The document provides an overview of a presentation on the Theory of Constraints (TOC). It includes:

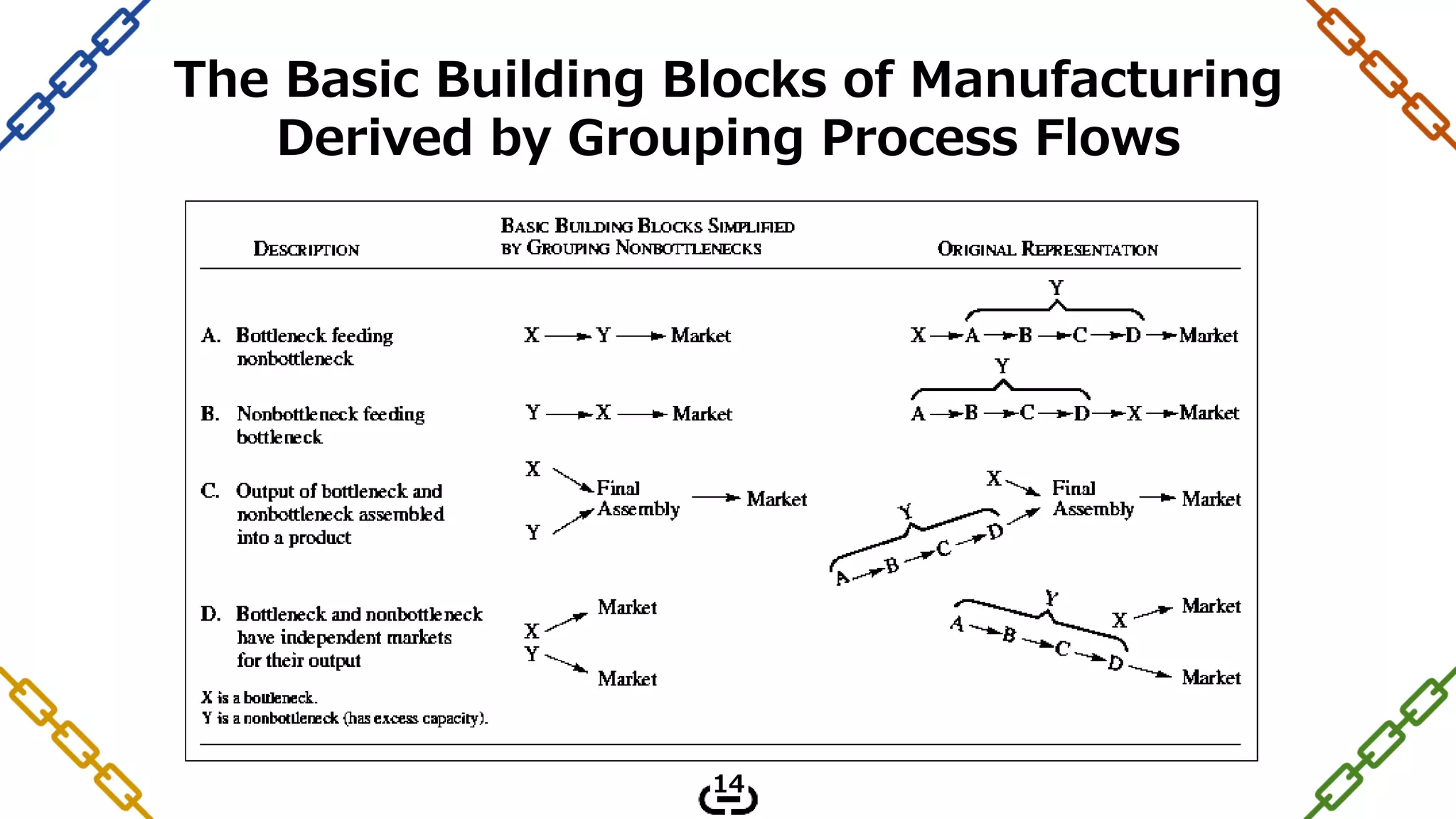

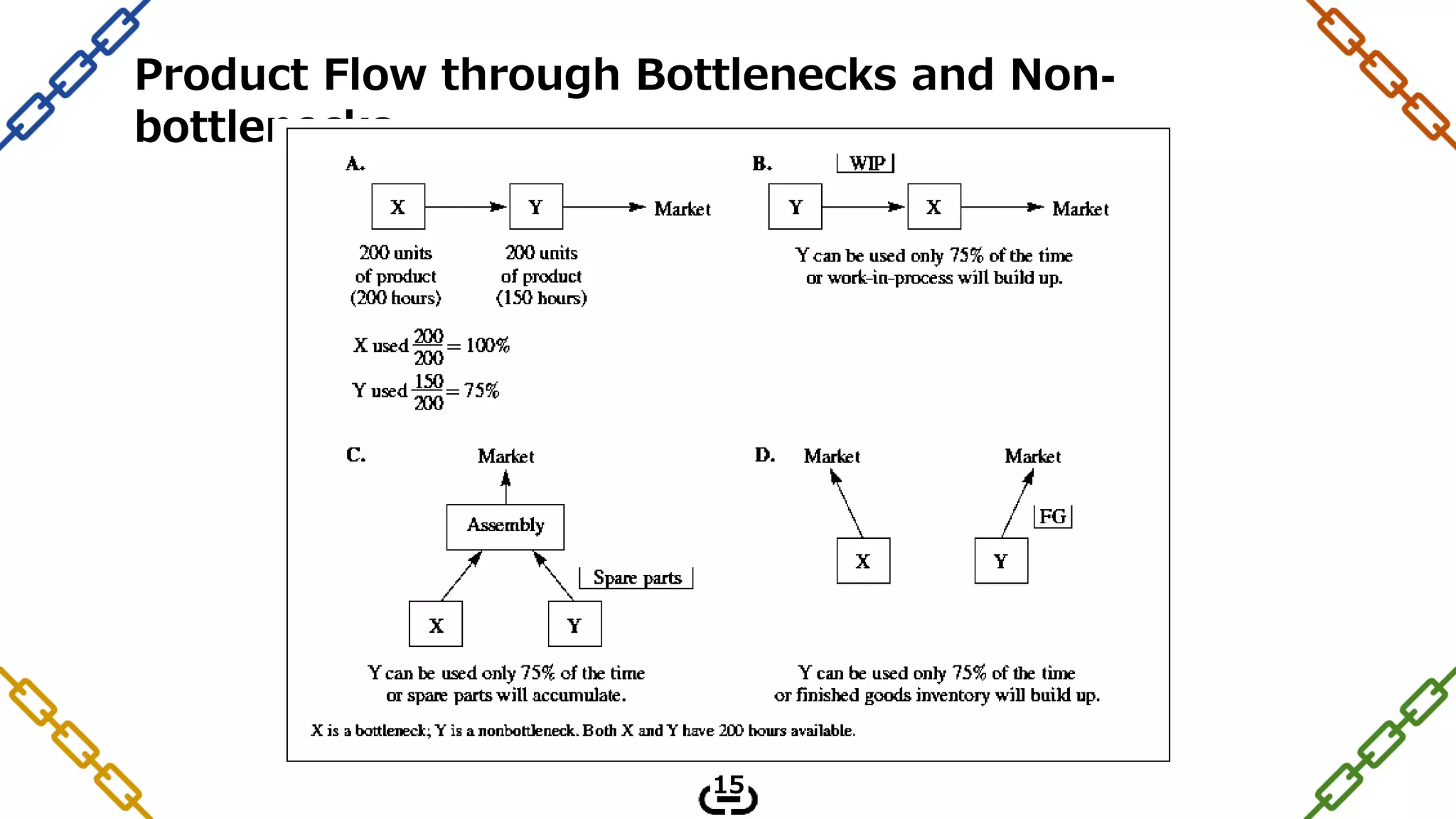

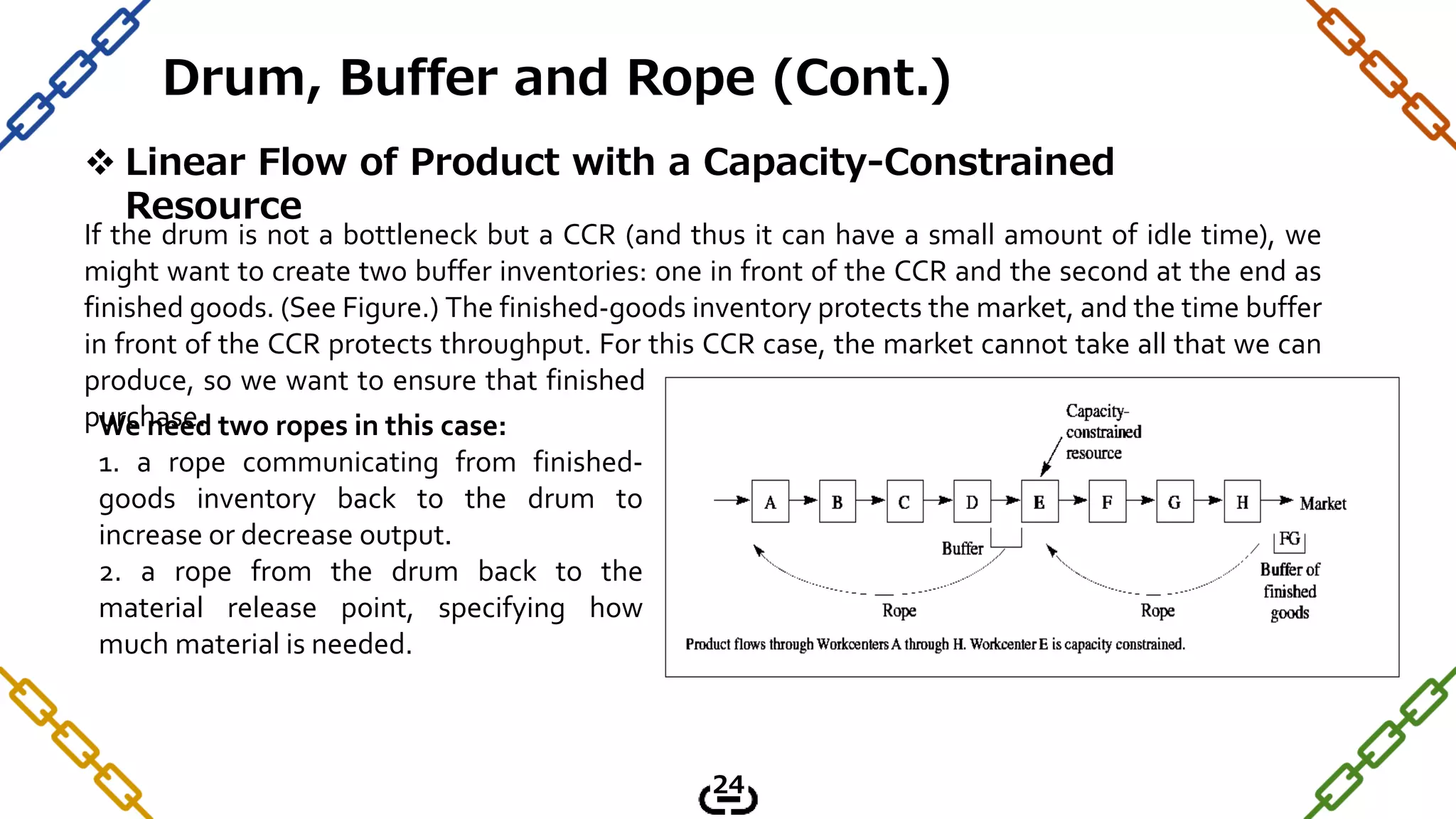

