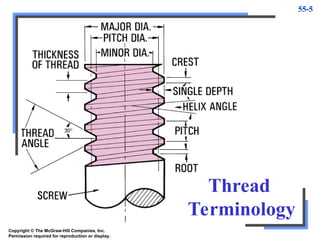

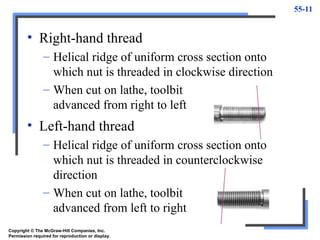

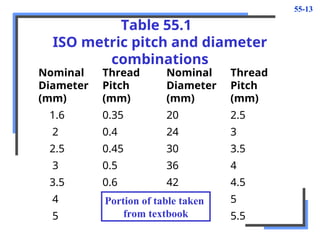

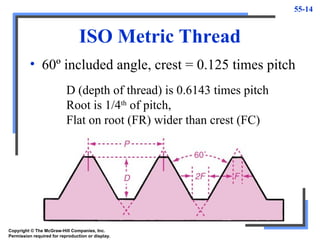

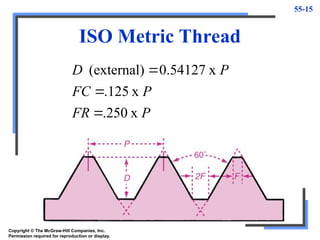

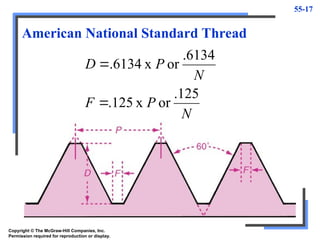

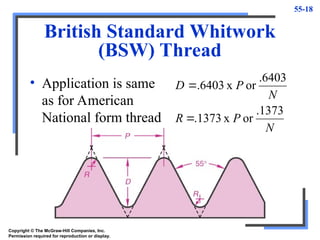

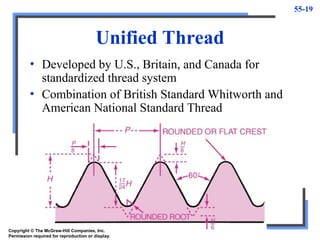

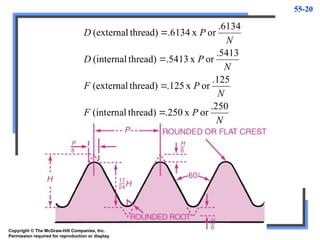

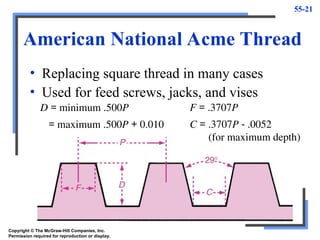

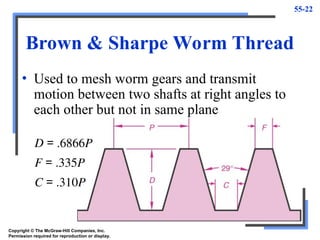

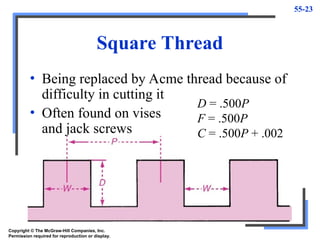

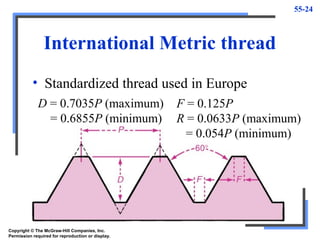

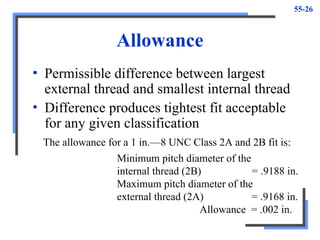

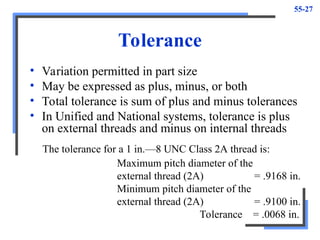

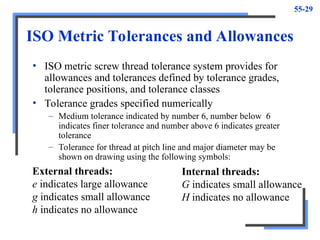

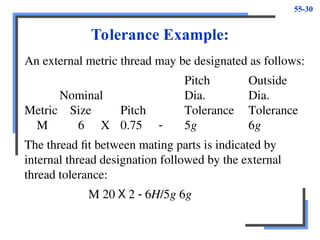

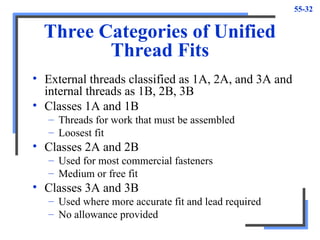

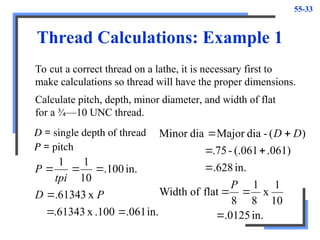

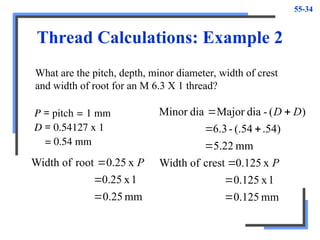

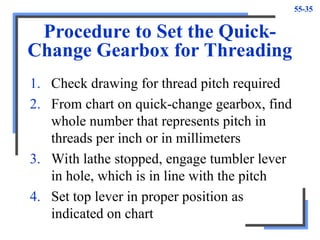

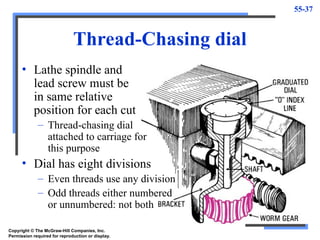

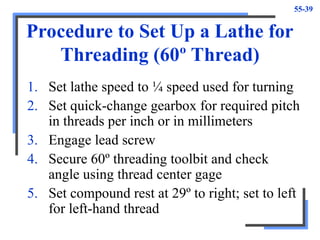

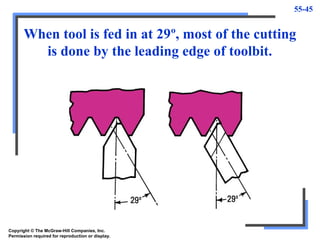

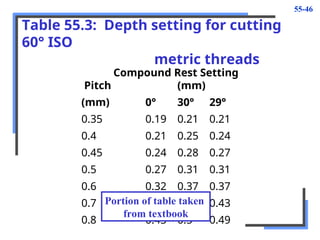

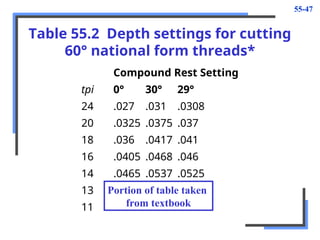

