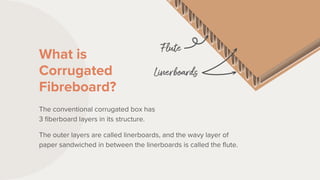

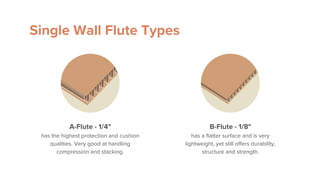

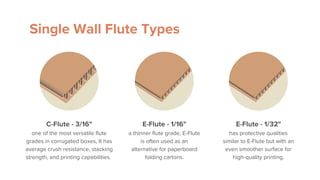

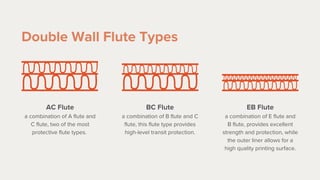

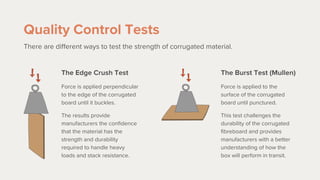

The document provides a comprehensive overview of corrugated packaging, emphasizing its structure, benefits, and types, distinguishing it from cardboard. It highlights the growing demand for corrugated boxes driven by the e-commerce industry and discusses various paper grades used in their production. Additionally, it covers quality control tests for assessing the strength and durability of corrugated materials.