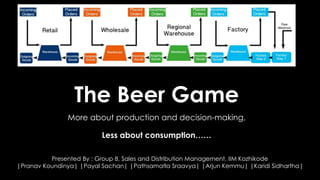

The Beer Game is a simulation that models the bullwhip effect in supply chains. It involves four stages - retailer, wholesaler, distributor, and factory. The simulation showed increasing swings in orders as information moved up the supply chain, with the factory receiving the most volatile orders despite stable consumer demand. This caused high and fluctuating inventory levels. Stockouts also occurred, especially at the retailer level, further increasing costs. Overall, the simulation demonstrated how lack of coordination between supply chain stages can damage costs and service quality.