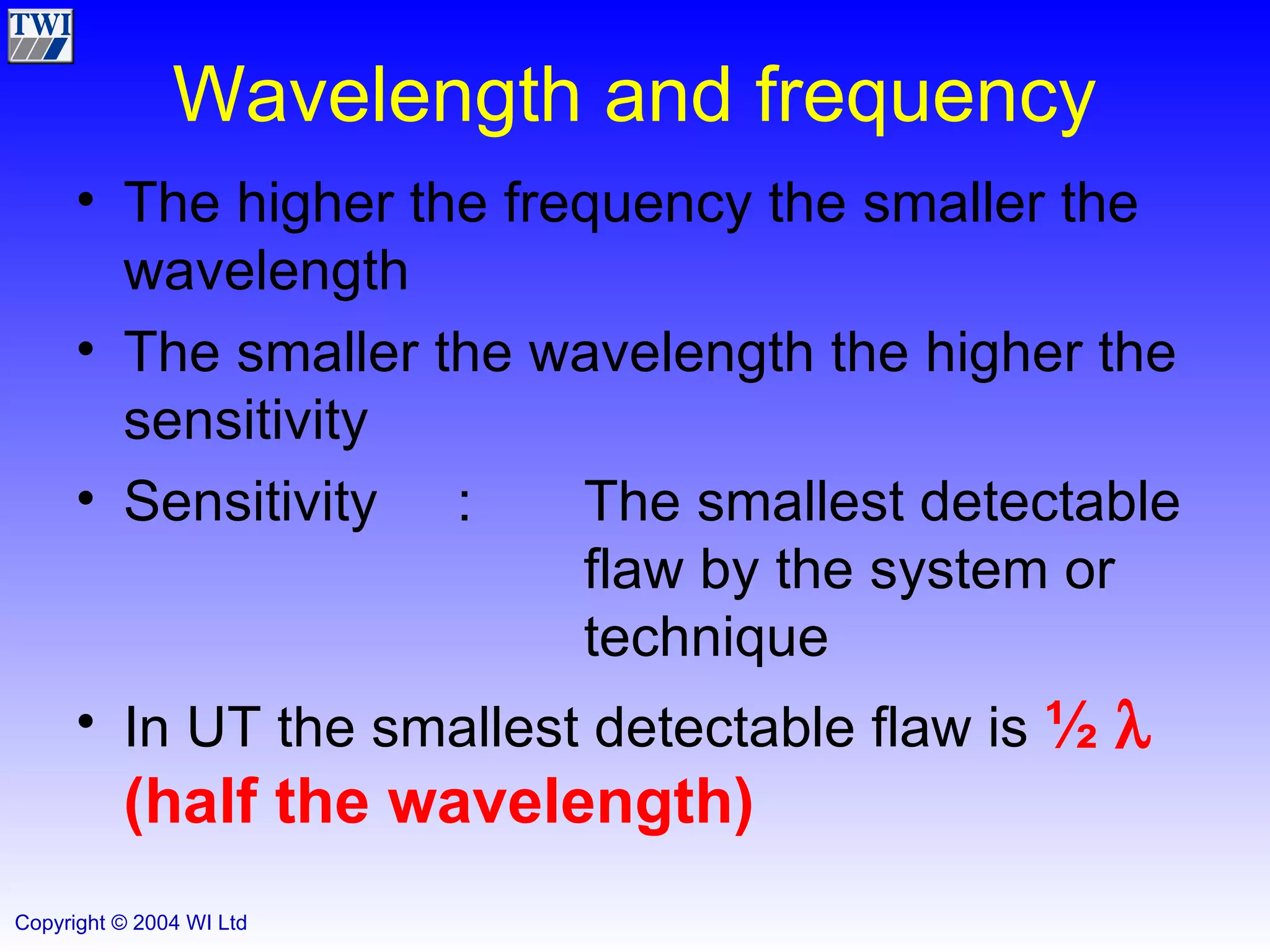

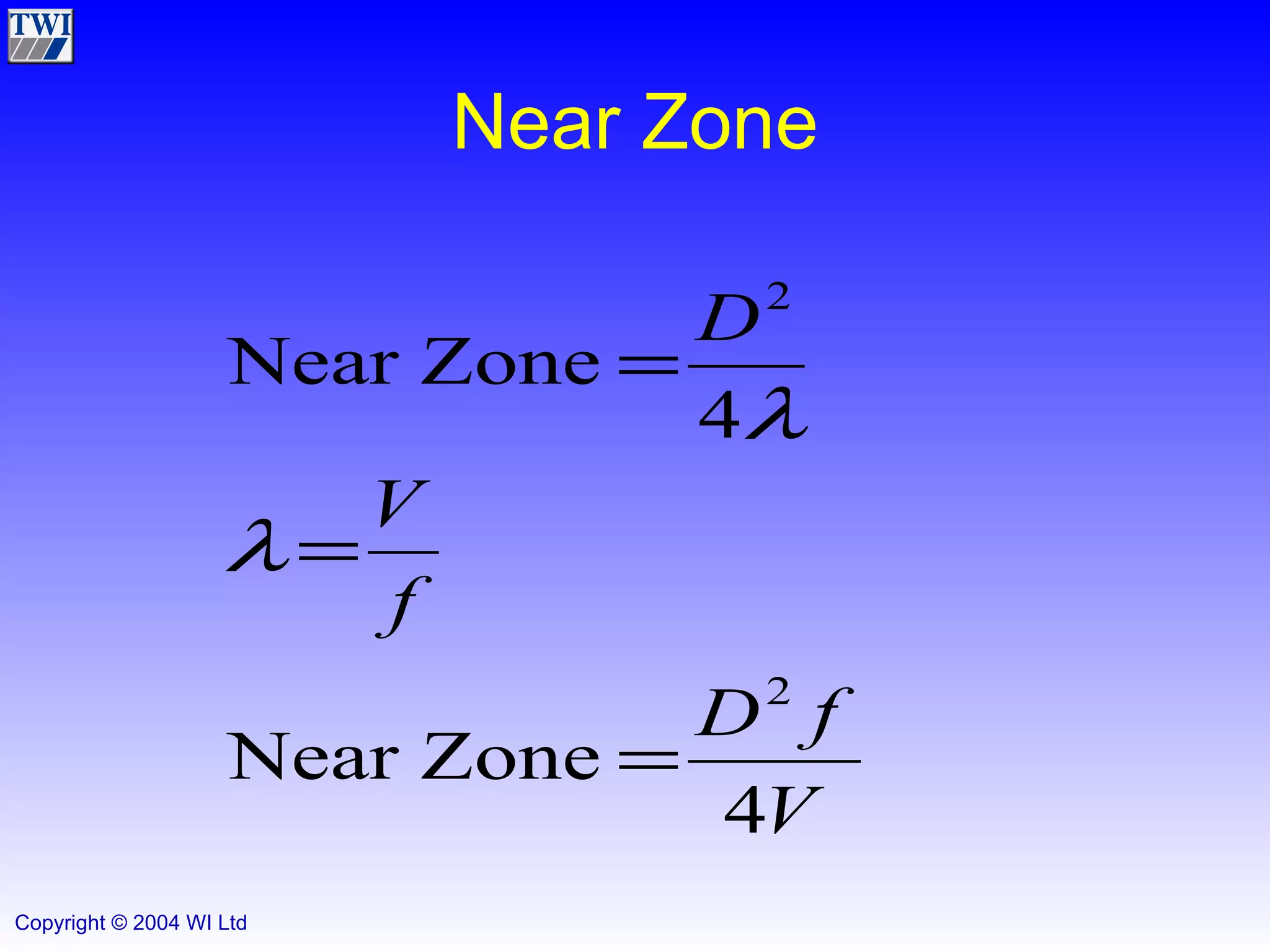

