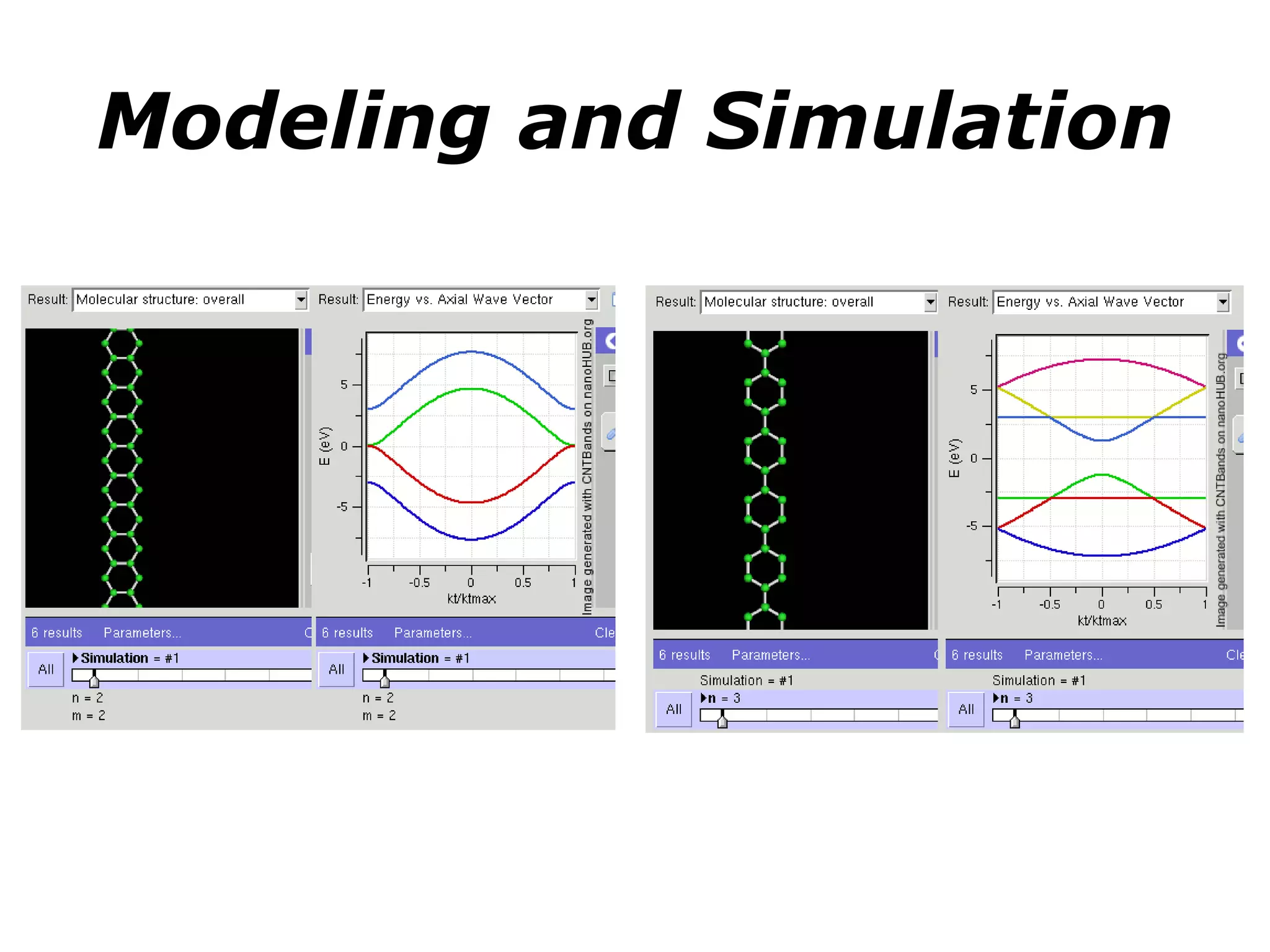

1. The document discusses the importance of materials characterization for understanding nanostructures, quality assurance, and process optimization.

