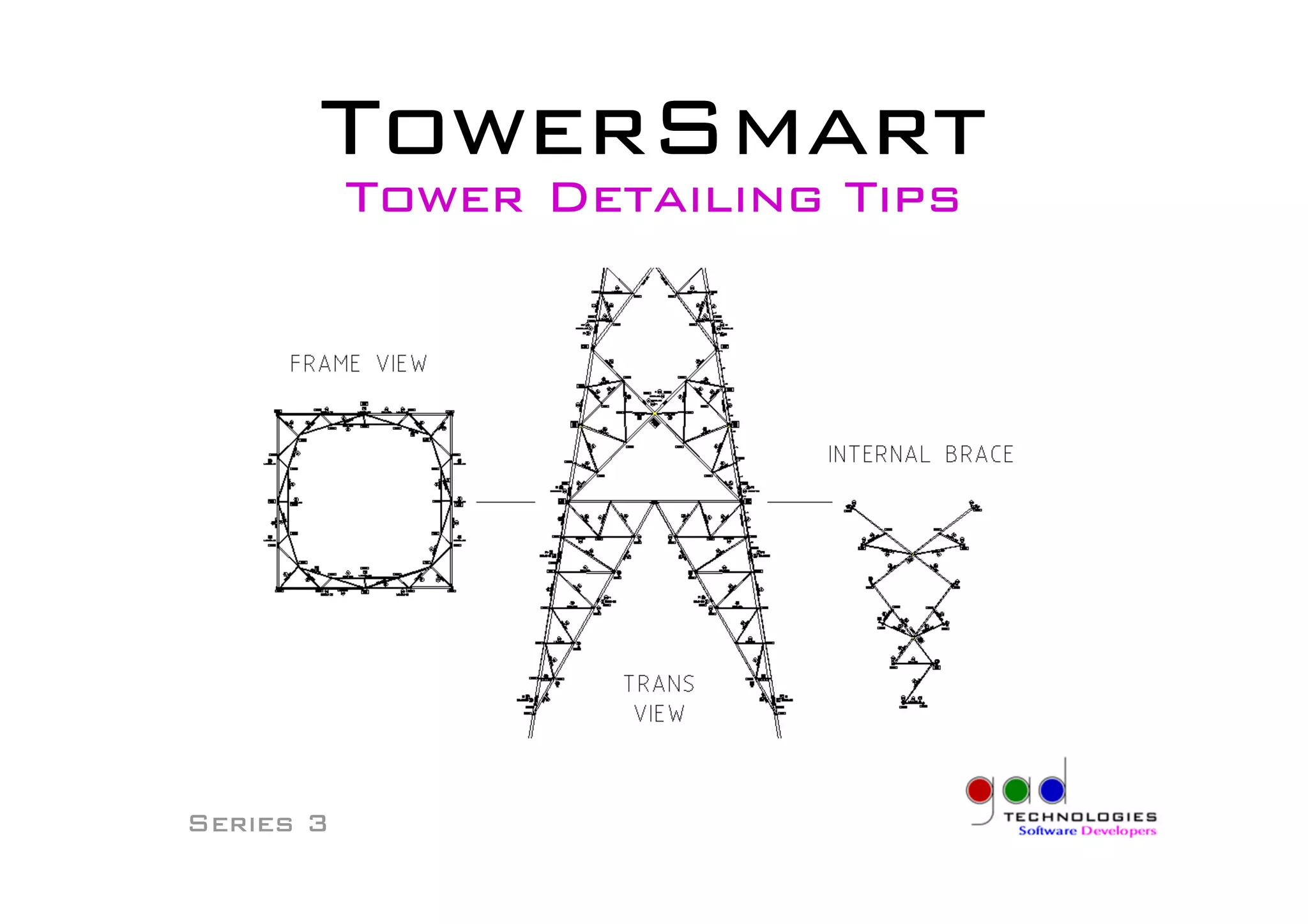

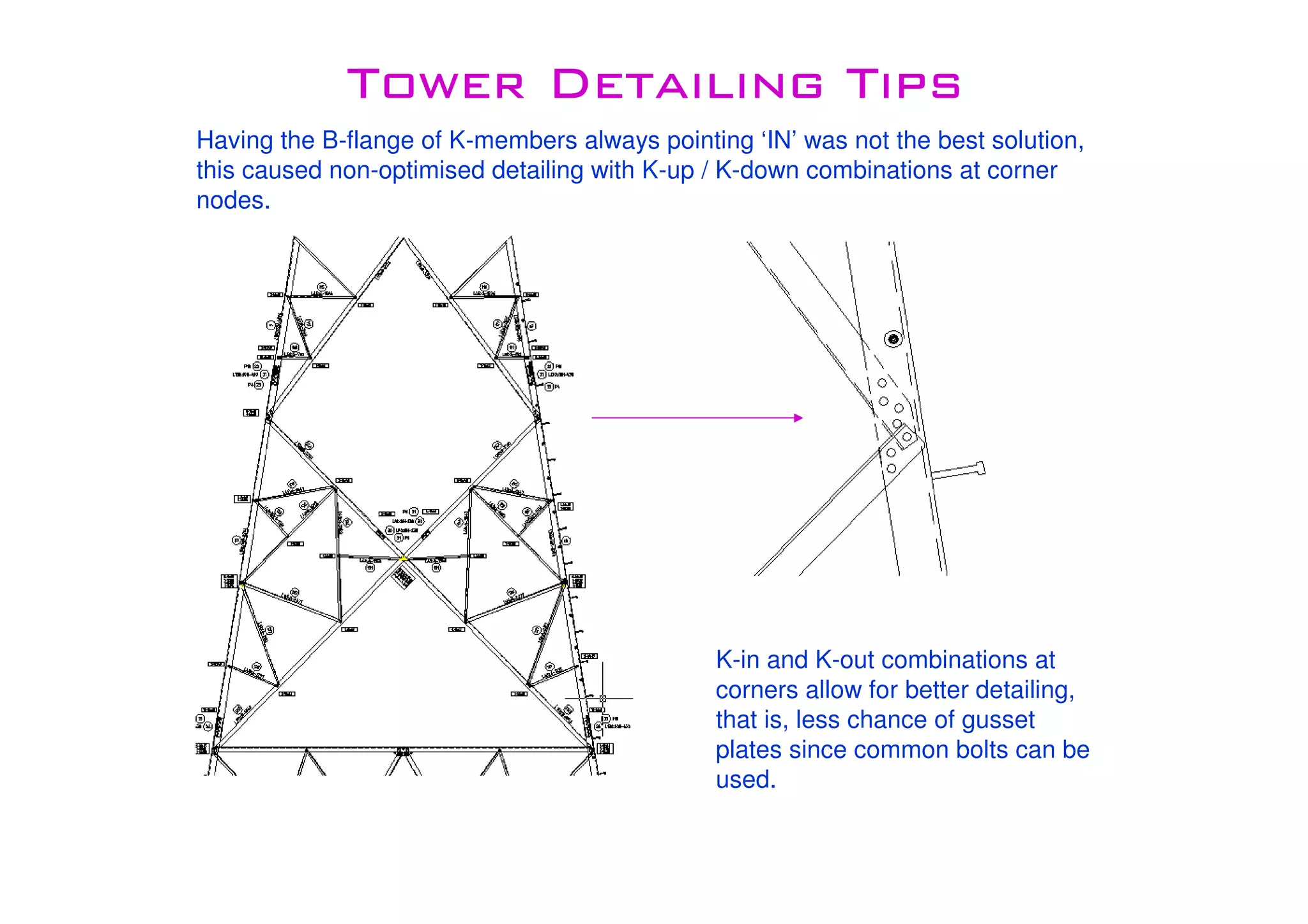

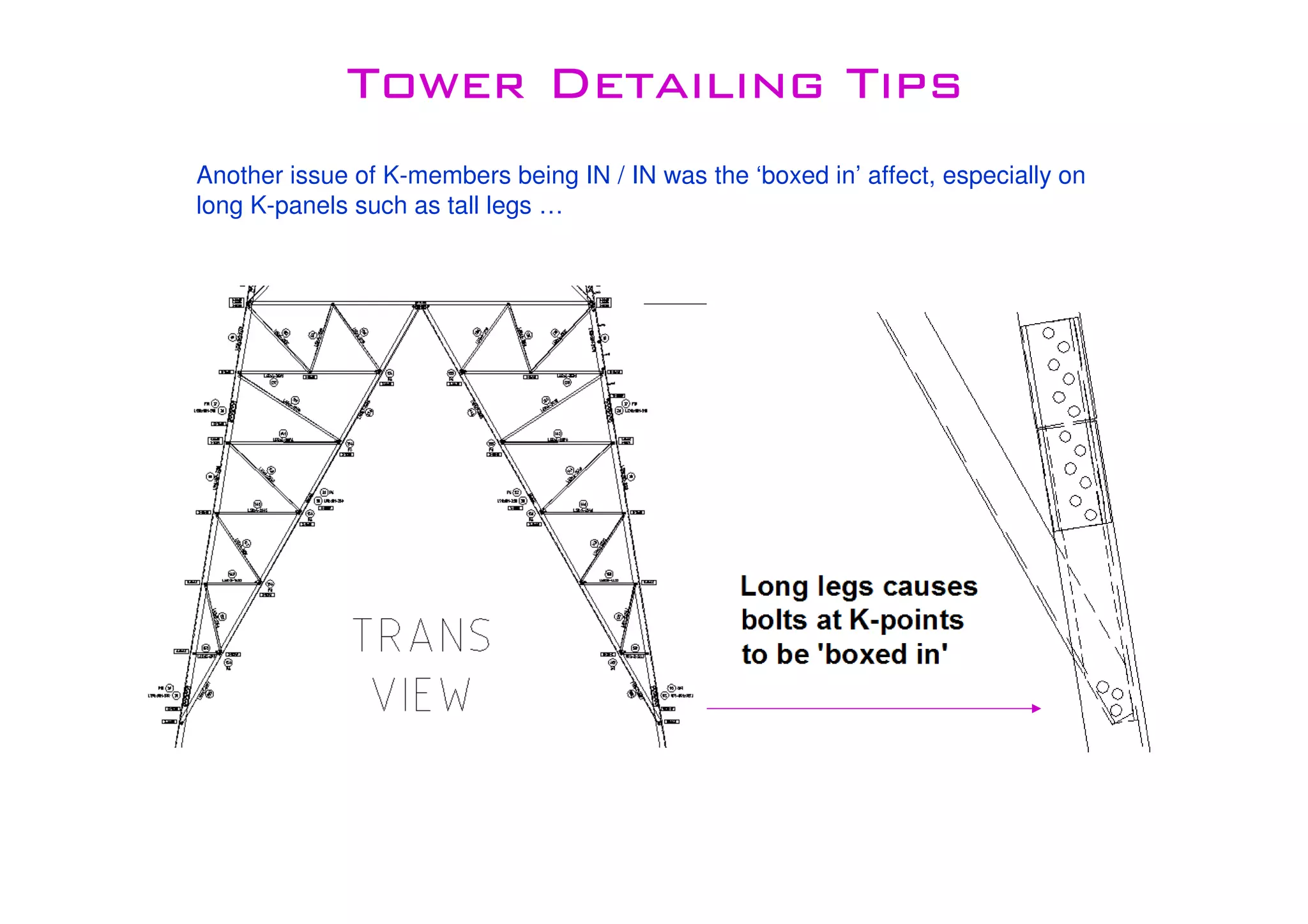

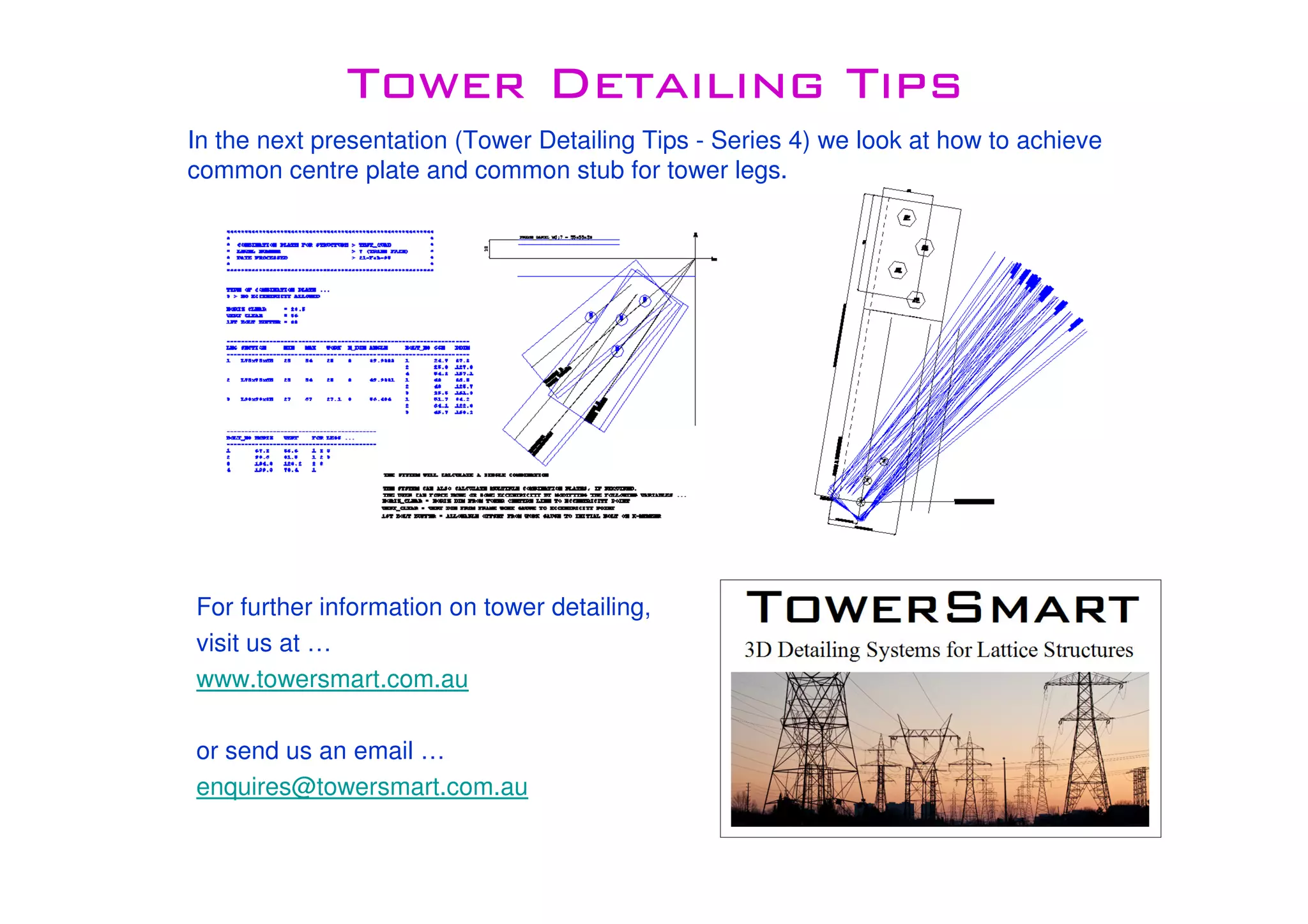

The document discusses advancements in tower detailing methods, particularly the connection of hip bracing to the a-flange of k-members as opposed to the traditional b-flange connection, which leads to better detailing and fewer complications. The a-flange connection method was found to reduce eccentricities and the number of bolts required, proving superior in various tests and leading to its adoption in transmission line and radio towers. Future presentations will cover additional aspects of tower detailing.