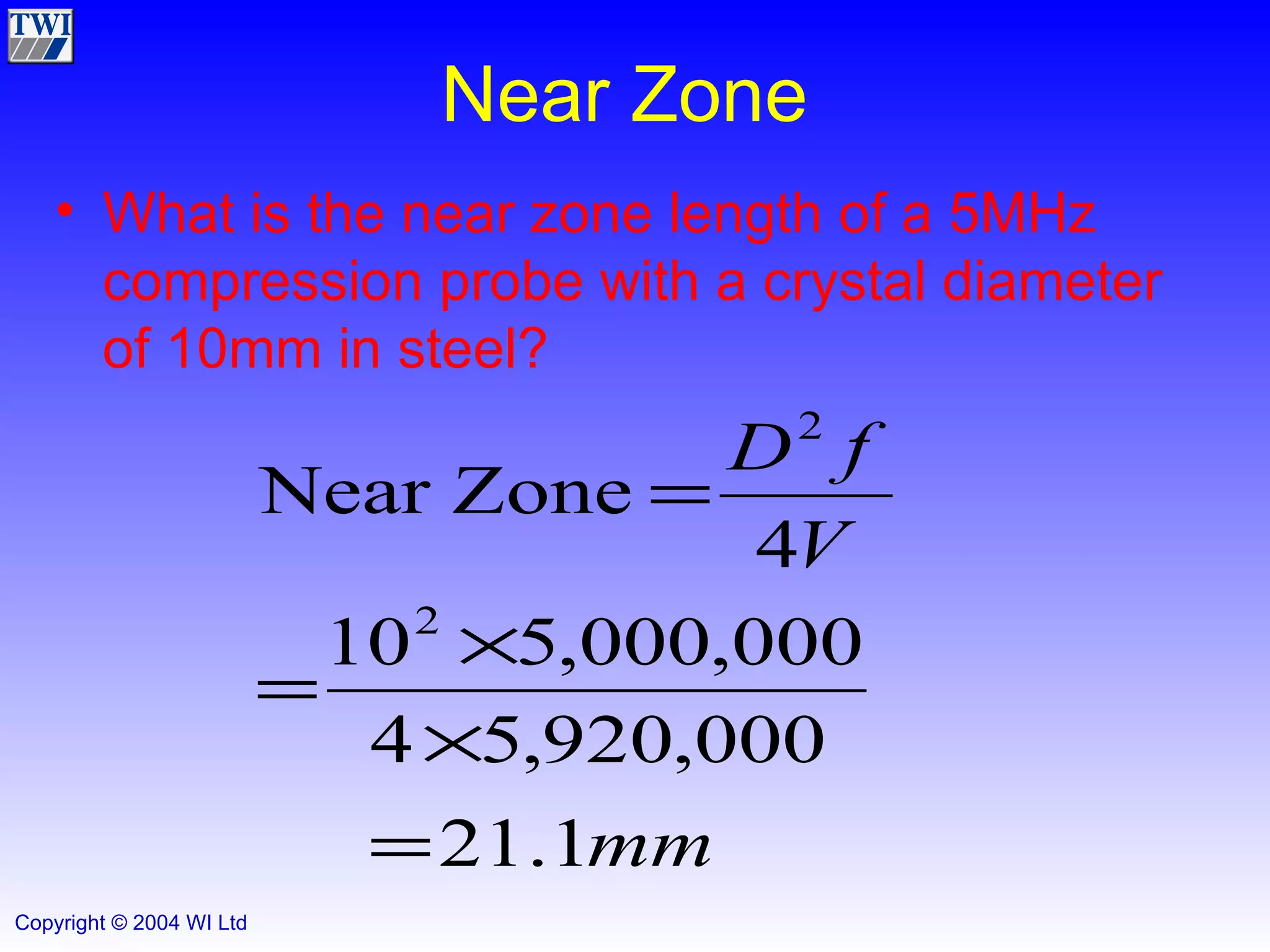

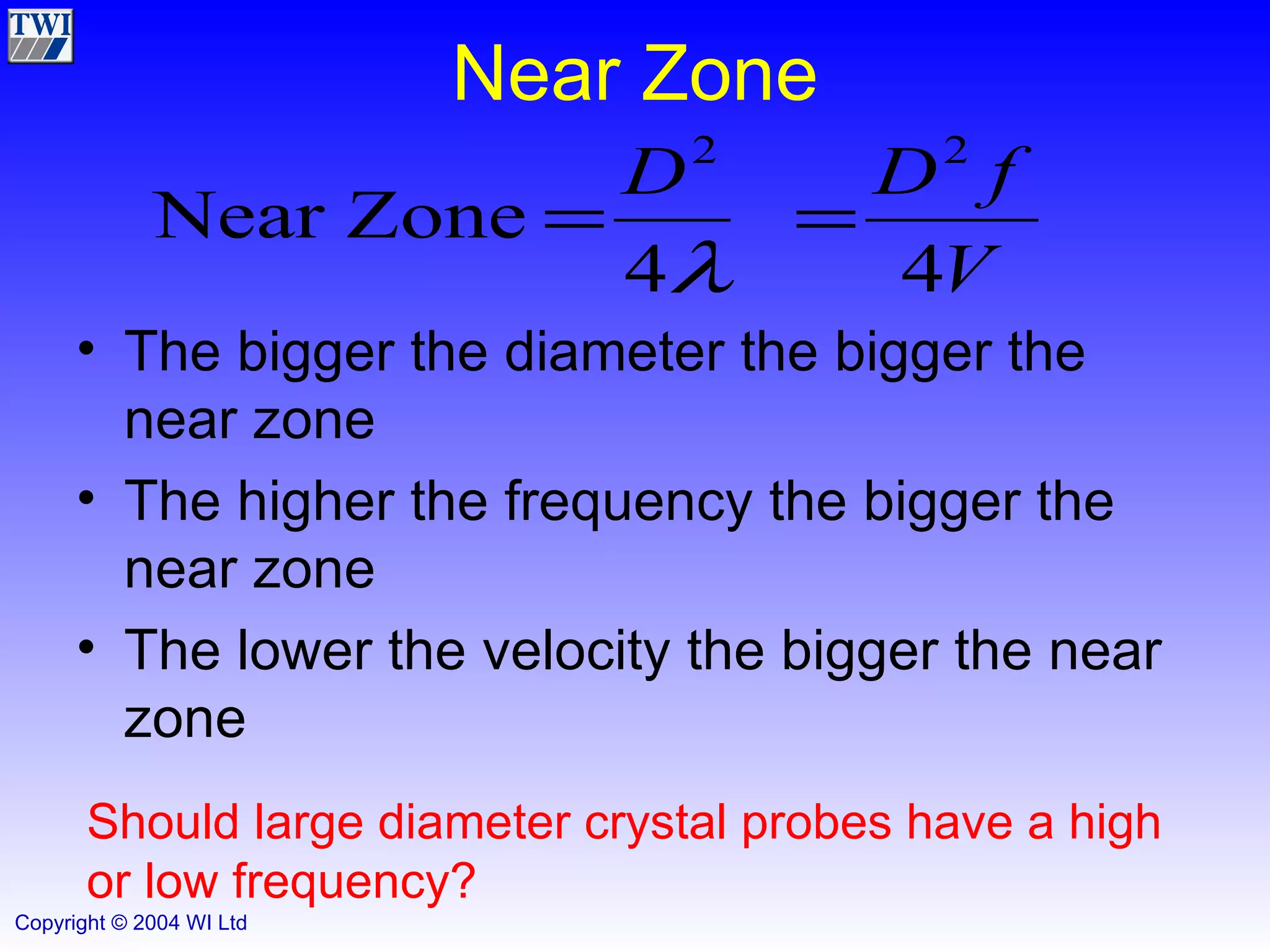

