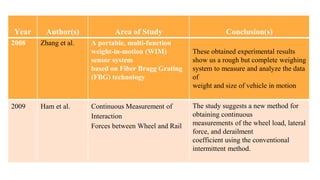

1. Fiber Bragg grating (FBG) sensors have advantages for health monitoring of bridges and railways including low cost, wavelength multiplexing capacity, and ability to measure strain and temperature.

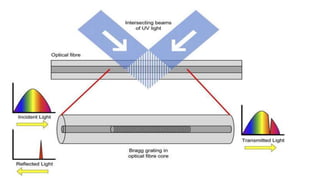

2. FBG sensors work by modulating the reflection wavelength based on the sensing element. Their periodic refractive index pattern results in a Bragg condition for specific wavelengths.

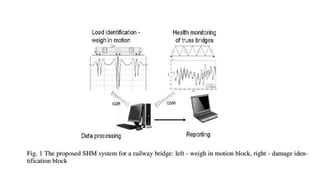

3. Applications of FBG sensors include weight measurement of trains, monitoring strength of bridges, avoiding derailment, and health monitoring of bridges and railways.