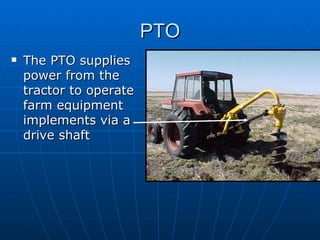

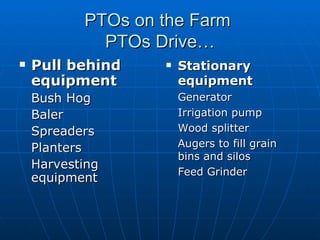

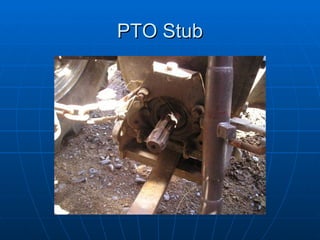

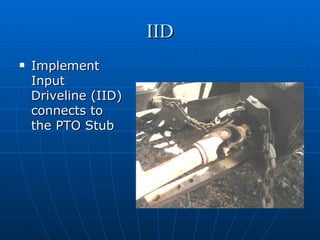

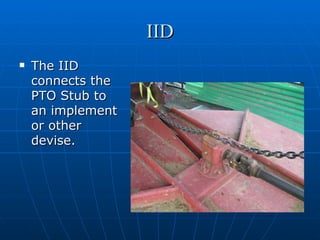

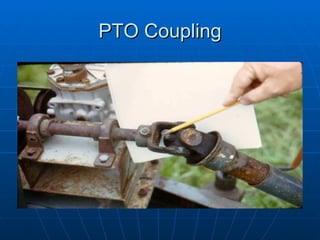

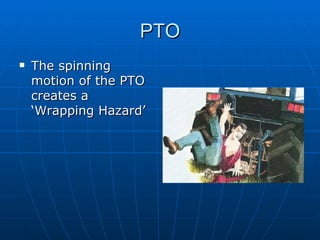

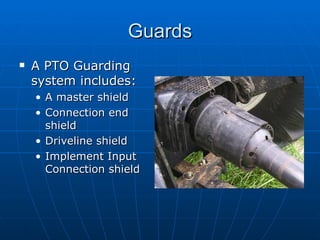

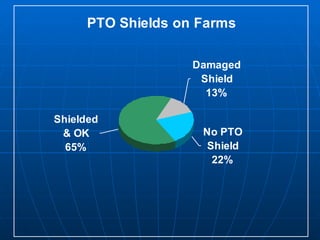

This document summarizes information about power take-off (PTO) systems on tractors and the hazards associated with them. It notes that PTOs transfer power from tractors to farm implements like augers, spreaders, and mowers. The document then discusses how PTOs operate at high speeds and can be dangerous if not properly shielded. It provides statistics showing that most PTO incidents involve stationary equipment and occur when the PTO is left engaged without the equipment moving.