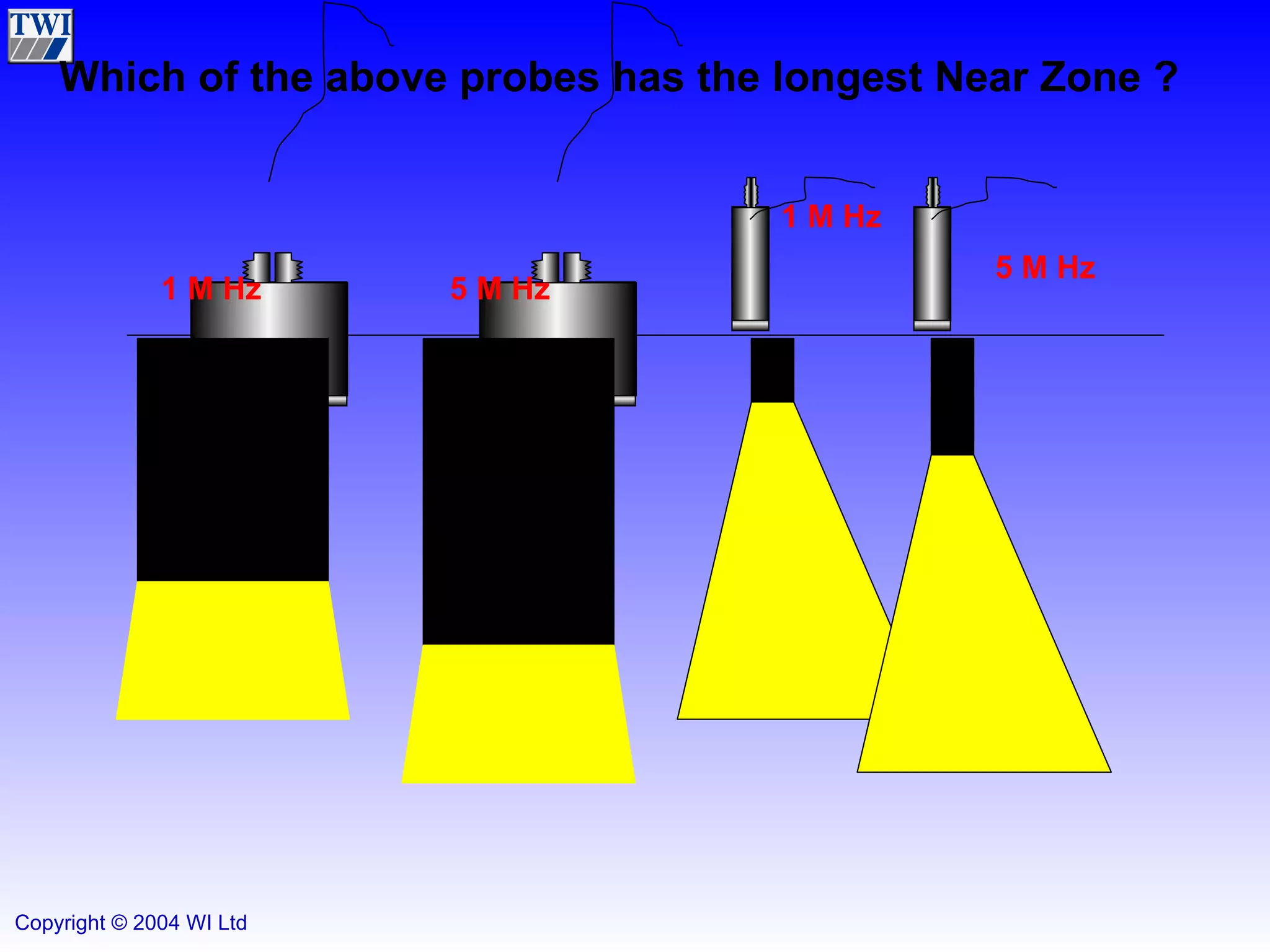

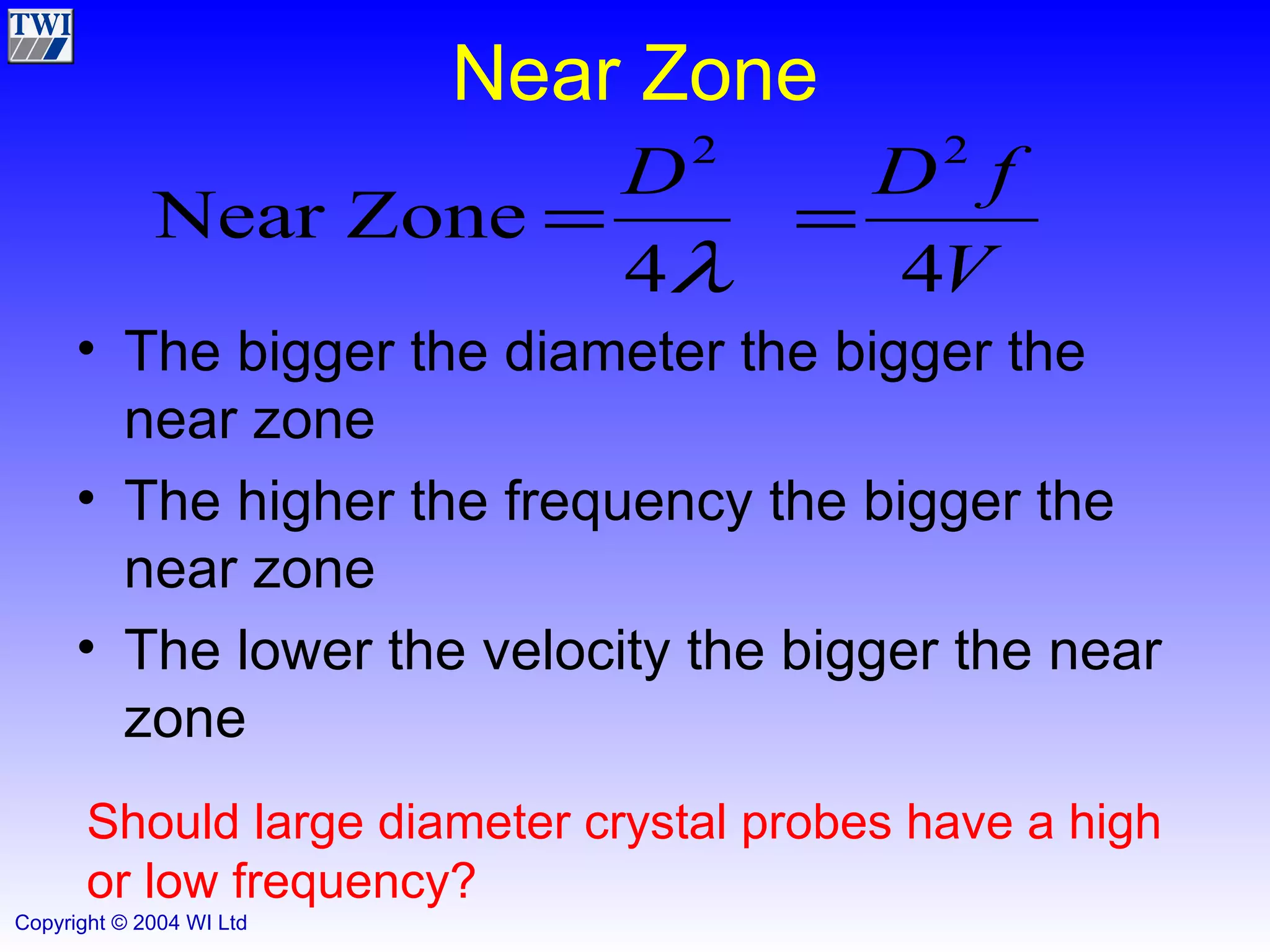

