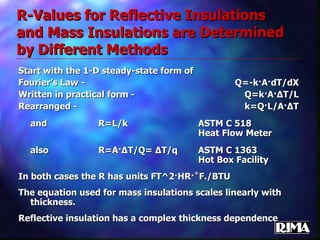

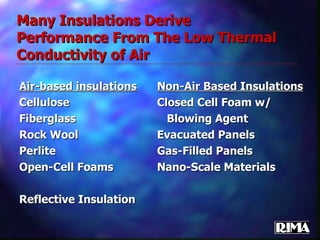

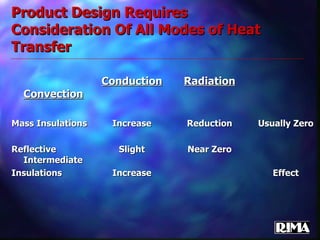

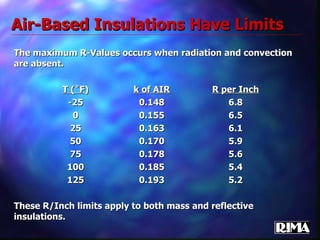

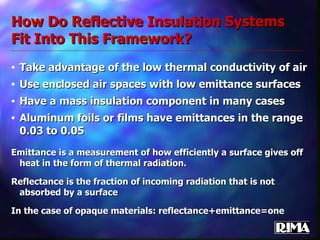

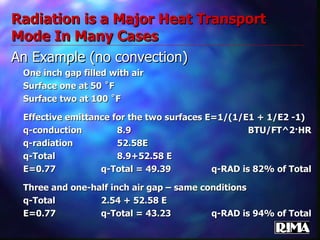

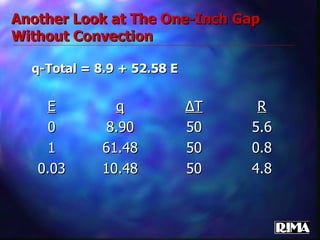

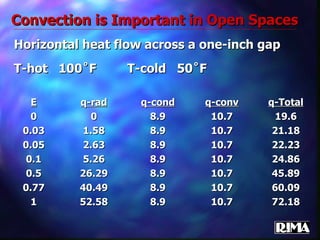

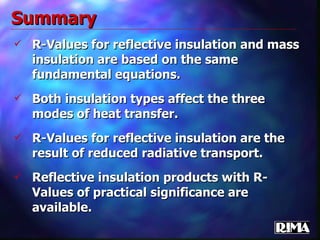

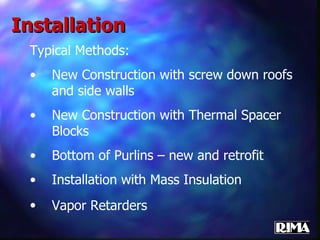

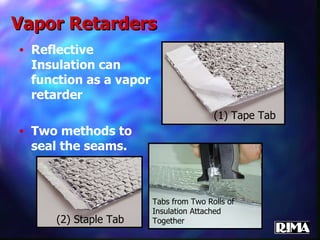

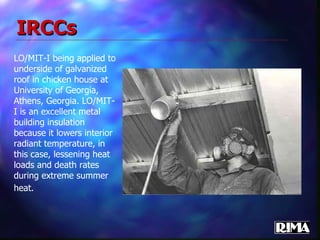

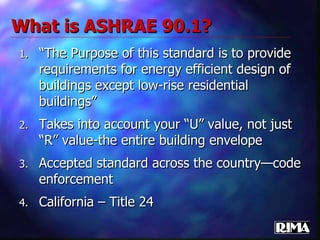

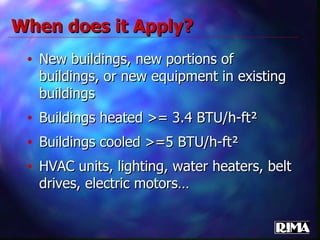

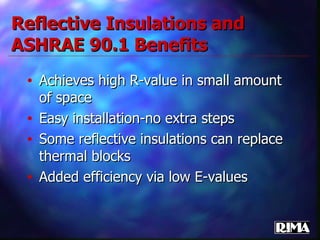

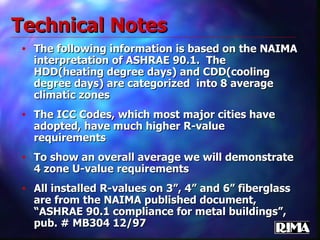

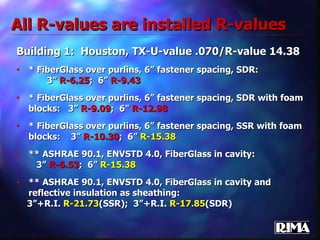

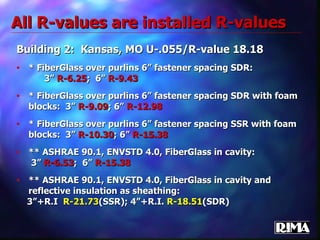

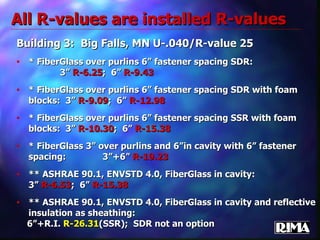

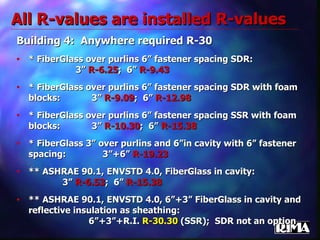

This document discusses R-values and thermal performance of reflective insulation. It provides an overview of how R-values are calculated differently for reflective insulation compared to mass insulation. Reflective insulation takes advantage of the low conductivity of air and uses enclosed low-emittance air spaces to reduce radiative heat transfer. When installed correctly in buildings, reflective insulation can help improve thermal performance and meet requirements of standards like ASHRAE 90.1.