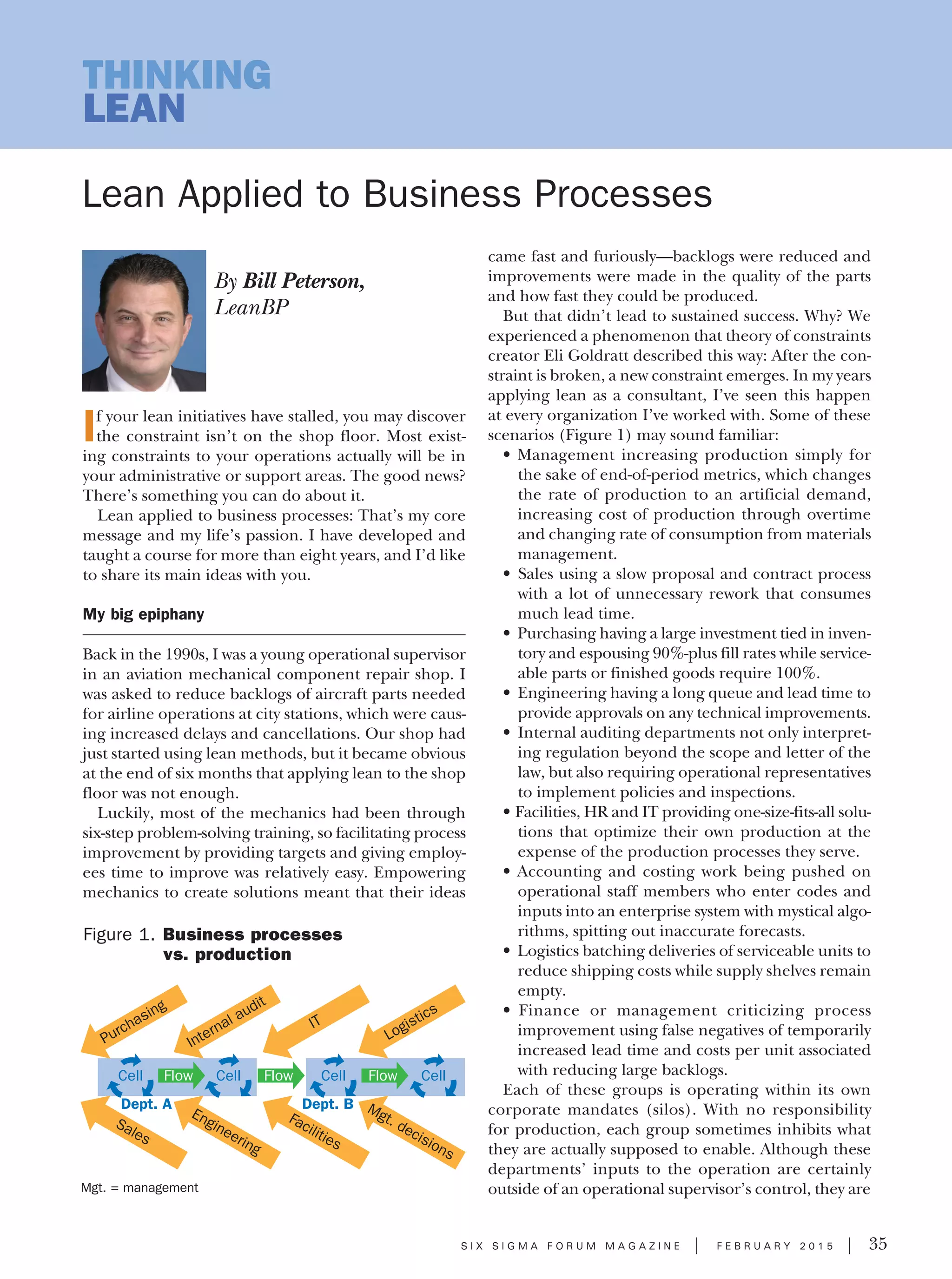

The document discusses applying lean principles to business processes and administrative functions, not just manufacturing operations. It provides an overview of common constraints that arise from support areas like sales, purchasing, engineering, and accounting. These constraints can inhibit improvements achieved on the shop floor. The author advocates using tools like strategic alignment, process mapping, and value stream analysis to identify waste and constraints in business processes. Addressing these administrative constraints through techniques like standard work and visual management can help sustain lean initiatives and further reduce bottlenecks to operations.