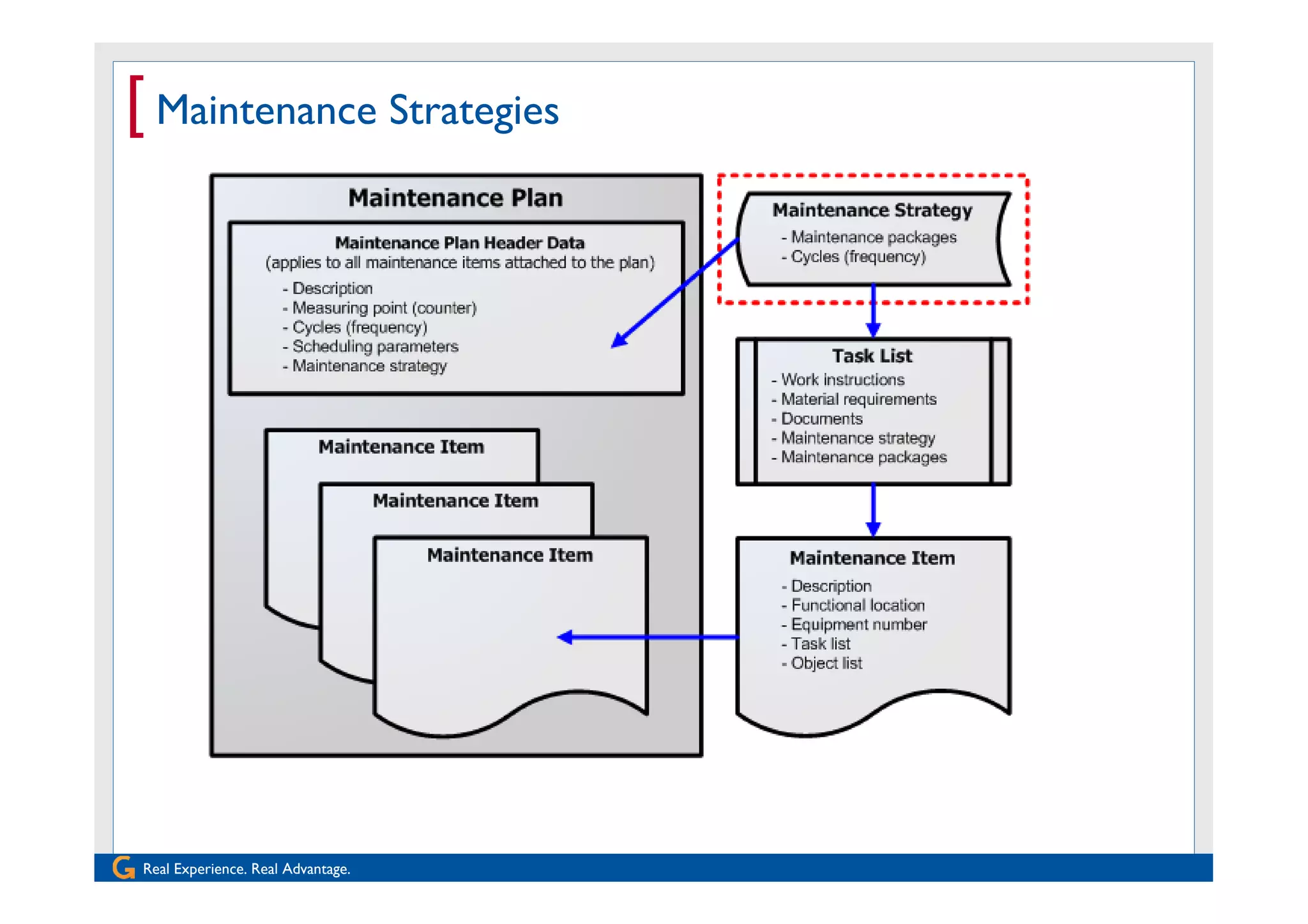

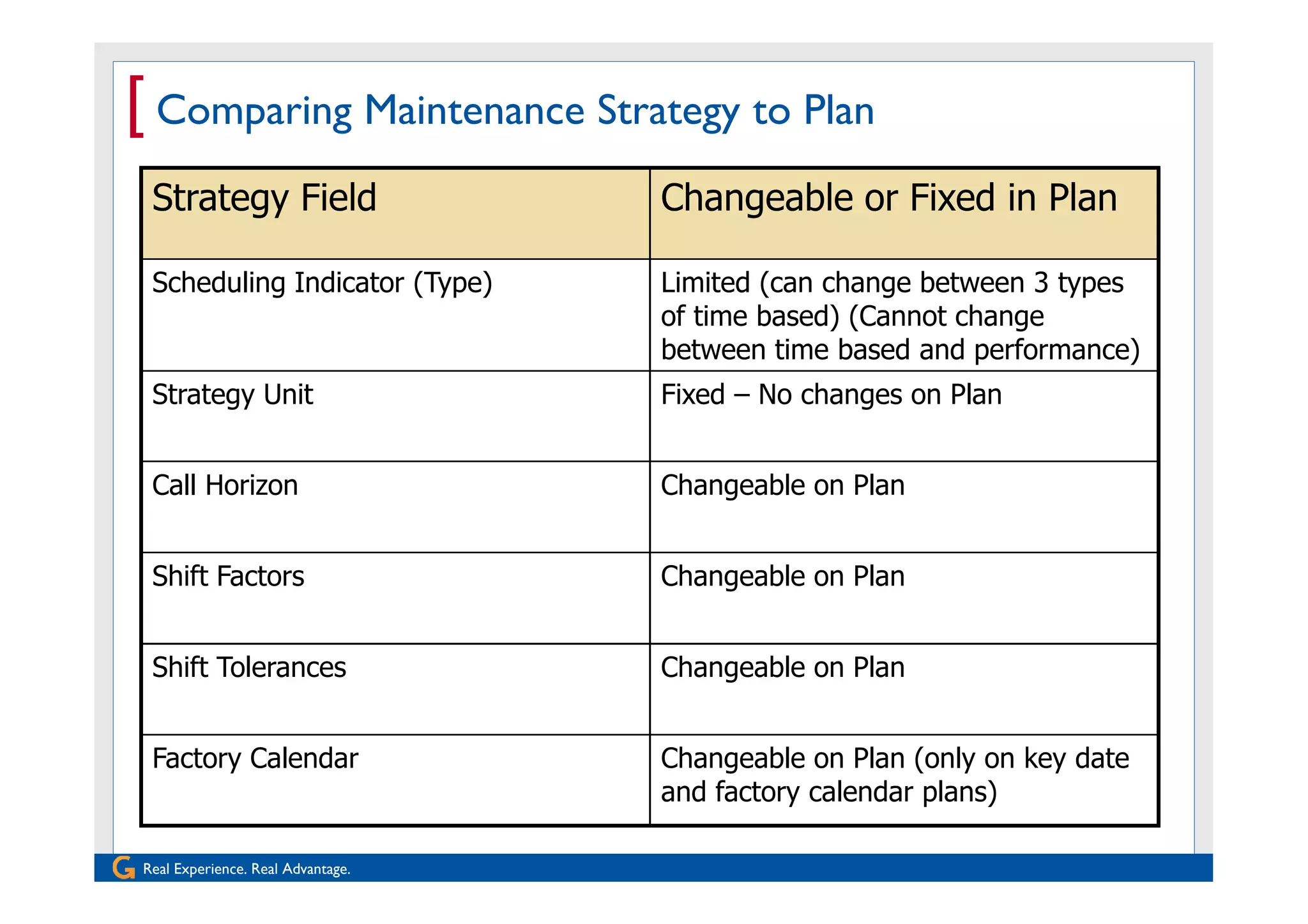

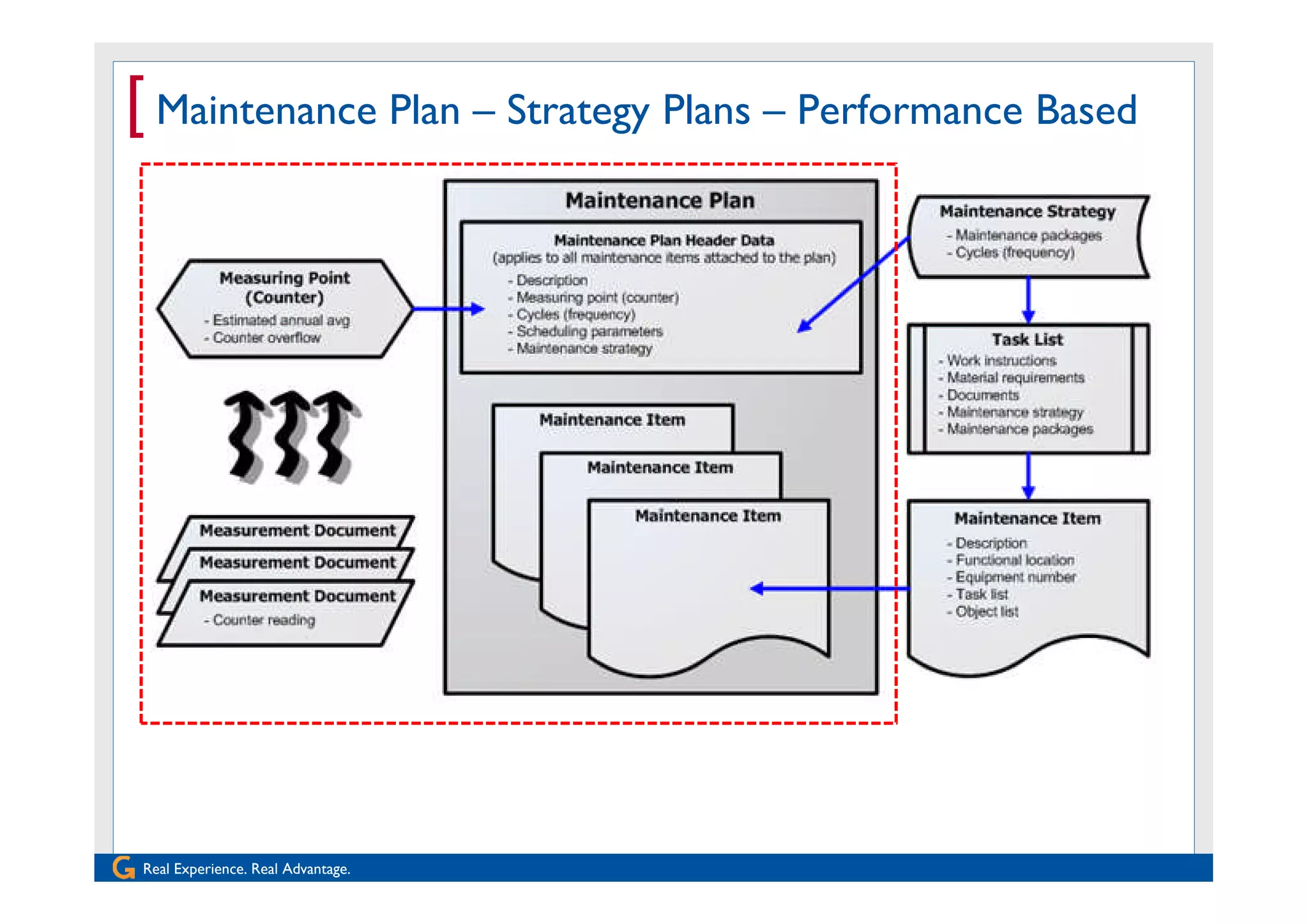

Maintenance strategy plans define the rules and frequency for maintenance activities. Strategies contain maintenance packages that define the duration or performance level at which activities are repeated. Strategies are used to build task lists and maintenance plans. Key elements of a strategy include the scheduling type, unit of measure, call horizon, shift factors, tolerances, and package hierarchy.