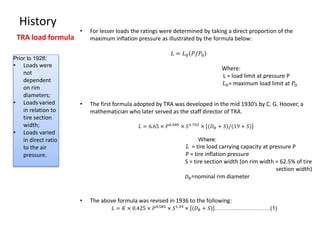

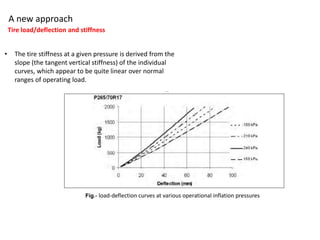

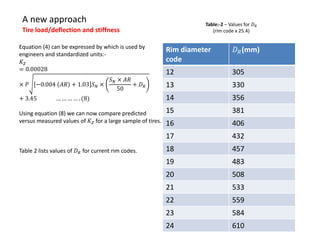

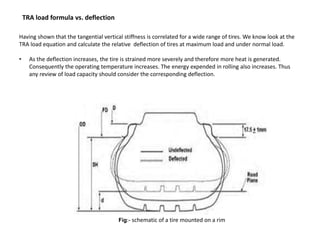

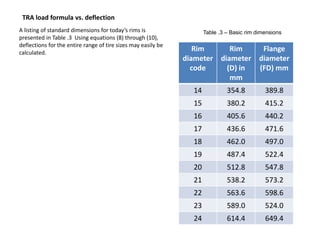

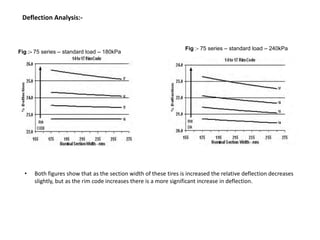

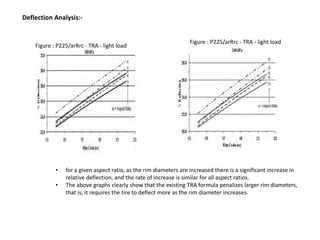

The document details the evolution of the Tire and Rim Association (TRA) load formula for passenger car tires, outlining its historical adjustments and the relationship between tire load, deflection, and stiffness. It introduces a new approach that correlates tire stiffness with inflation pressure, footprint width, and outside diameter, presenting various equations for evaluating these parameters. Additionally, it discusses the implications of deflection on tire durability and includes tables of standard dimensions for rim codes and tire sizes.

![From equation (9), for the linear case, we see that load is equal to the product of deflection and stiffness, and we

have already developed equation (8) to calculate stiffness.

Transposing equation (10) to give the deflection in terms of the nominal section width and aspect ratio results in

the following equation:

𝑑 =

%𝑑×(𝐻−17.5)

100

=

%𝑑×(

𝑆𝑁×𝐴𝑅

100

−17.5)

100

……………..(11)

From equation (8) and (11)-

𝐿

=

%𝑑 × (

𝑆𝑁 × 𝐴𝑅

100

− 17.5)

100

× [0.00028 × 𝑃 −0.004 𝐴𝑅 + 1.03 𝑆𝑁 ×

𝑆𝑁 × 𝐴𝑅

50

+ 𝐷𝑅

+ 3.45 ] … … … … . (12)

Proposed load formula:-](https://image.slidesharecdn.com/tireloadcapacity1-230323093012-805636cc/85/TIRE-LOAD-CAPACITY-pptx-16-320.jpg)