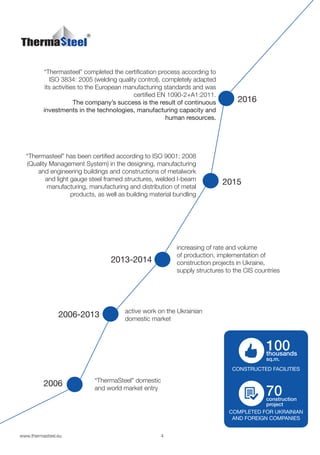

Thermasteel is a construction-engineering company specializing in metalwork and light gauge steel framed structures, with over 70 completed projects globally and certifications according to ISO standards. The company offers a wide range of services, including project design, manufacturing of roofing and facade materials, and quick erectable frame constructions, using advanced technology and high-quality raw materials. With a workforce of over 170 professionals and facilities exceeding 10,000 sq. m, Thermasteel emphasizes reliability, rapid expansion, and compliance with international standards.