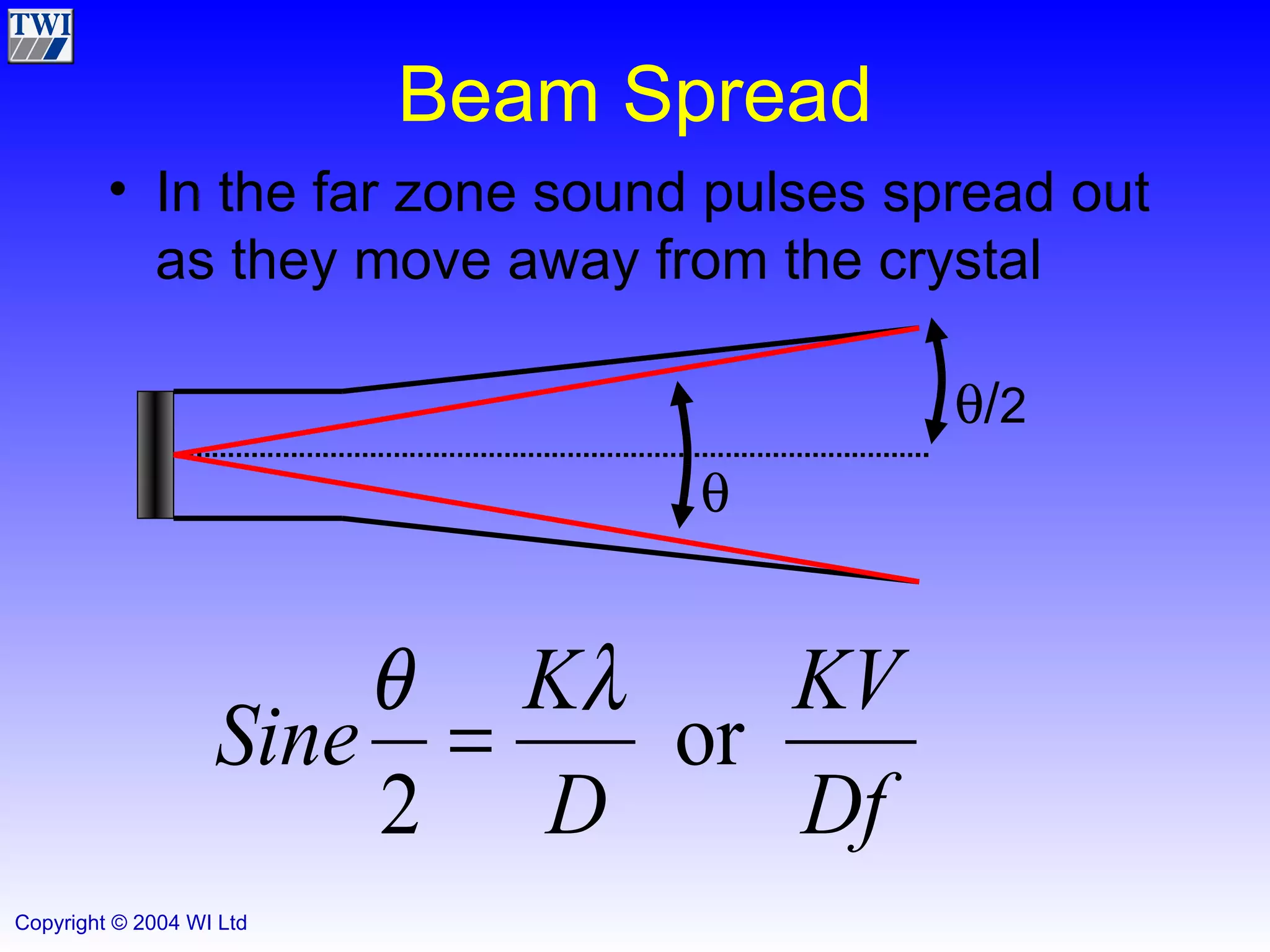

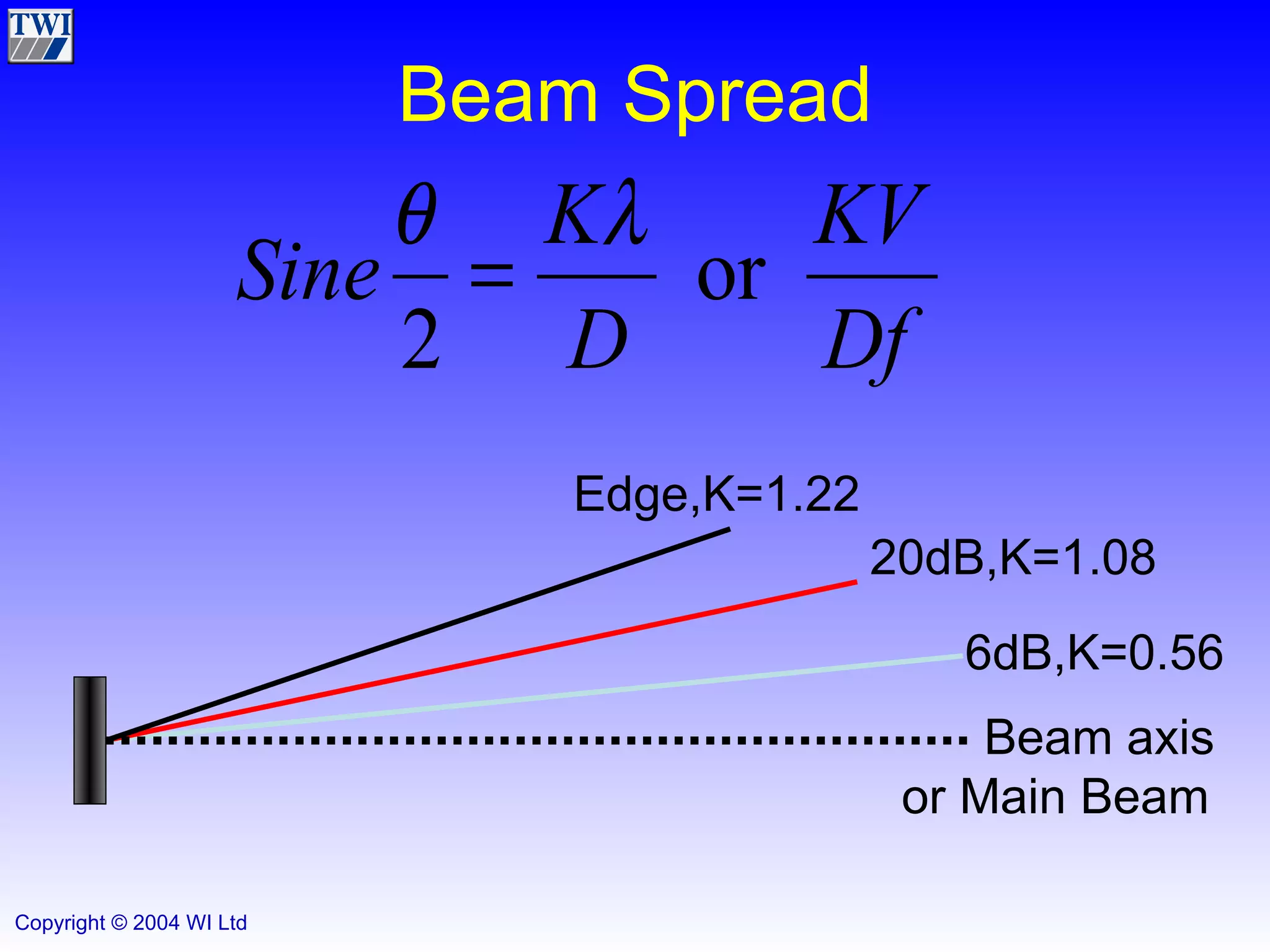