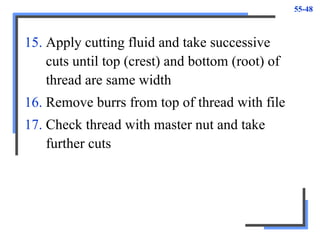

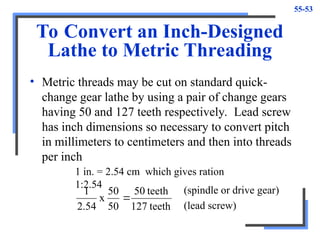

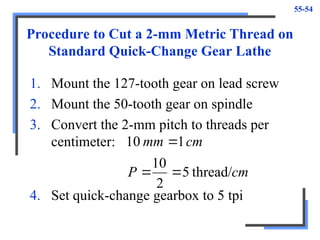

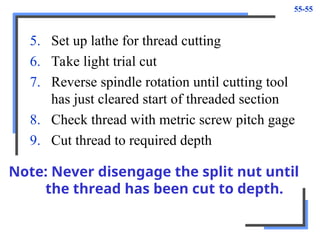

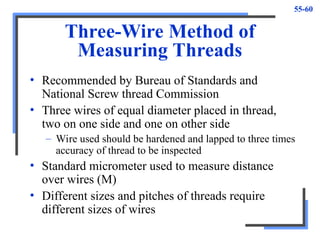

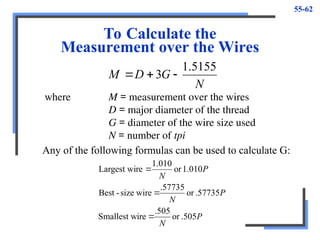

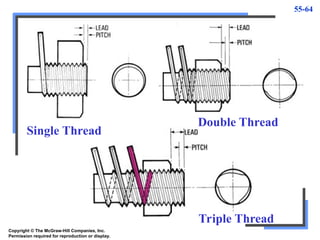

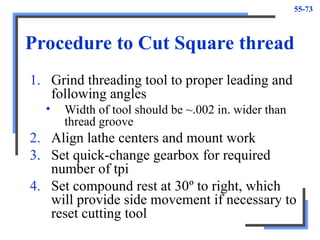

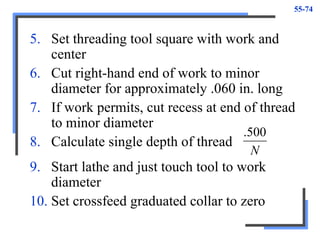

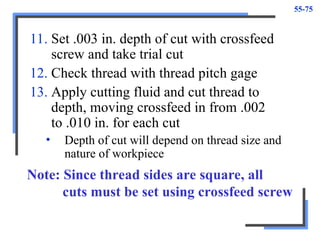

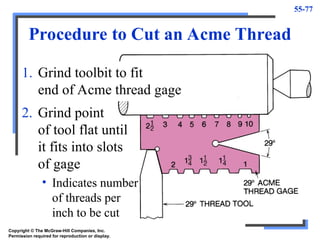

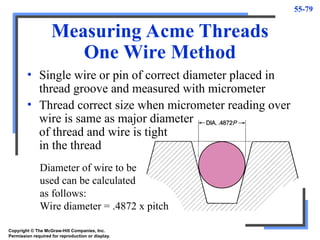

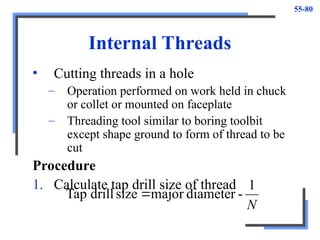

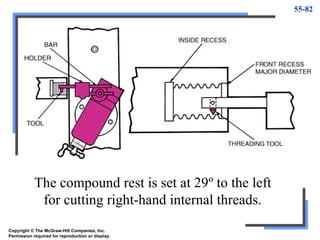

The document outlines the technologies and procedures involved in thread cutting on lathes, covering various types of threads such as external, internal, and acme threads. It details thread terminology, measurements, and the setup required for cutting both metric and unified threads, including tolerances and allowances for different thread fits. Additionally, it provides step-by-step procedures for setting up a lathe for threading operations and verifying thread accuracy.