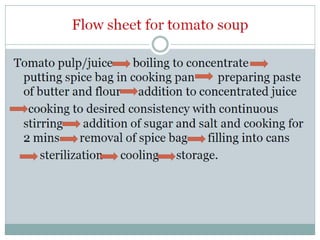

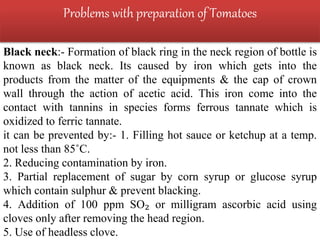

This document discusses processed tomato products including tomato juice, puree, paste, sauce, ketchup, chutney, and soup. It provides recipes and instructions for producing each product. Key points include:

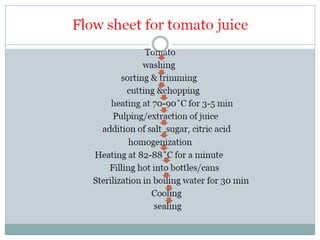

- Tomato juice should be deep red, have characteristic tomato taste and flavor, and contain specified levels of acid, salt, and sugar. Hot pulping is superior to cold pulping.

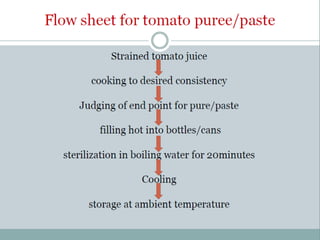

- Puree and paste are concentrated tomato pulp that contain a minimum percentage of tomato solids.

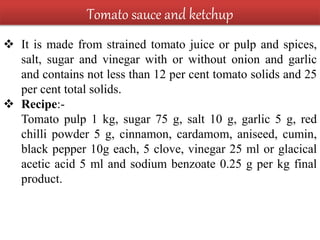

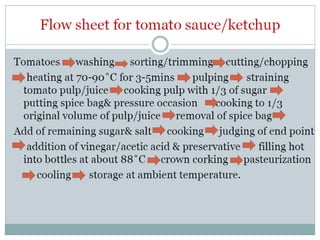

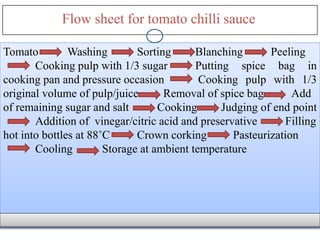

- Sauces and ketchups contain tomato pulp, spices, salt, sugar, and vinegar. Recipes for each are provided.

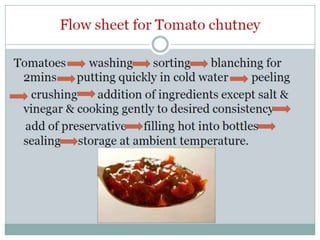

- Chutney must contain a minimum percentage of fruit and have a smooth, perishable