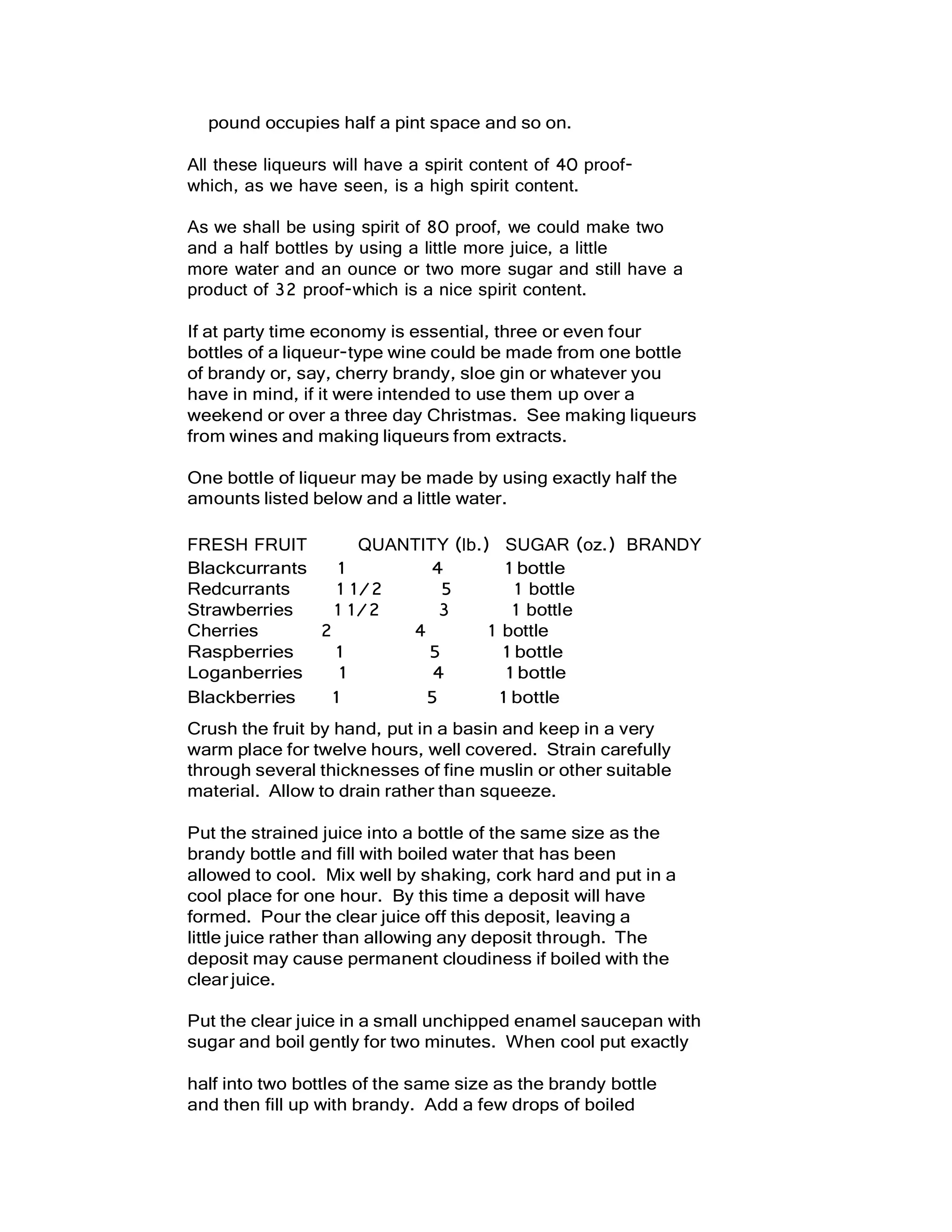

This document provides instructions for making wine at home. It discusses the necessary supplies and utensils, which are minimal and include a glass bottle, enamel saucepan, and plastic pail. The key steps are preparing the fruit or plant ingredients, adding yeast to start fermentation, keeping the fermenting wine warm to facilitate the process, and allowing the wine to fully clear before bottling. Proper preparation and sanitization of equipment helps ensure the wine does not spoil from wild yeasts or bacteria during the process.