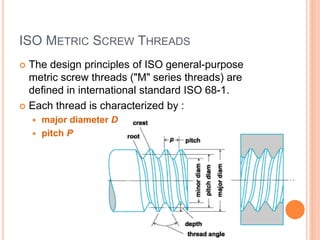

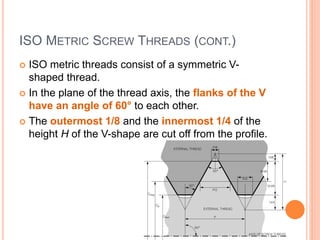

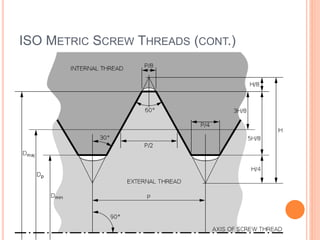

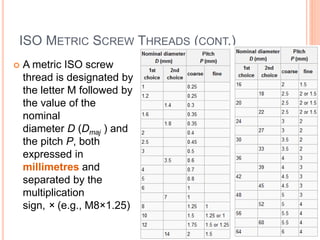

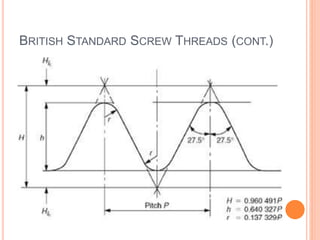

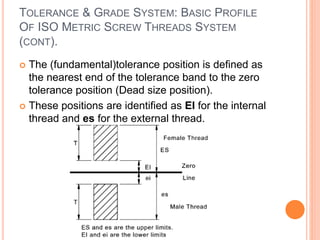

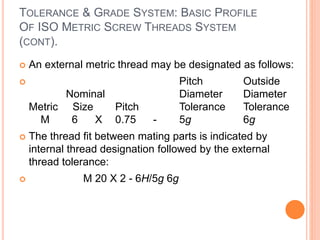

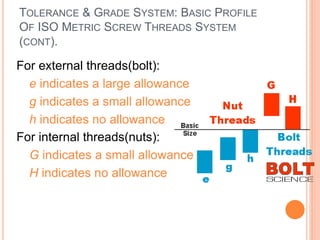

The document discusses screw thread measurement and different thread standards. It begins by defining a screw thread as a helical structure that converts rotational motion to linear motion. There are several common thread standards including ISO metric, British Standard, and Unified Thread Standard. ISO metric threads have a symmetric V-shape profile with 60 degree flanks and are designated by the letter M followed by the diameter and pitch in millimeters. Thread gauges are used to measure thread pitch and profile and classify threads. Tolerances are applied to threads using tolerance classes to ensure proper fit between external and internal threads.