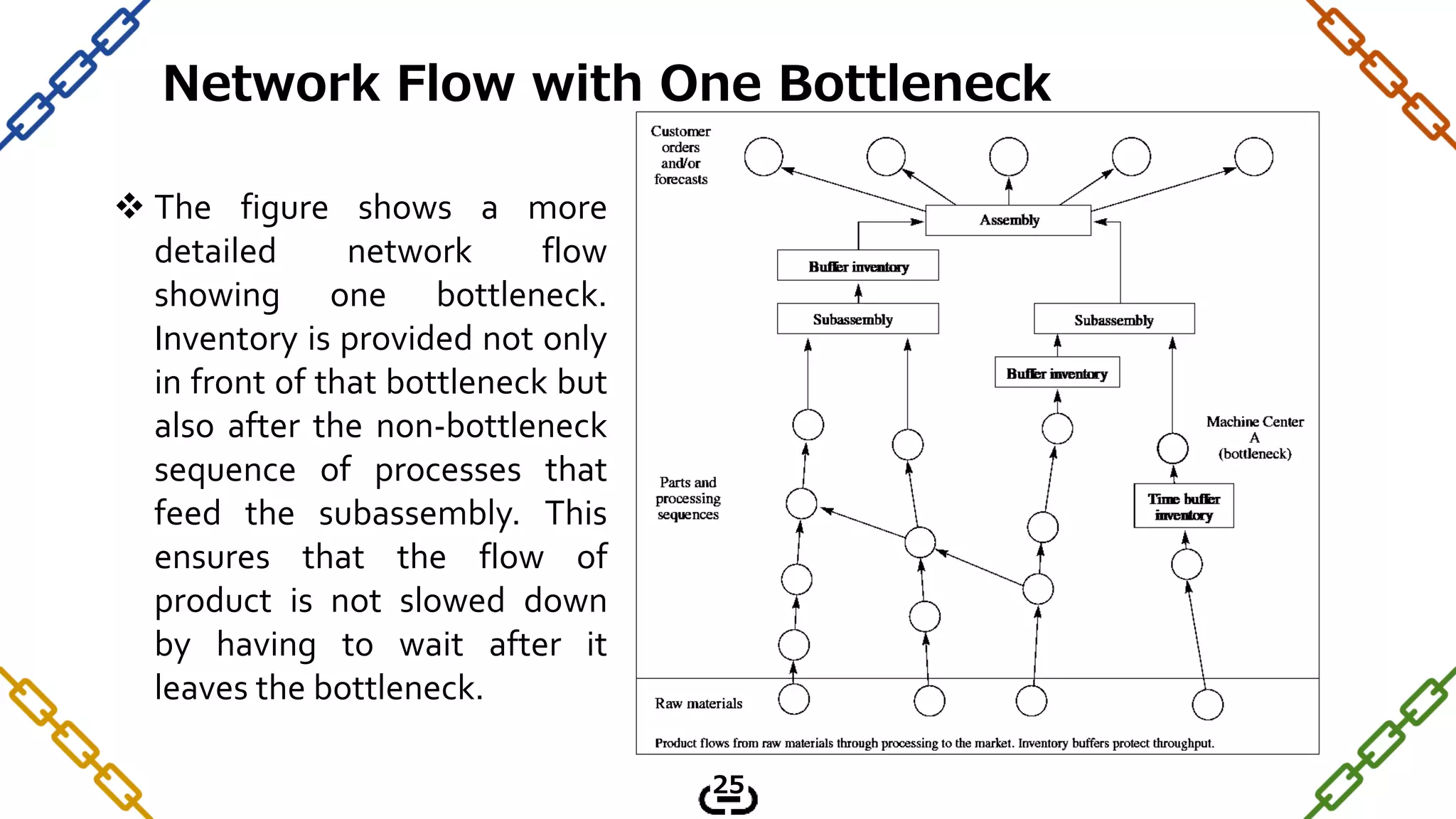

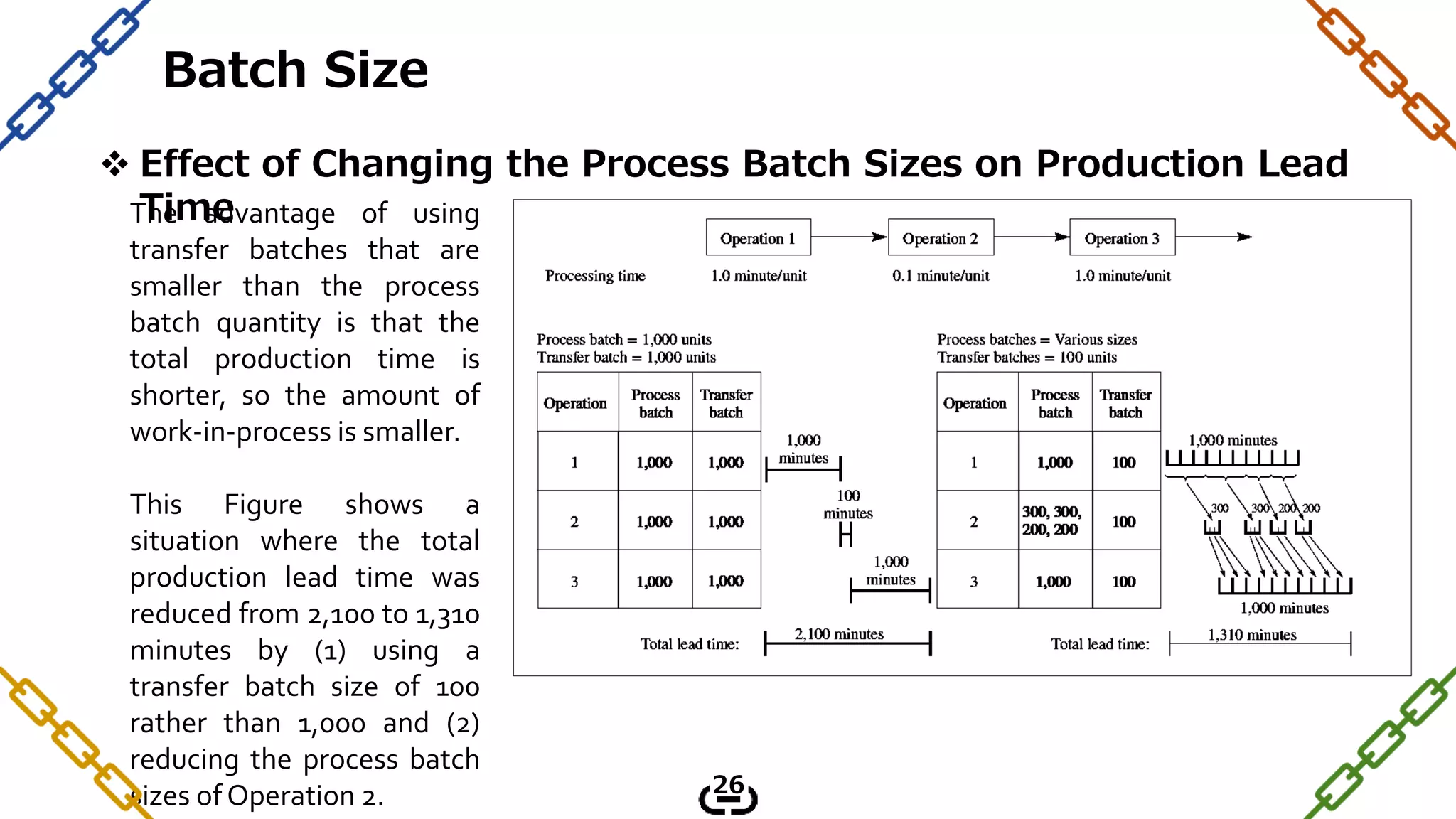

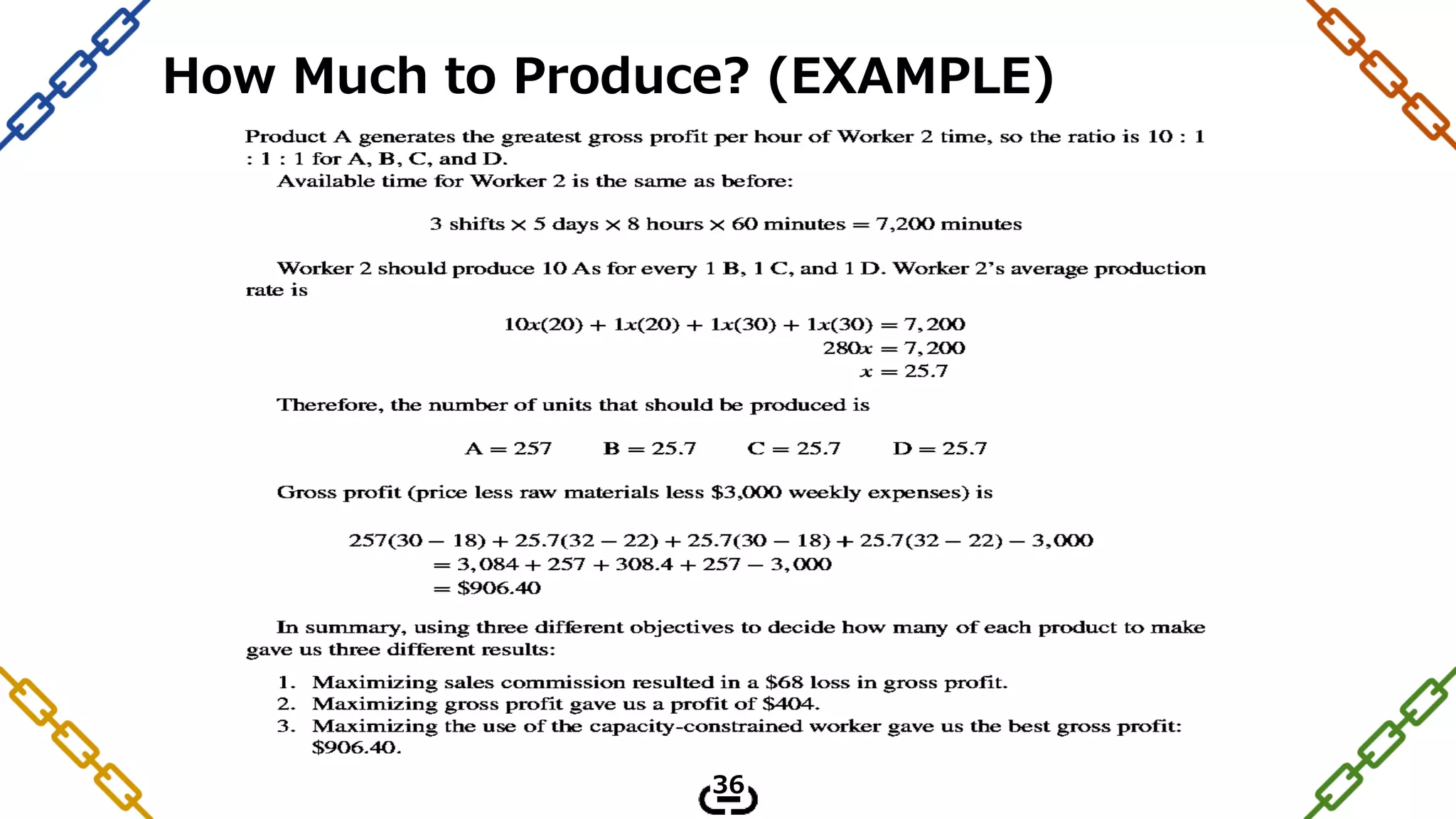

1. An outline of the presentation contents which discusses key TOC concepts like bottlenecks, non-bottlenecks, drum-buffer-rope, and how to determine batch sizes.

2. A story example that demonstrates how changing the constraints of the slowest person in a hiking line (the bottleneck) allows the whole group to move faster.

