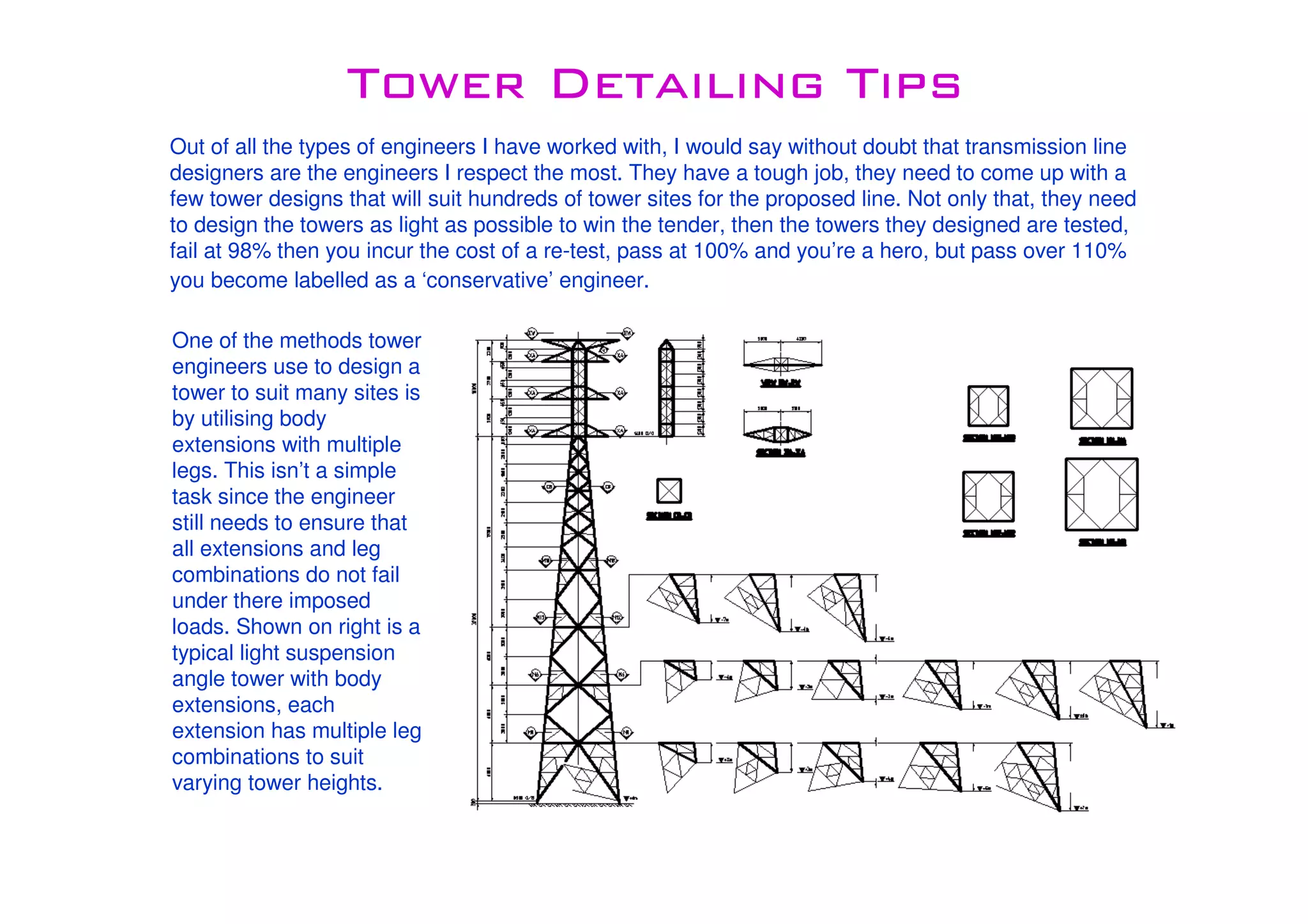

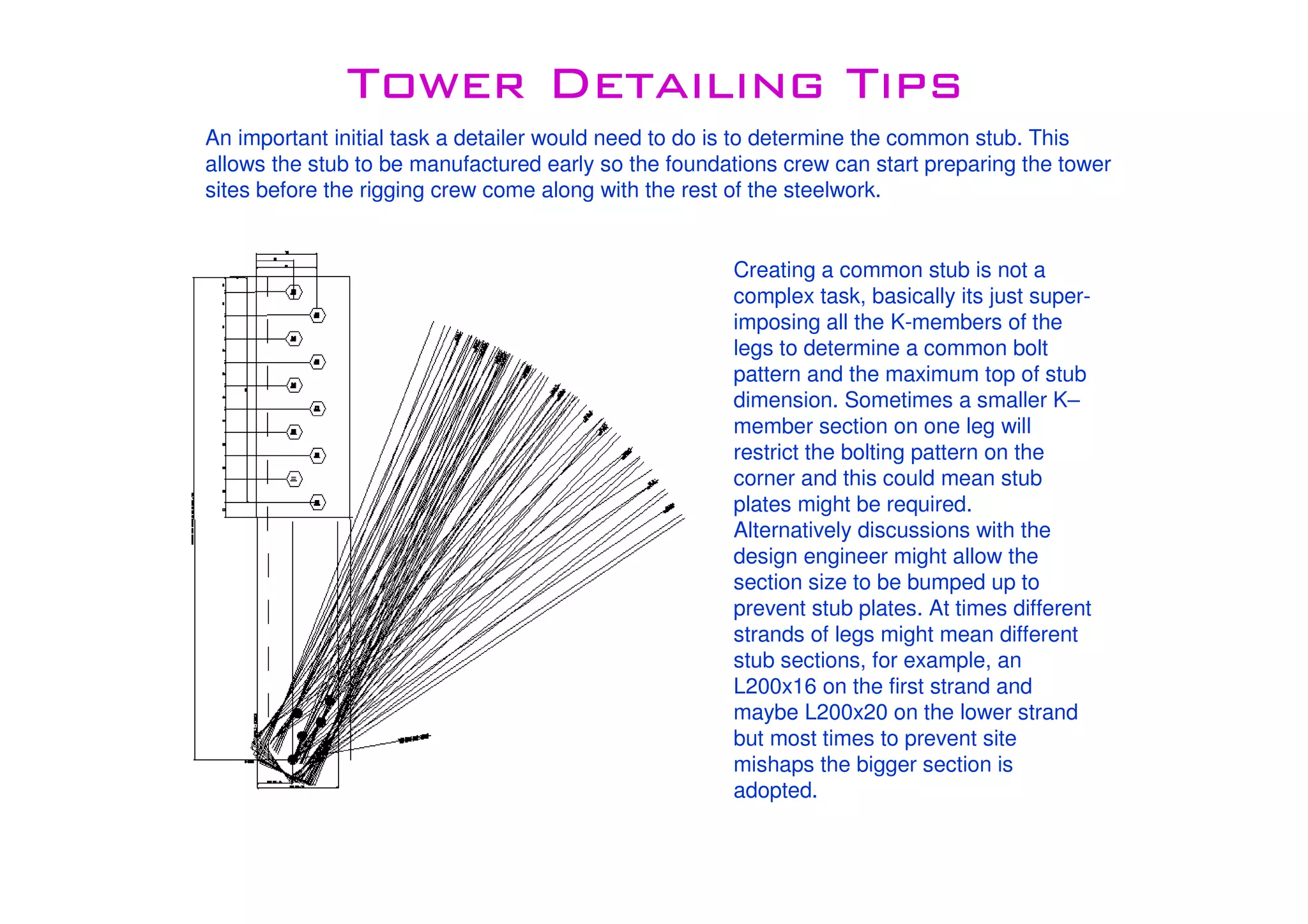

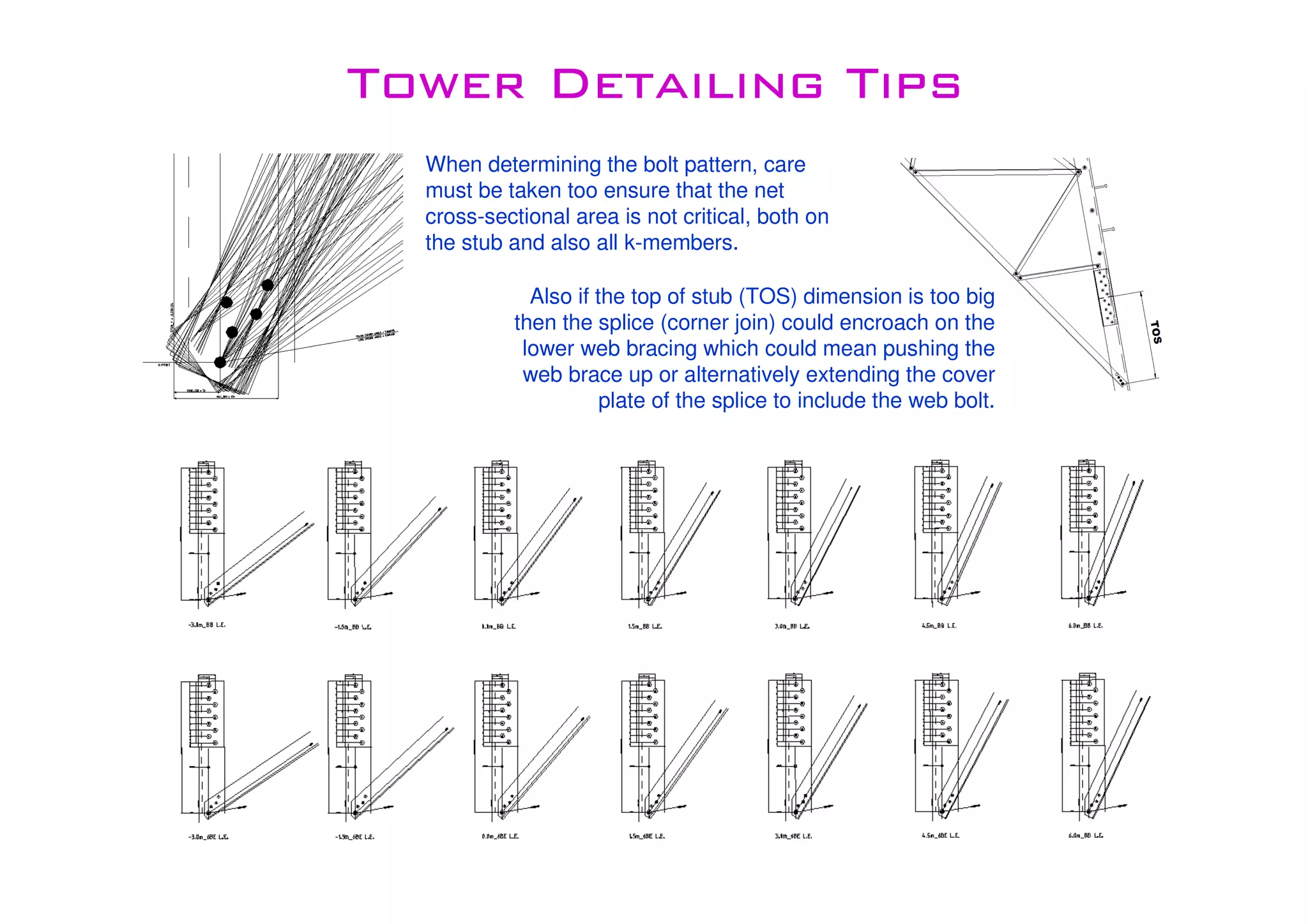

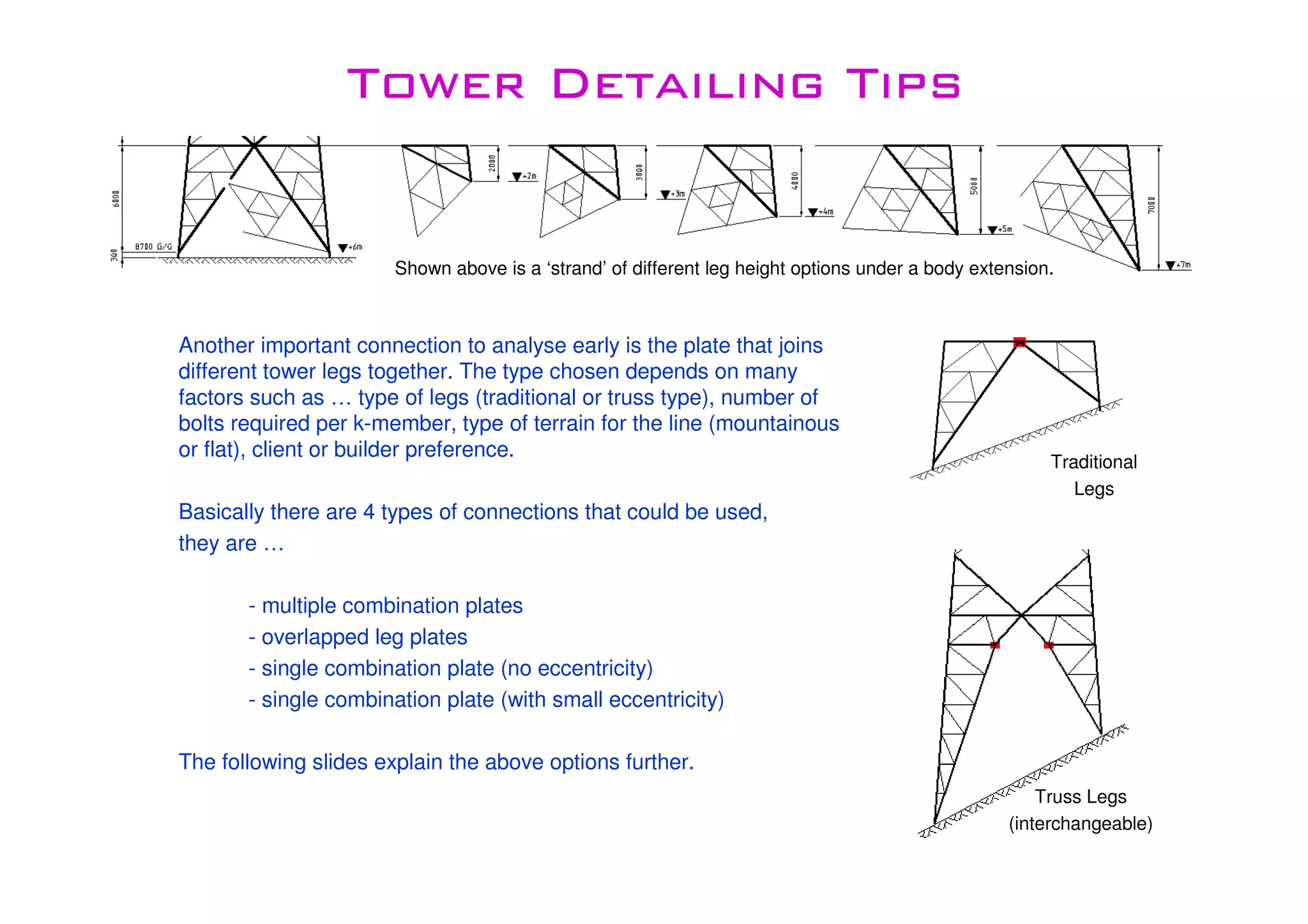