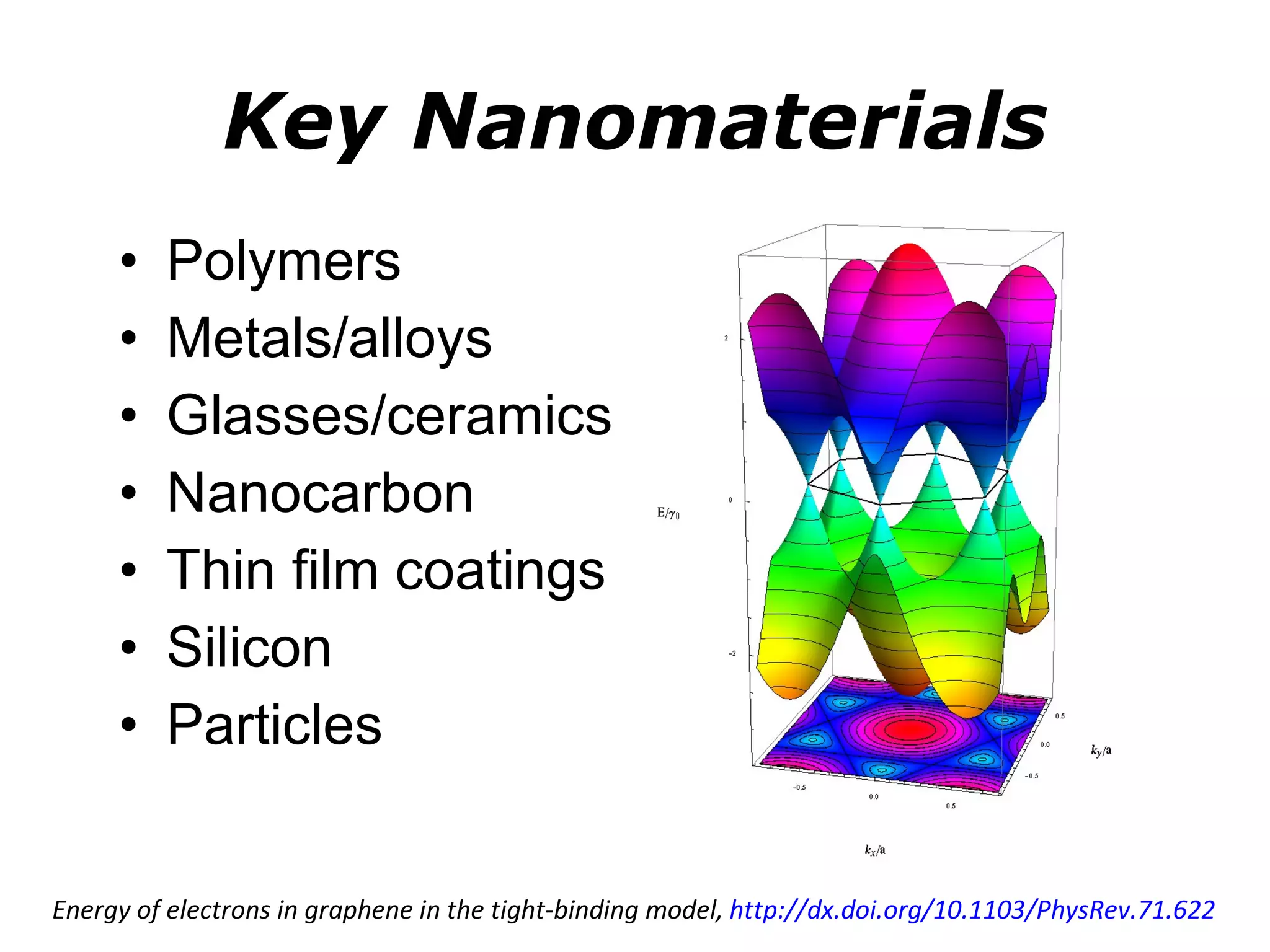

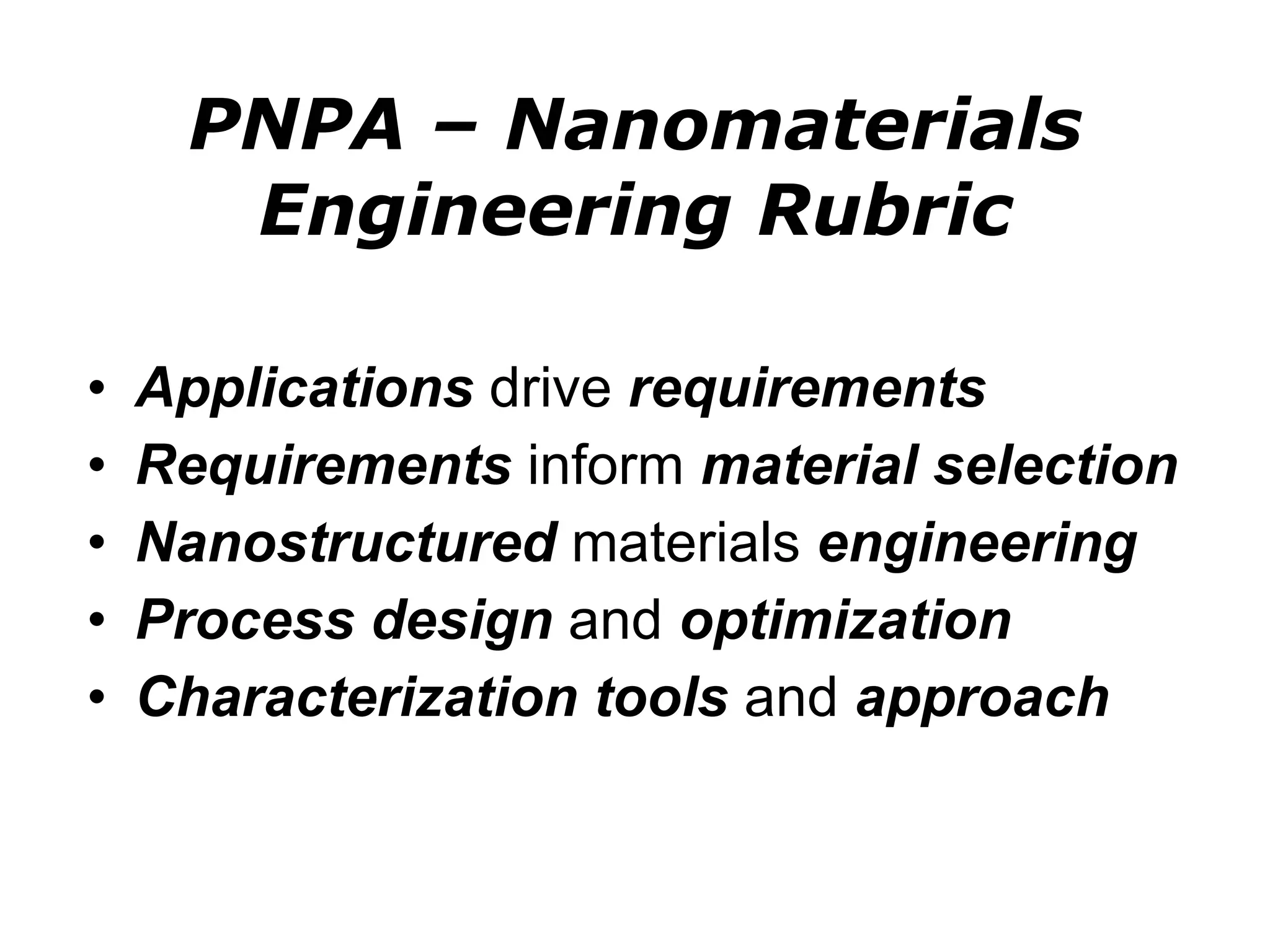

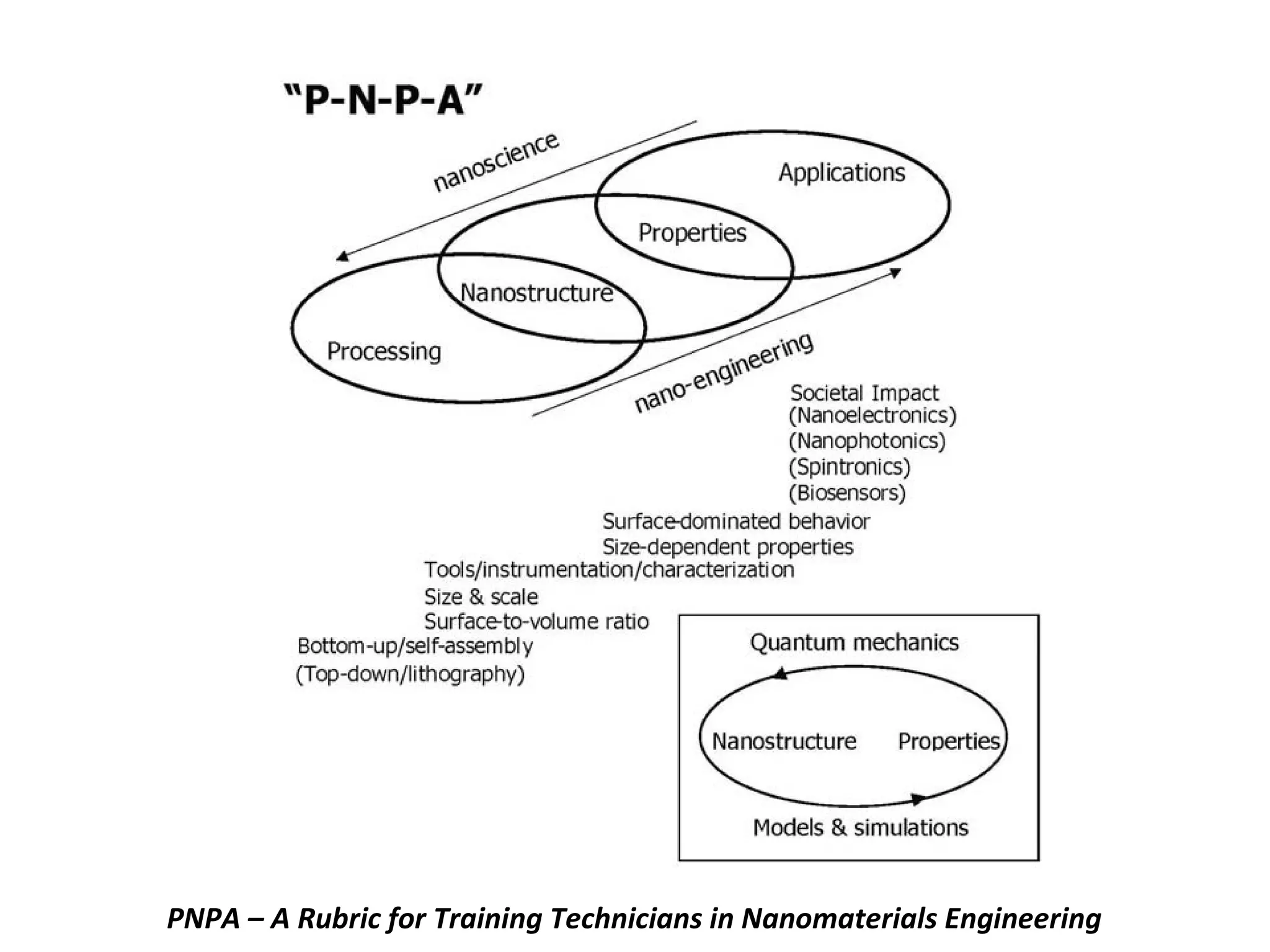

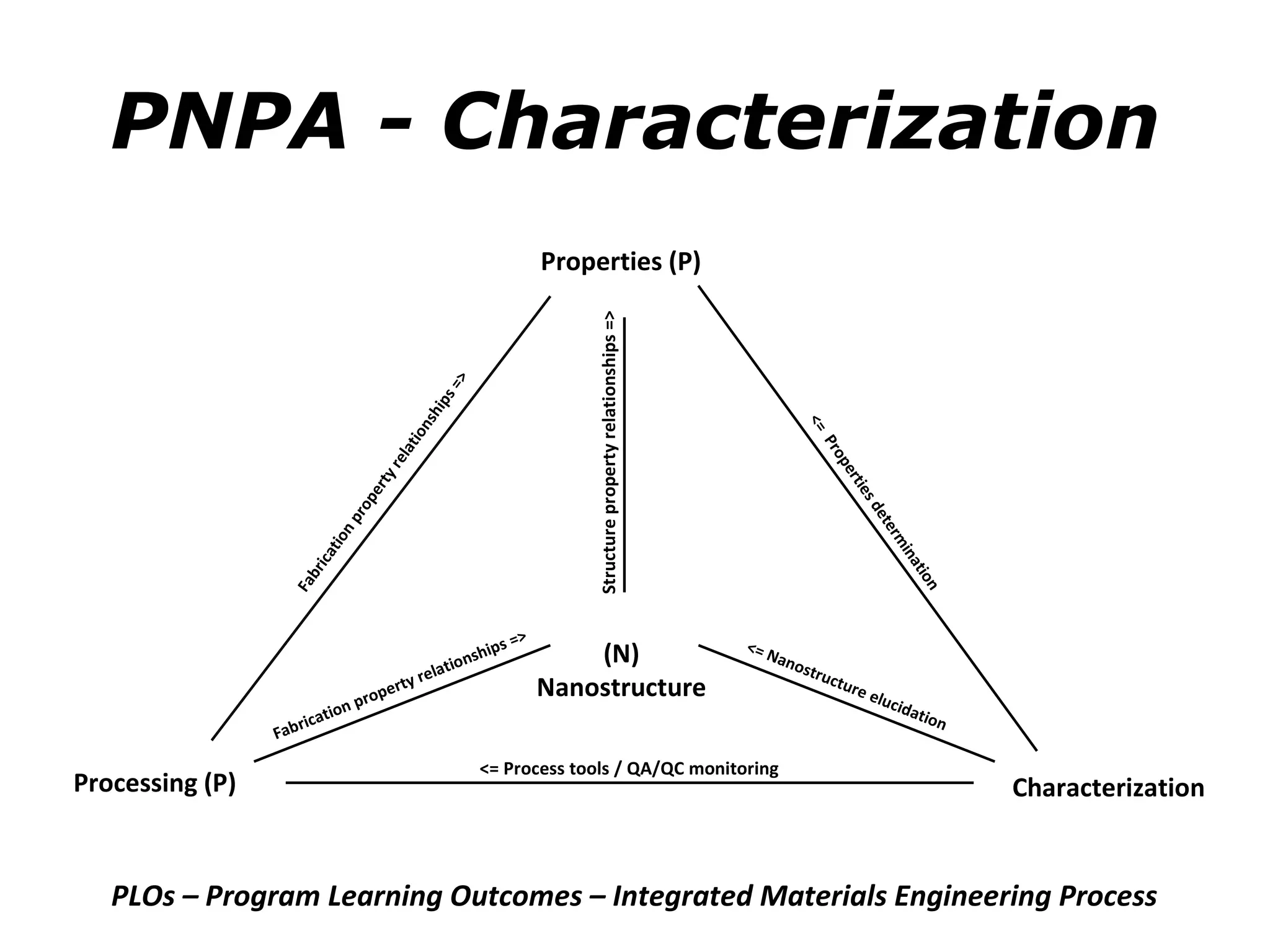

2. It introduces the PNPA model which relates nanostructured materials, processing requirements, and characterization tools and approaches.