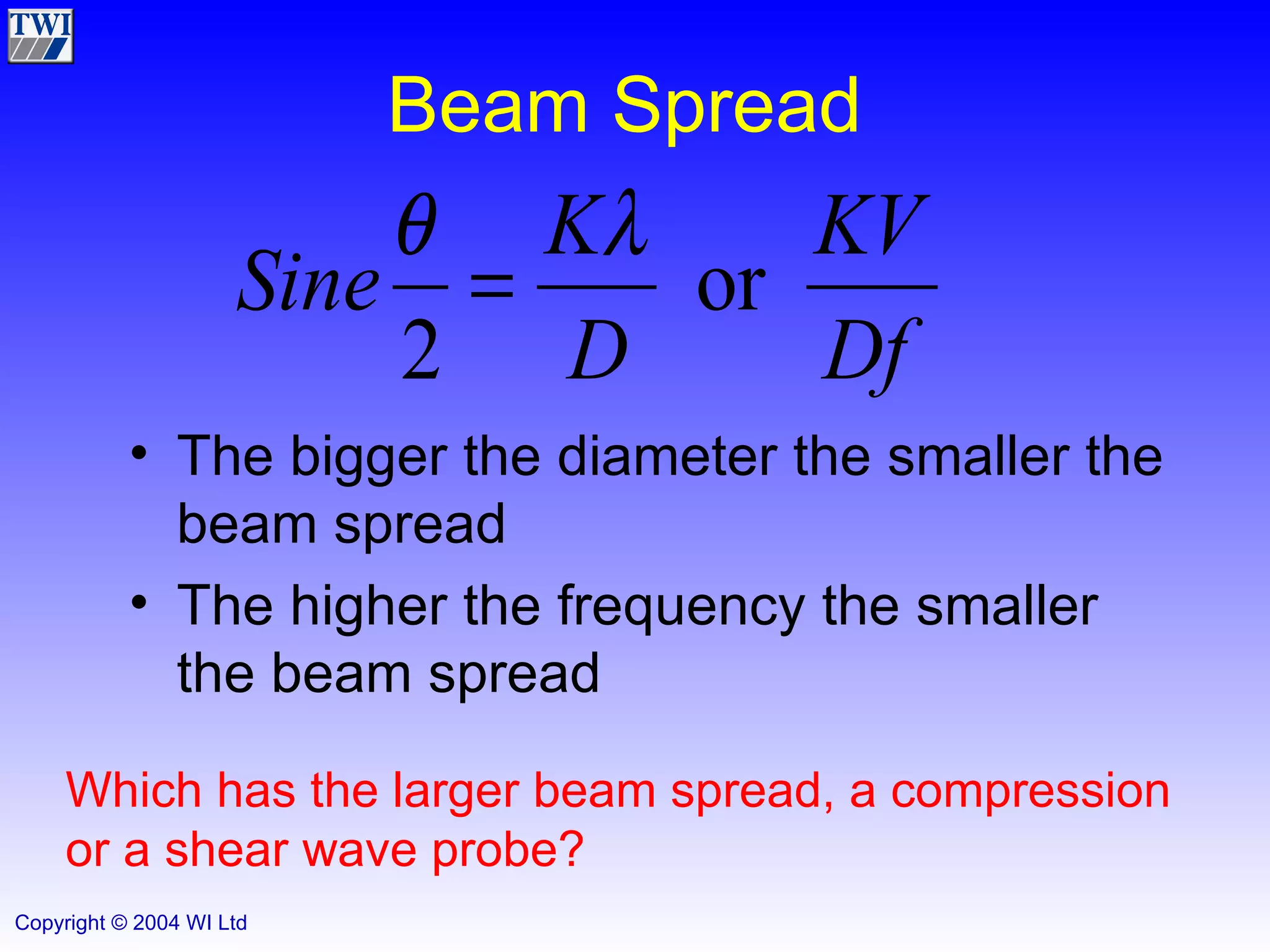

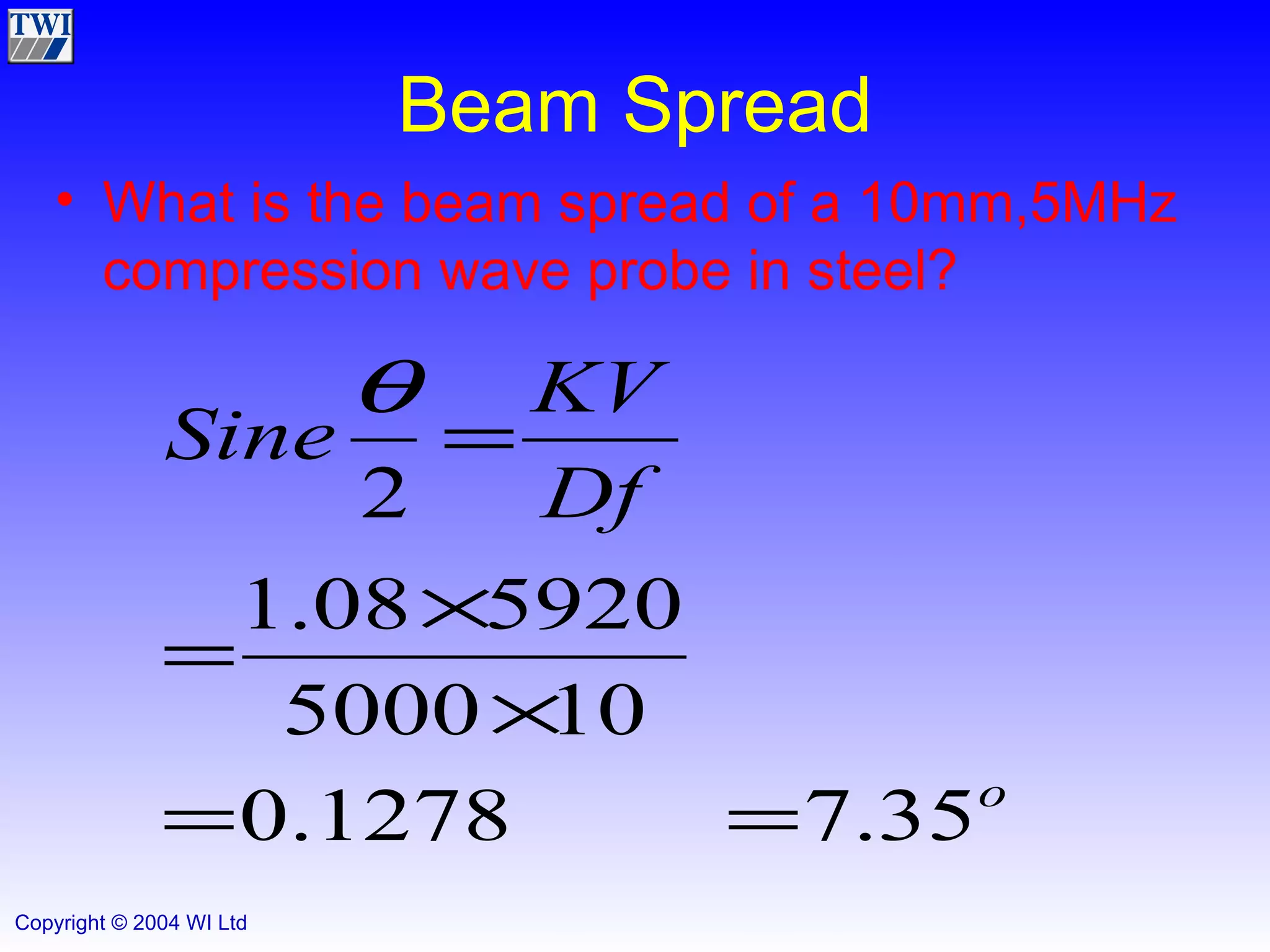