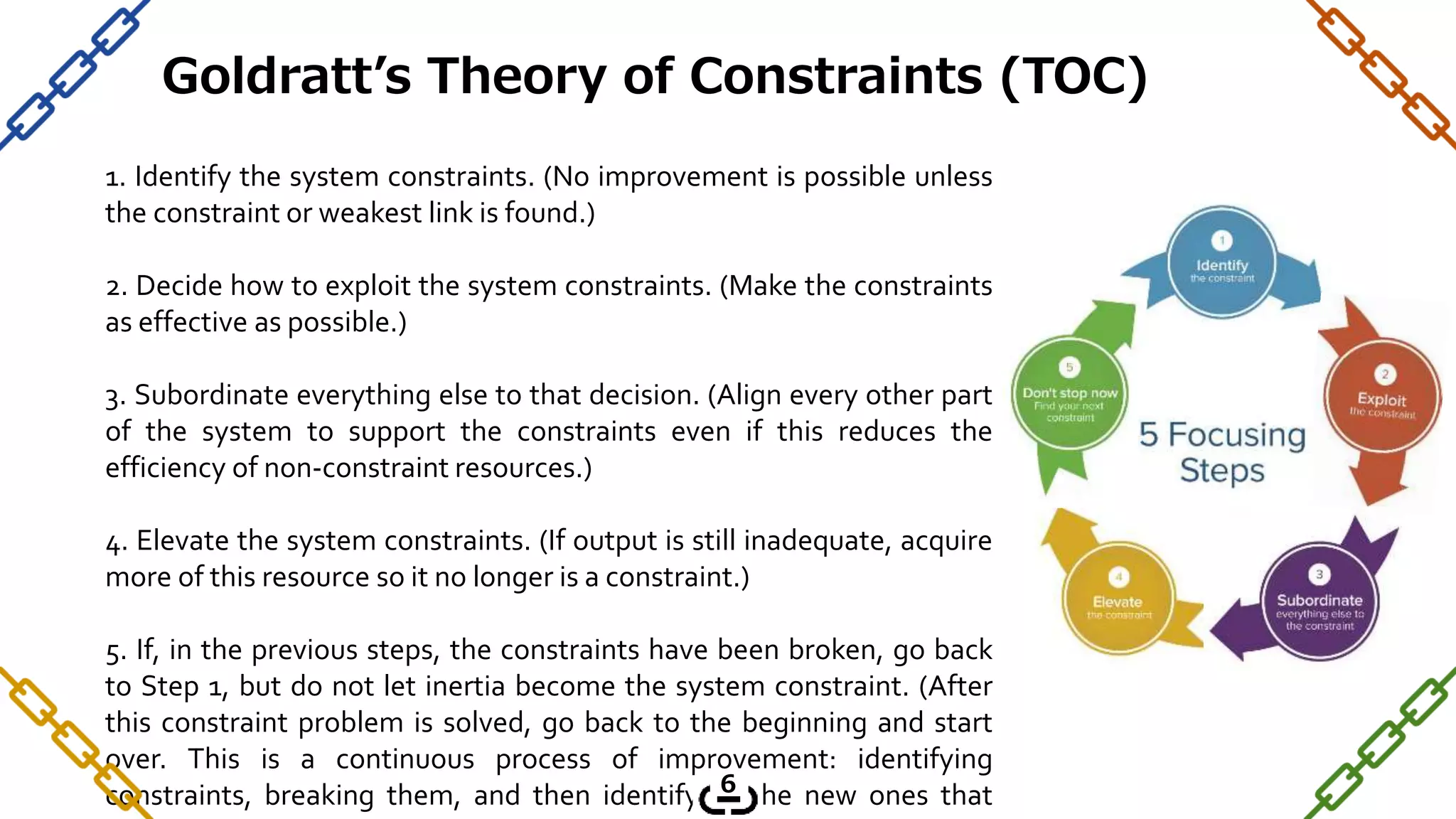

3. Goldratt's rules of production scheduling and the five focusing steps of TOC for improving throughput in a constrained system.