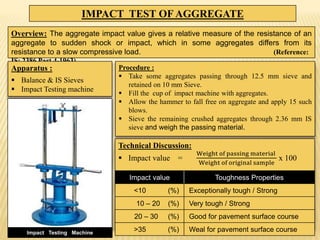

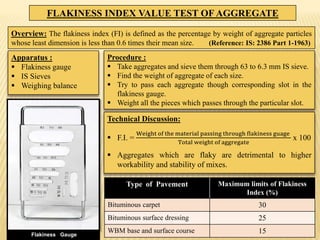

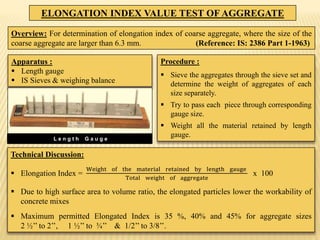

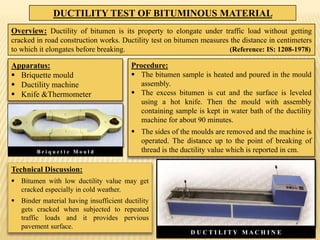

The document discusses several tests conducted on aggregates and bitumen used in road construction. It provides overview, apparatus, procedure and technical discussion for each test. The aggregate tests covered are impact value, crushing value, flakiness index, elongation index and abrasion value. The bitumen tests covered are penetration value, ductility, flash and fire point. The tests help evaluate properties like strength, toughness, shape, hardness and temperature susceptibility of materials used in pavements.