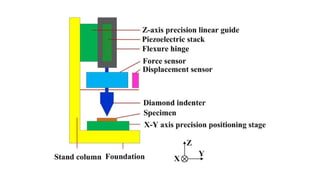

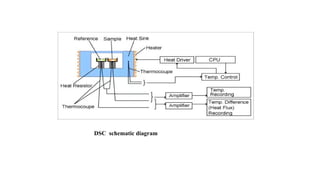

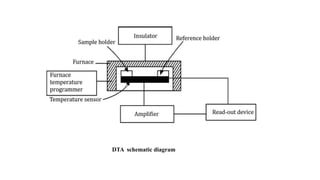

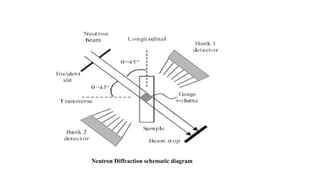

Introduction to Orientation Imaging Microscopy (OIM), 3-Dimensional FIB/EBSD, Insitu testing facilities, Nano indentation, Combined spectroscopy and microscopy techniques, Temperature related measurement (TG+DTA) and DSC, Thermomechanical physical simulator, Gleeble, Neutron diffraction techniques.