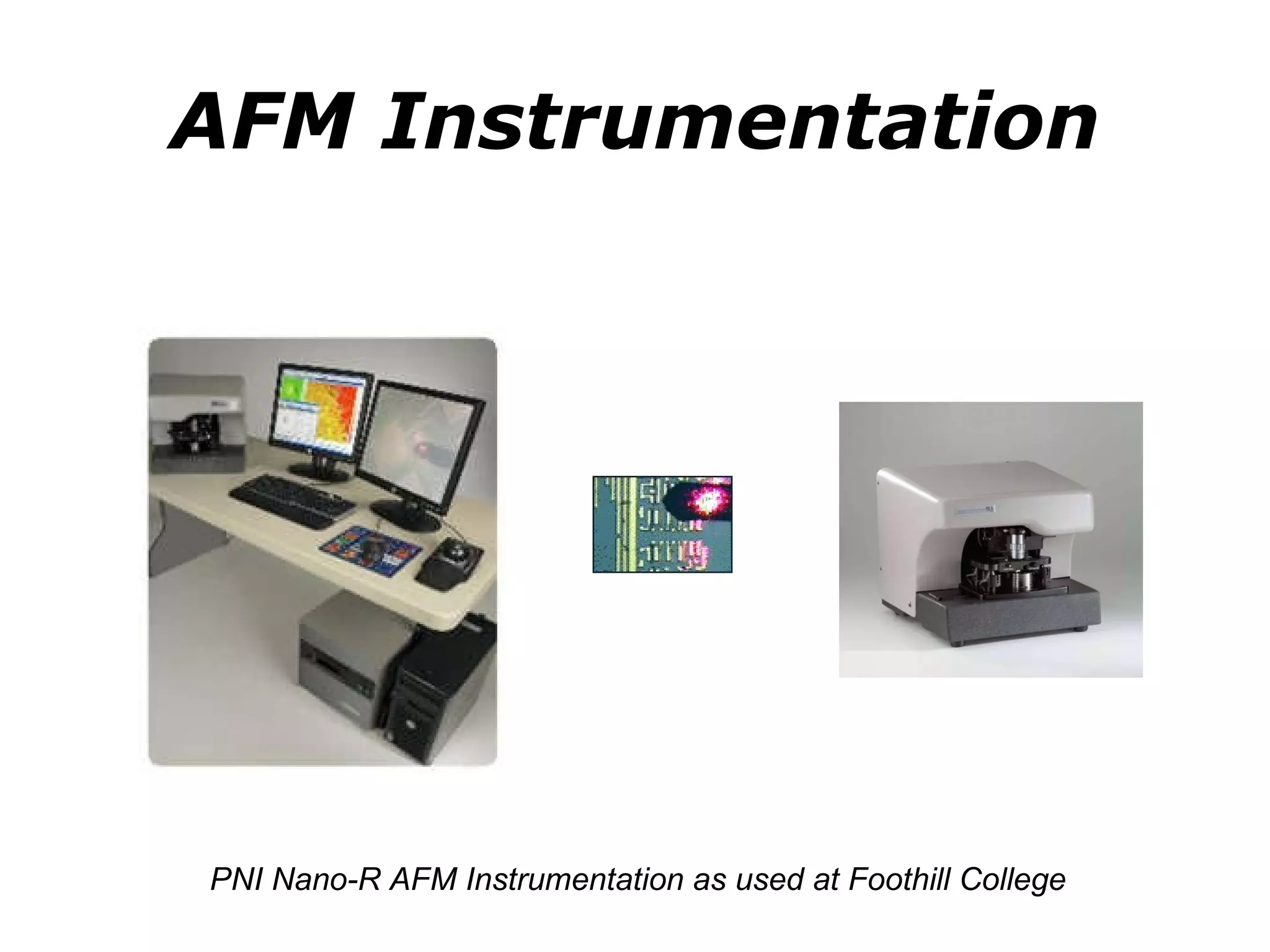

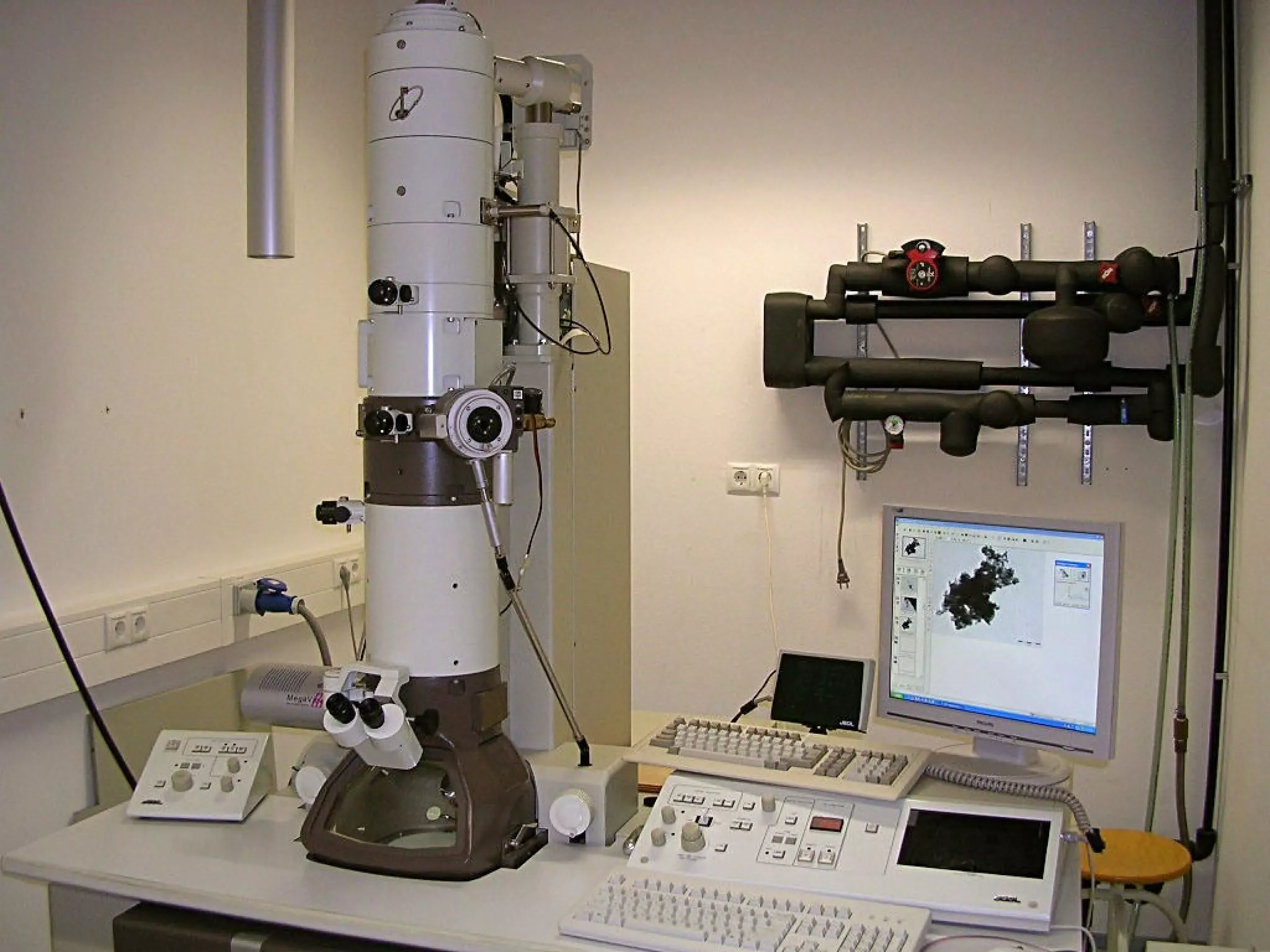

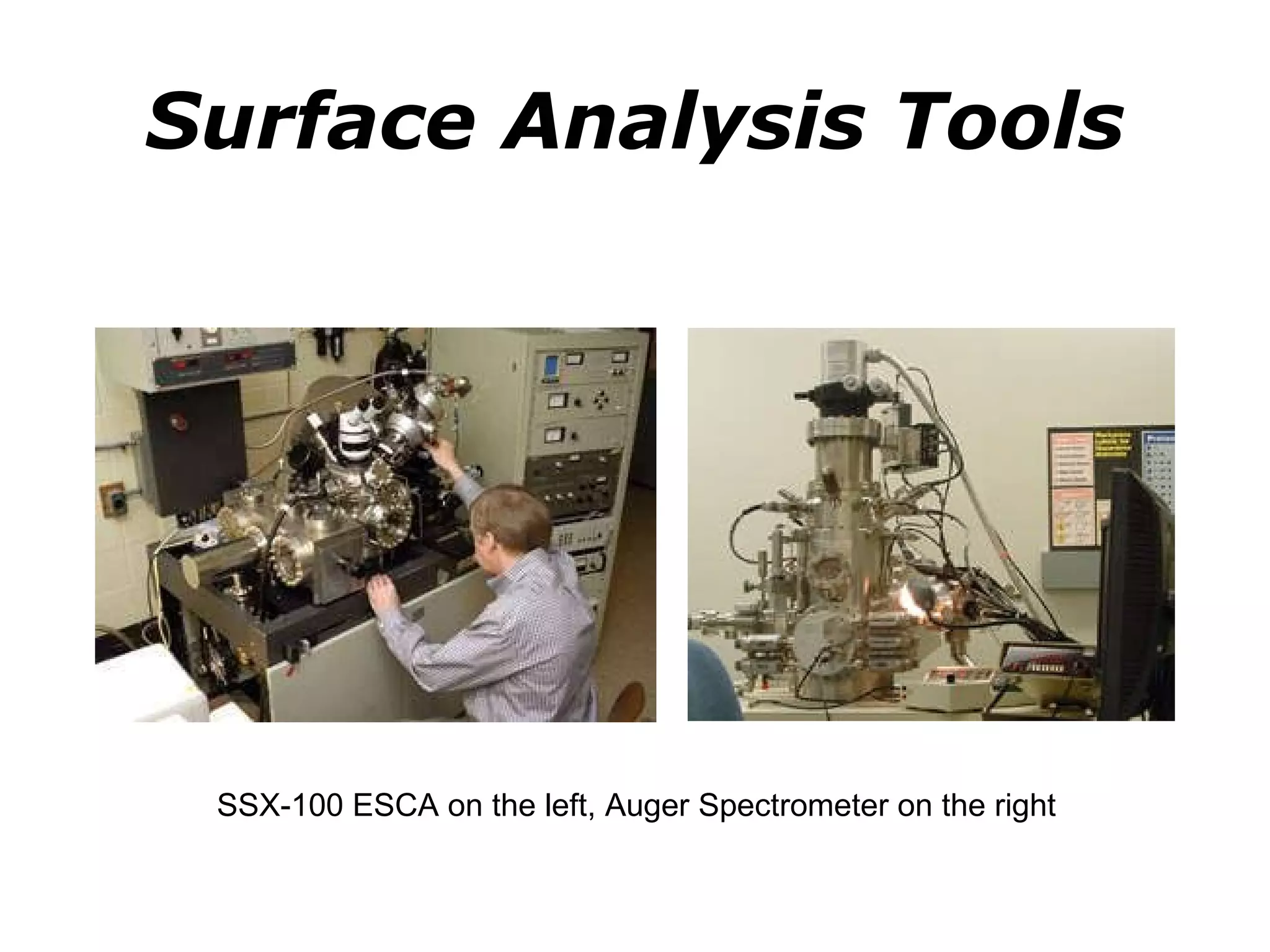

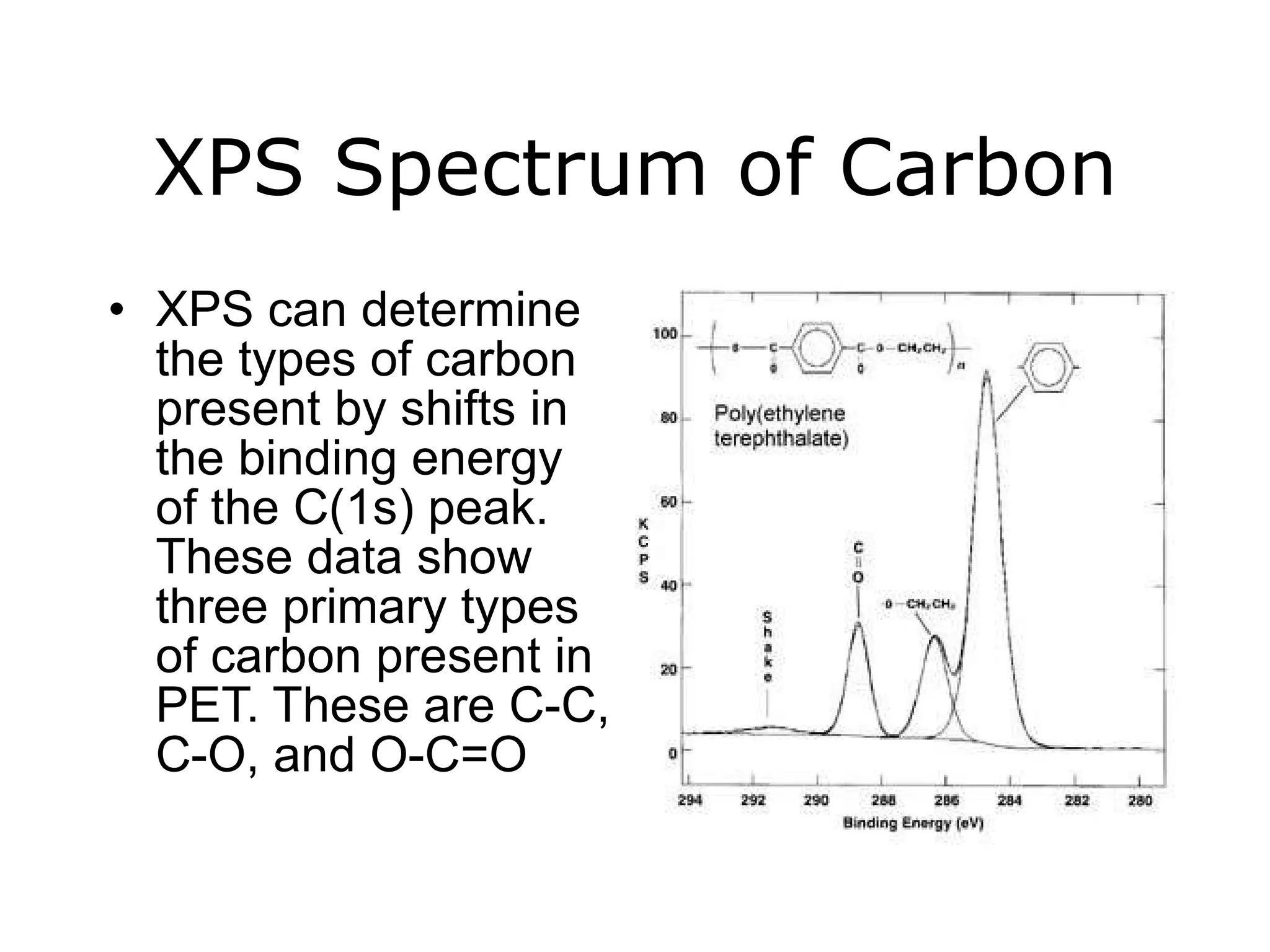

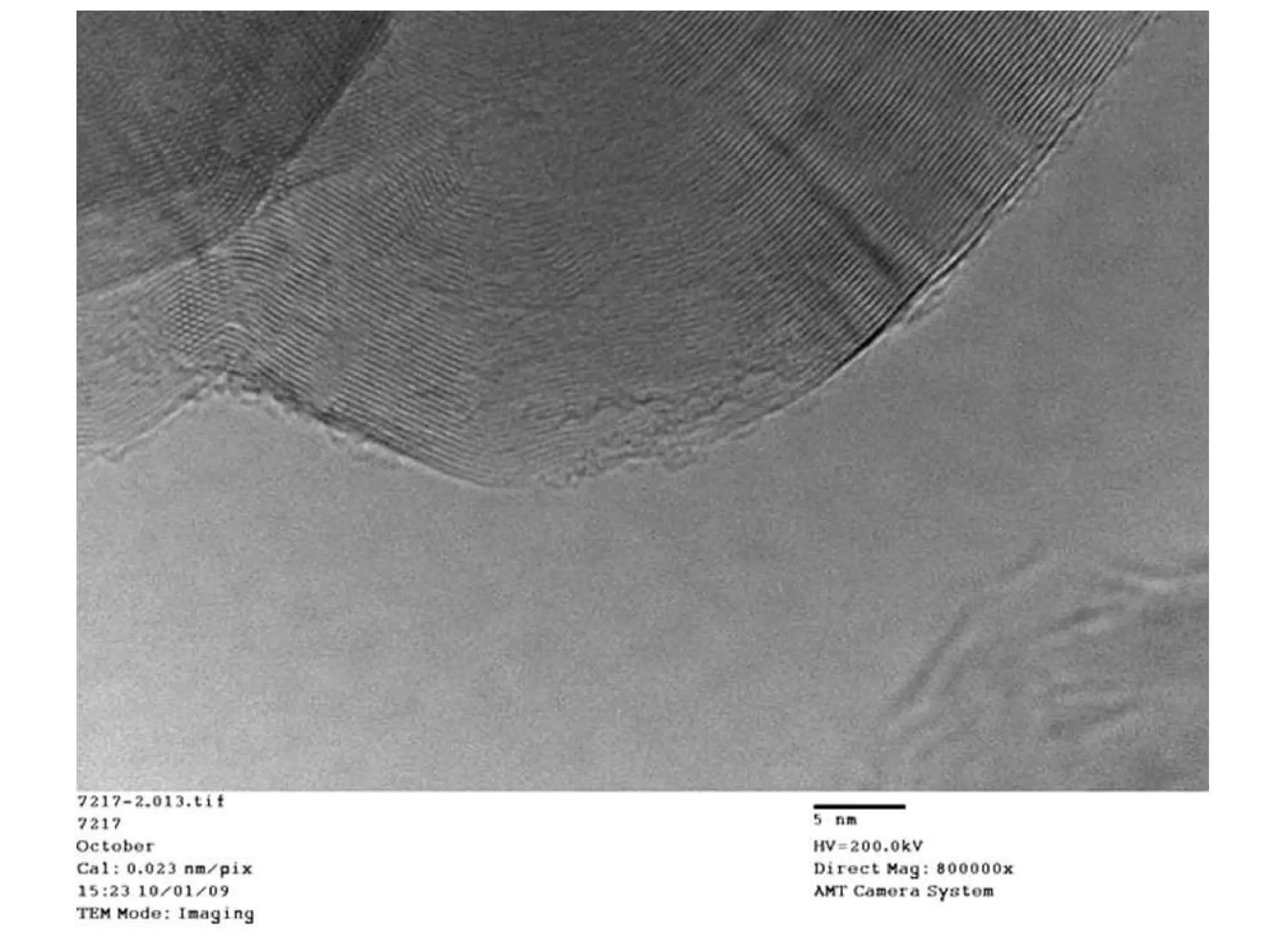

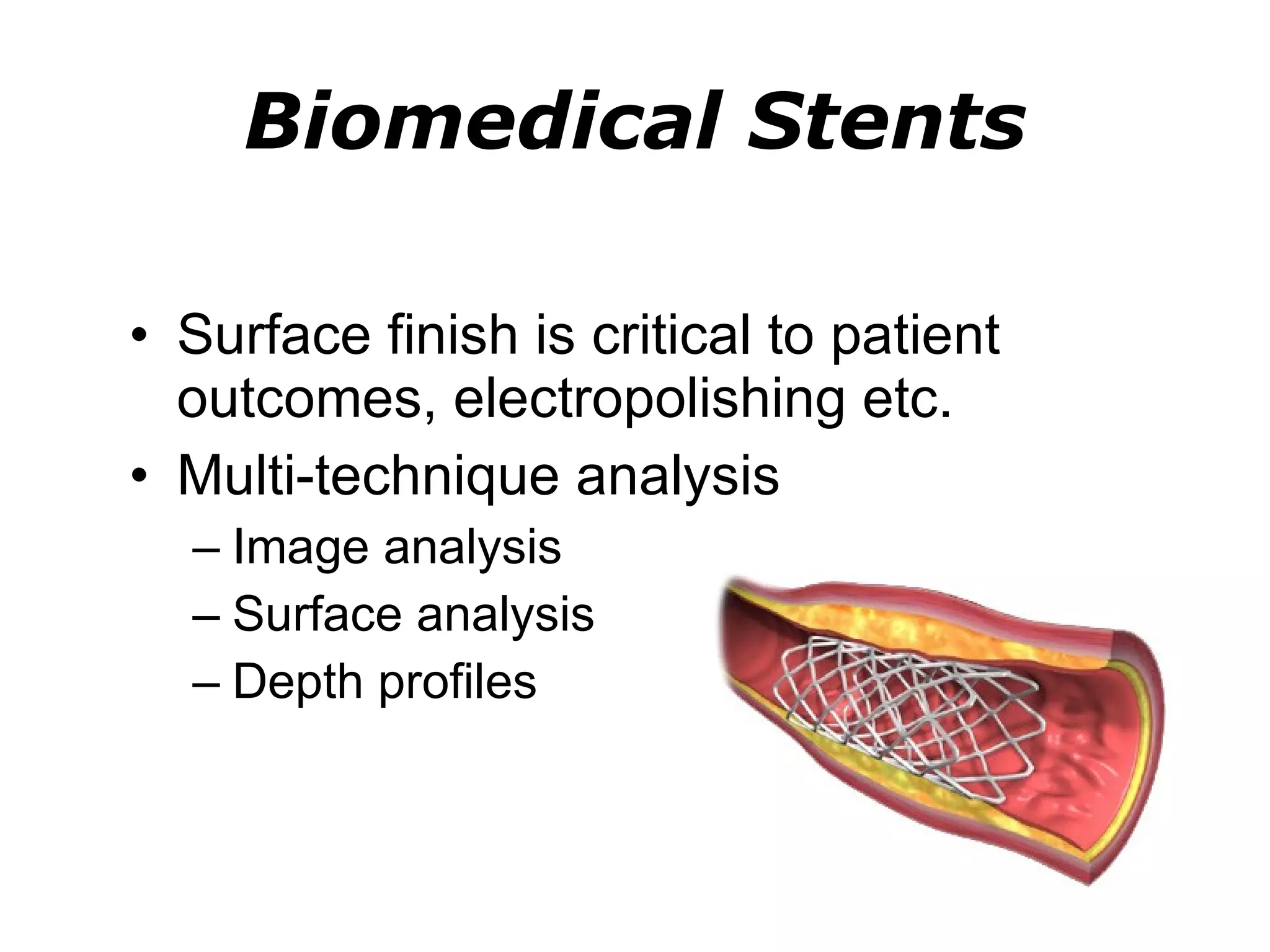