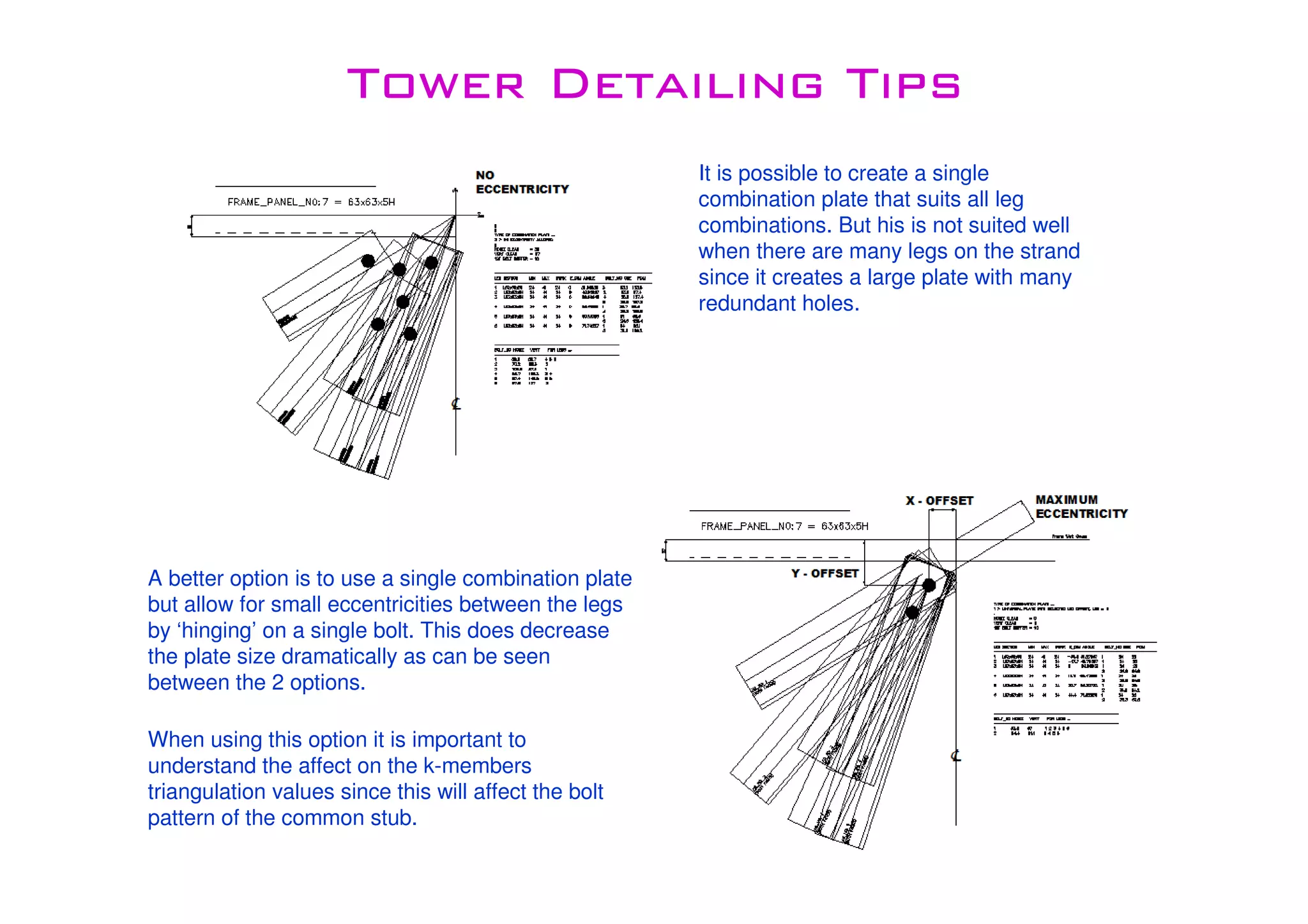

Transmission line tower designers have a difficult job designing lightweight yet robust towers that can accommodate varying site conditions. One method they use is including body extensions with multiple leg combinations to suit different tower heights. An important initial task for detailers is determining a common tower stub to allow early foundation work, which involves superimposing leg profiles to find a common bolt pattern. The type of connection joining different tower legs depends on factors like leg type and terrain, with options including multiple plates for each combination, overlapped plates, or single plates with or without small eccentricities between legs.