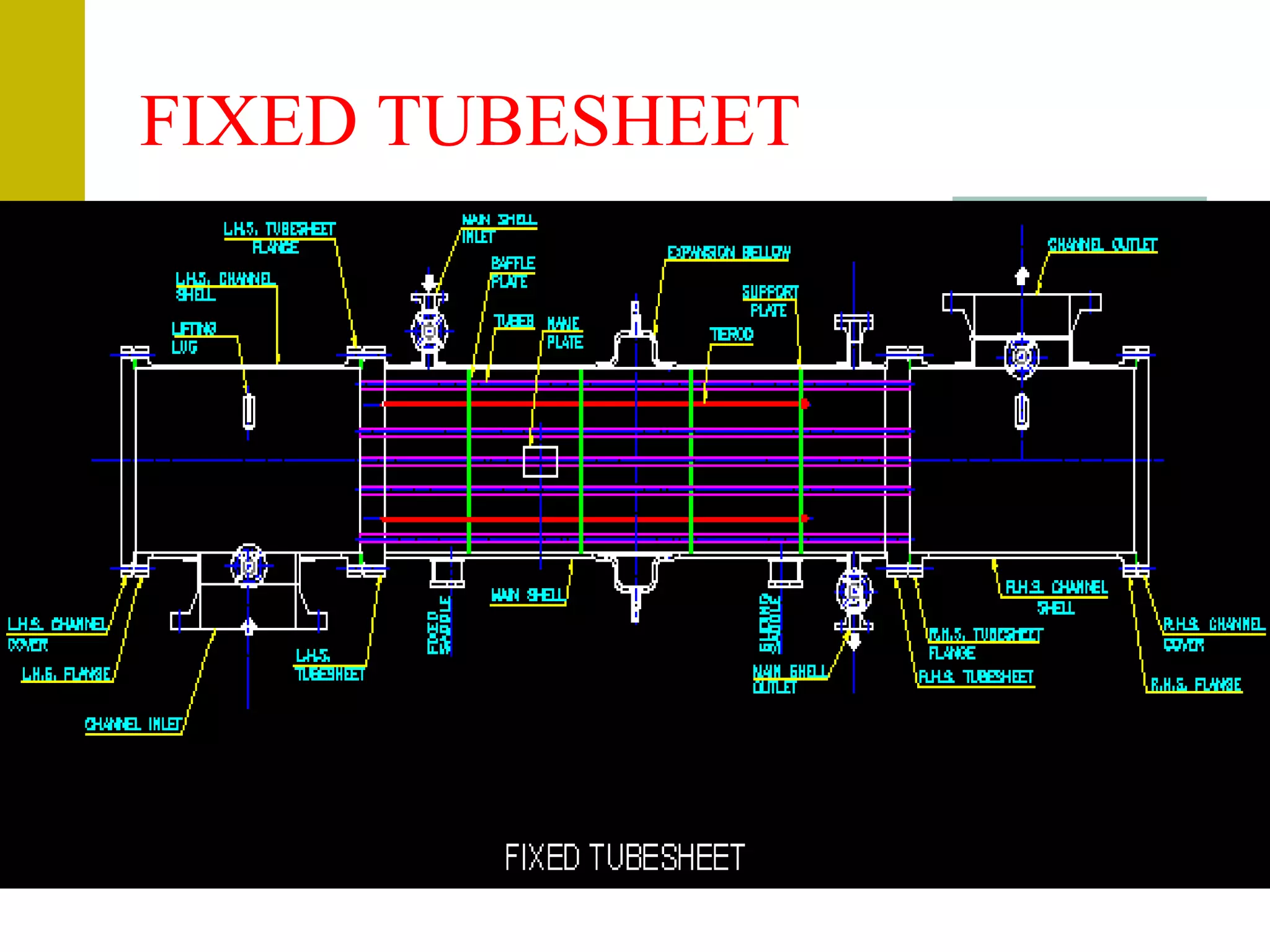

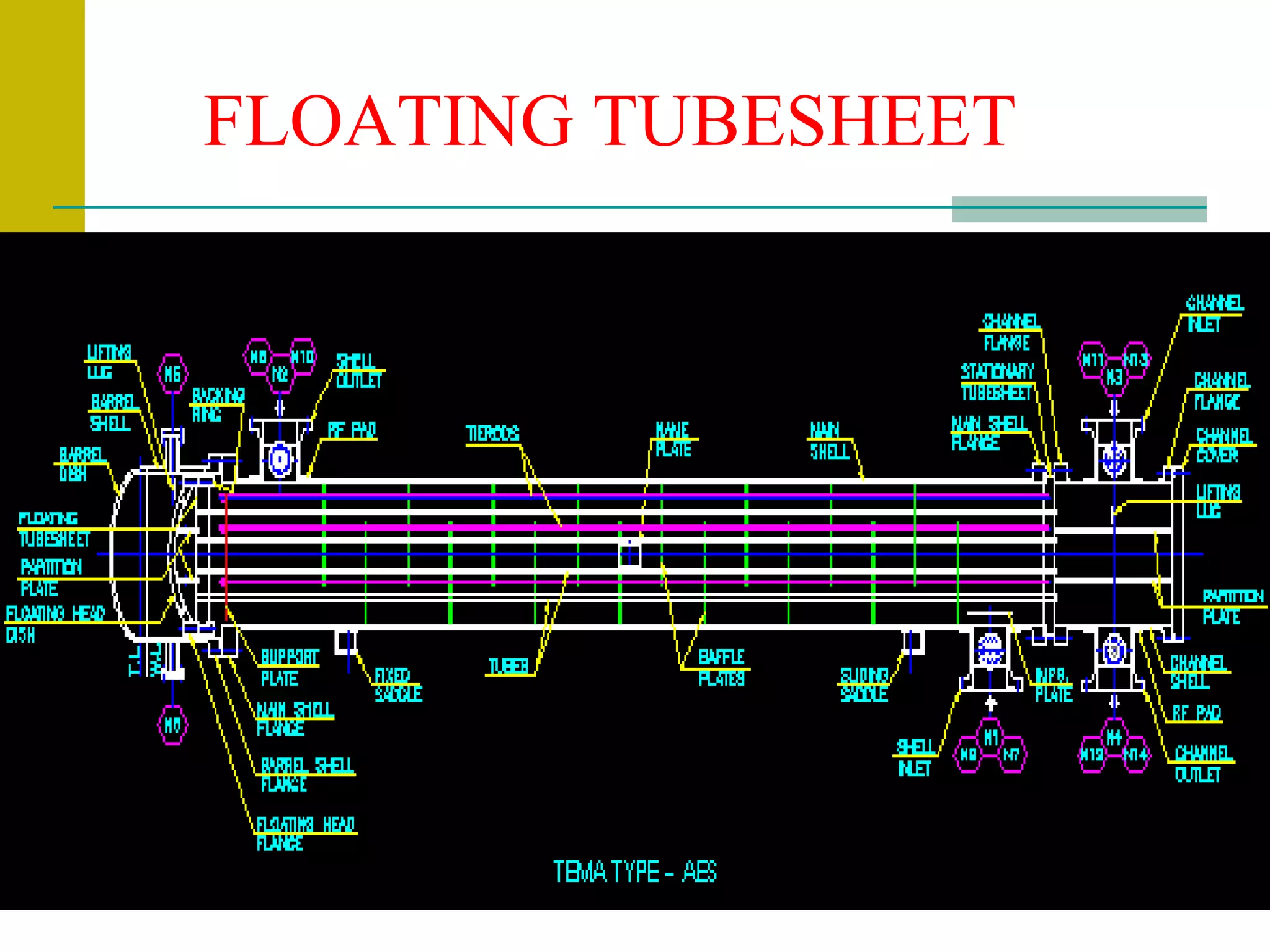

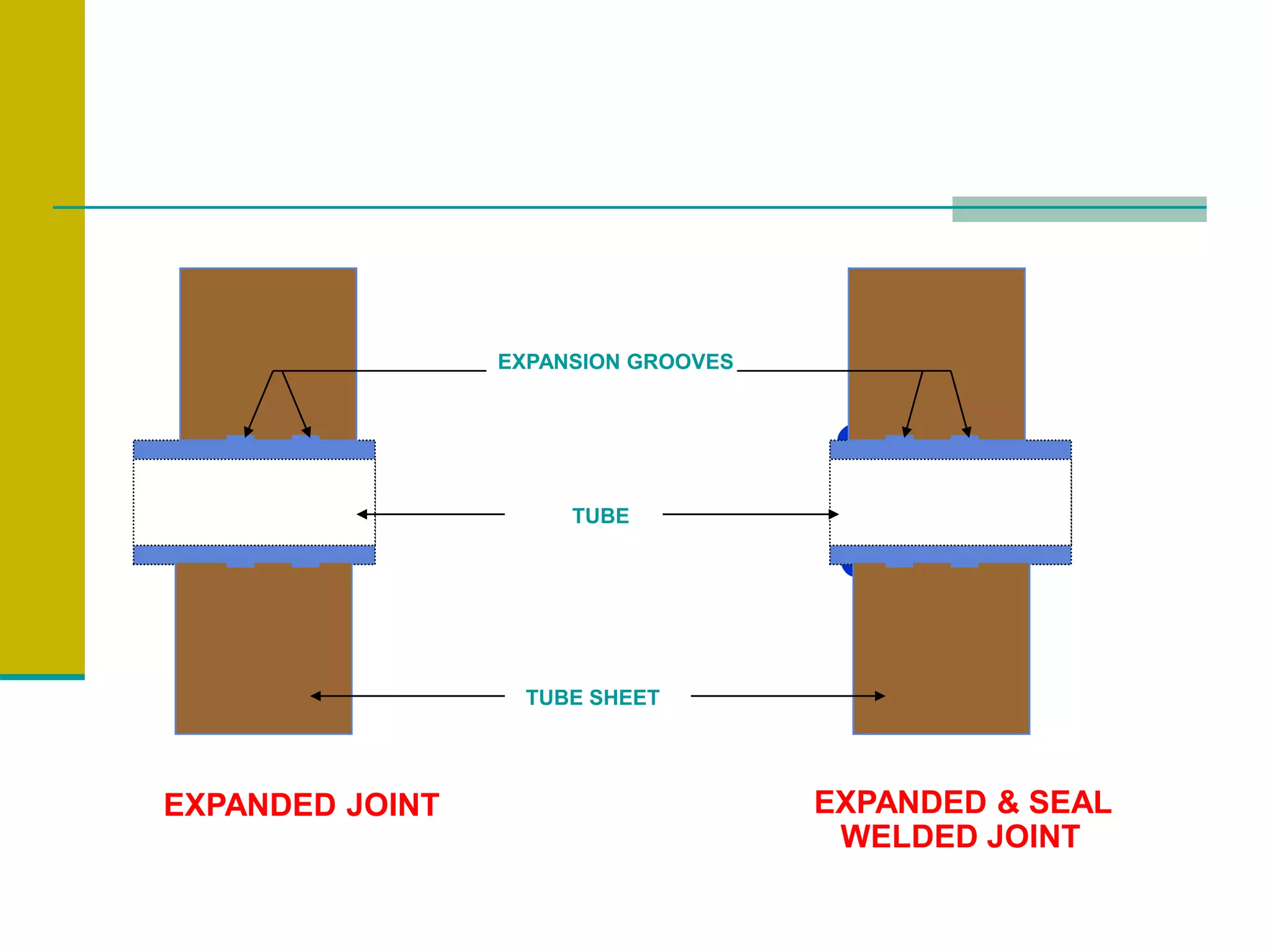

This document provides information on heat exchangers and shell and tube heat exchangers. It defines a heat exchanger as a device that transfers heat between two fluids separated by a solid wall. It describes three common types of shell and tube heat exchangers: fixed tube sheet, floating tube sheet, and "U" bundle with single tube sheet. It provides details on their construction, how they allow for differential expansion between the tubes and shell, and prevent stresses. It also discusses baffles, tube to tube sheet welding procedures and qualifications, welding processes, and leak testing.