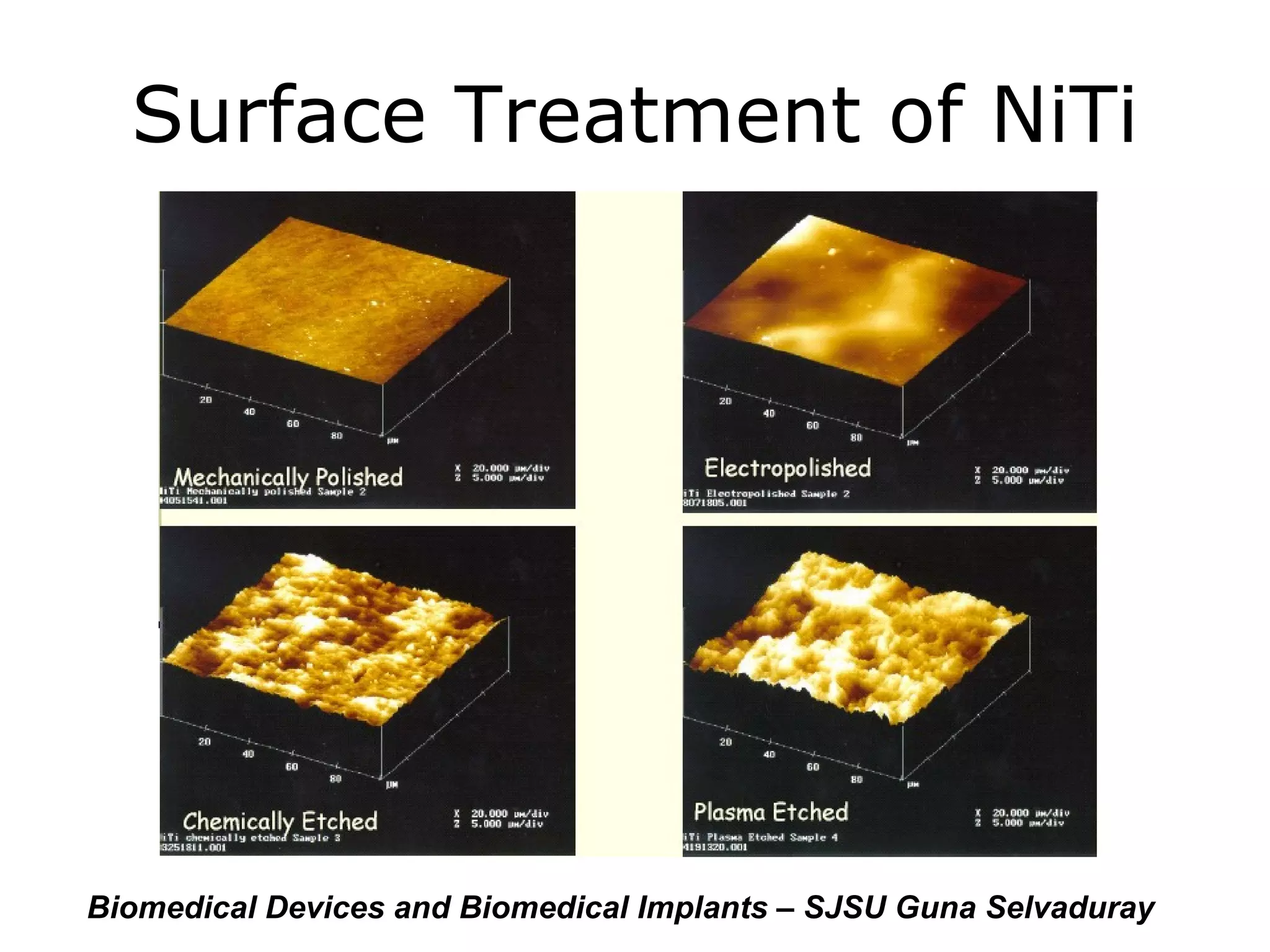

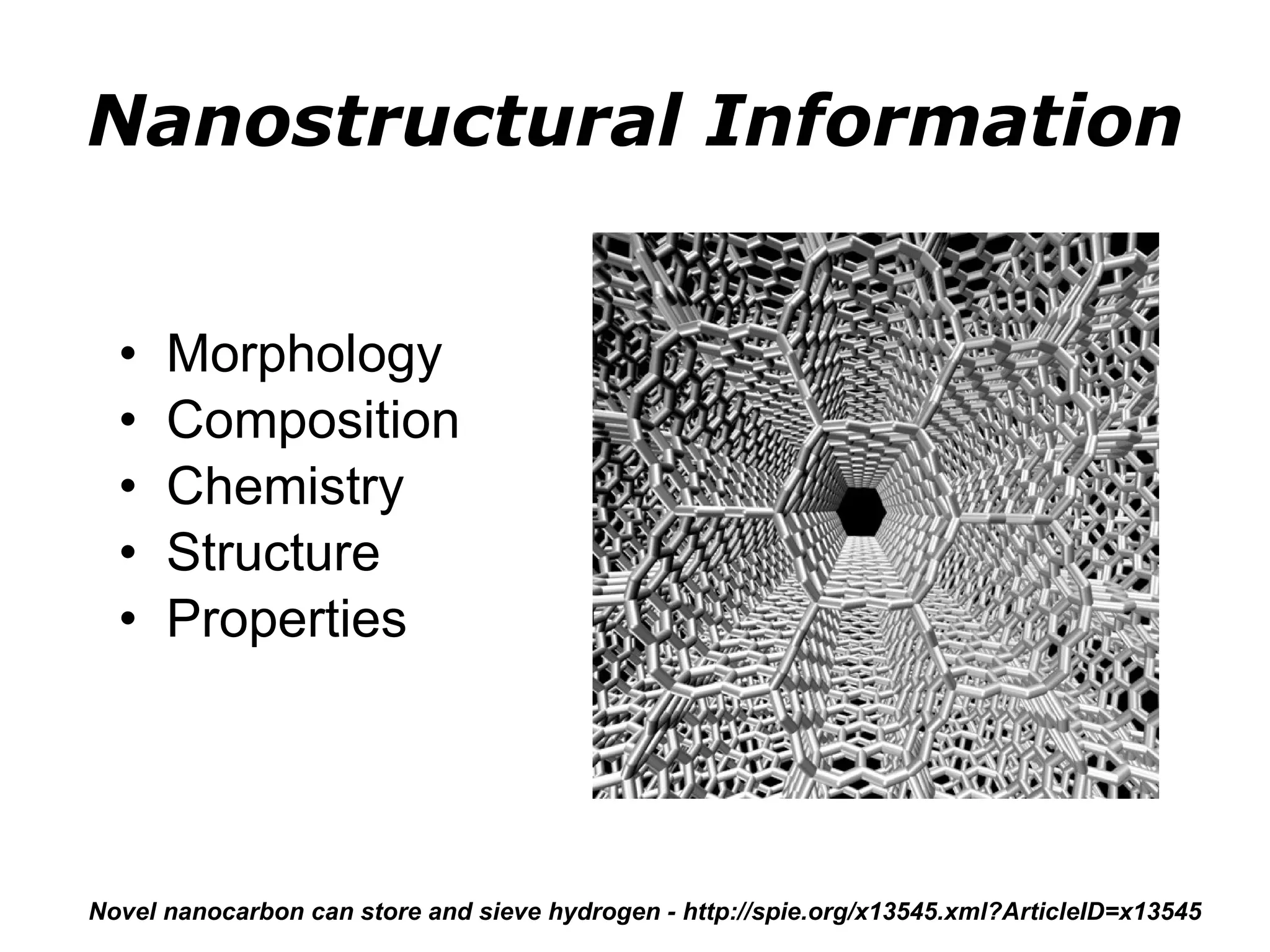

3. Various characterization tools and techniques are described including imaging, surface analysis, organic analysis, and structural and chemical analysis which can provide different types of information about materials.

![Taguchi Methods Taguchi methods are statistical methods developed by Genichi Taguchi to improve the quality of manufactured goods, and more recently also applied to, engineering, biotechnology, marketing and advertising. Professional statisticians have welcomed the goals and improvements brought about by Taguchi methods, particularly by Taguchi's development of designs for studying variation, but have criticized the inefficiency of some of Taguchi's proposals. [5] http://en.wikipedia.org/wiki/Taguchi_methods](https://image.slidesharecdn.com/thecaseformaterialscharacterization-110926161316-phpapp01/75/The-Case-for-Materials-Characterization-9-2048.jpg)