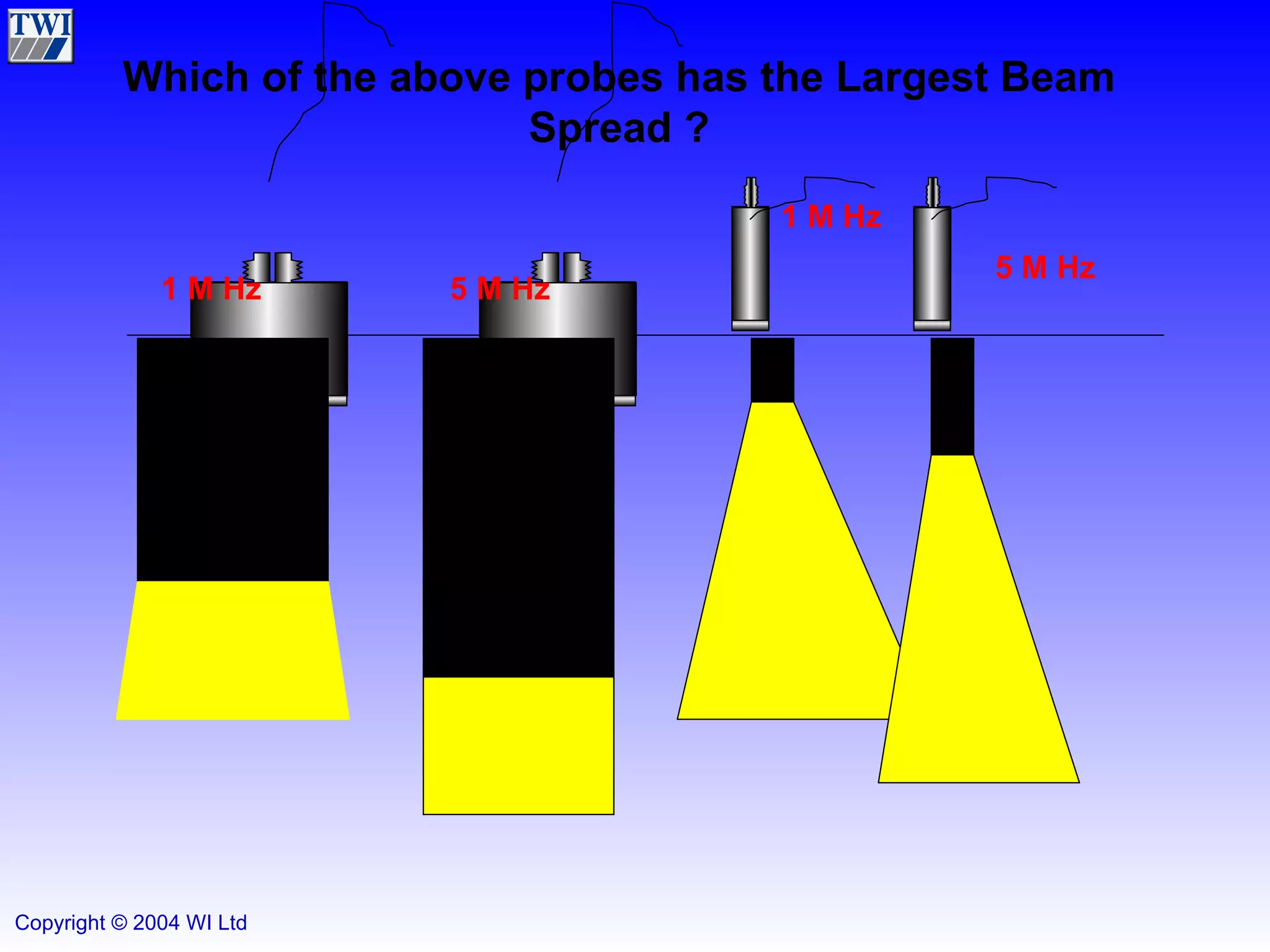

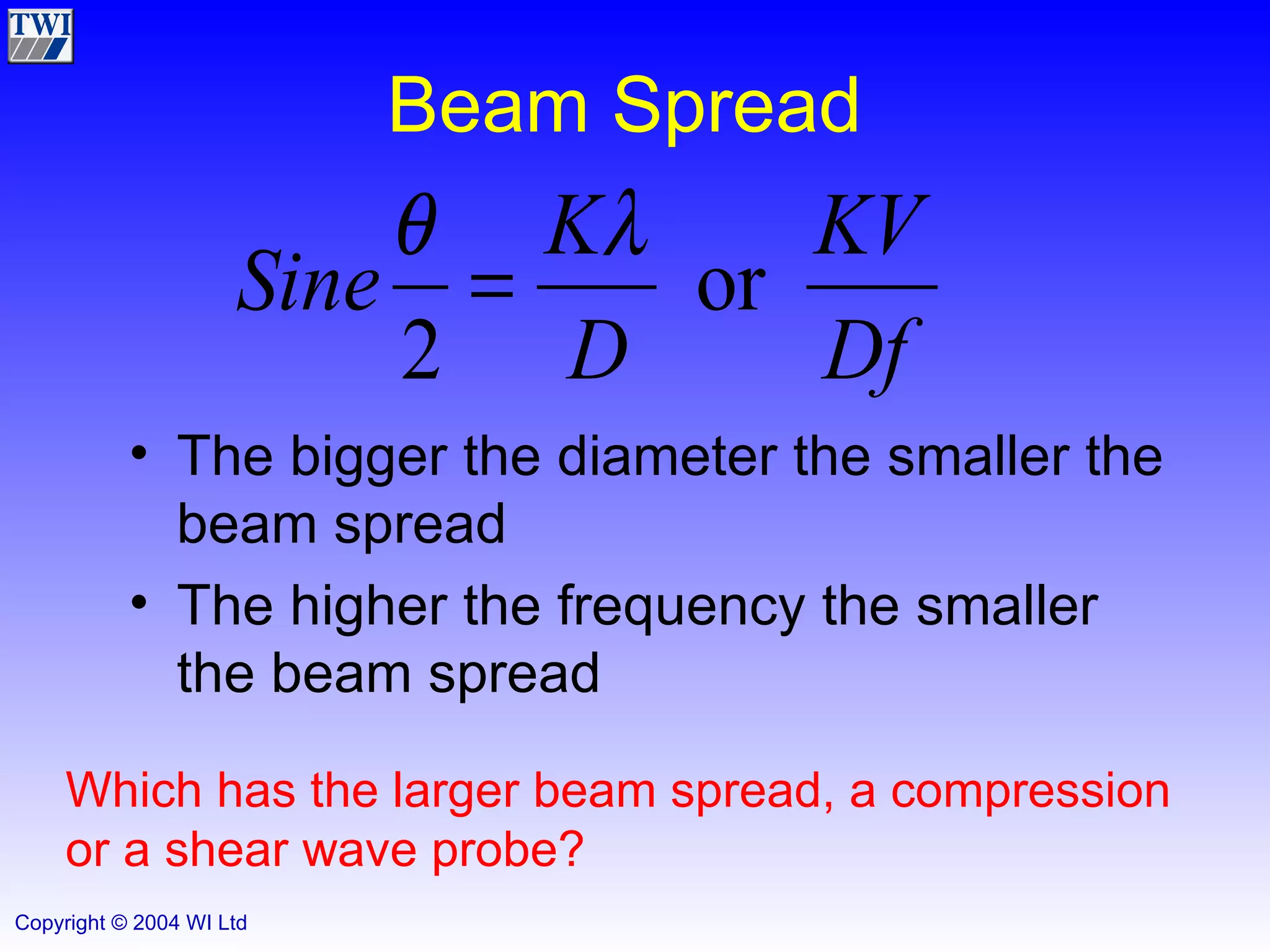

- Key concepts around sound waves, frequency, wavelength, velocity and their relationships are defined in the context of ultrasonic testing.