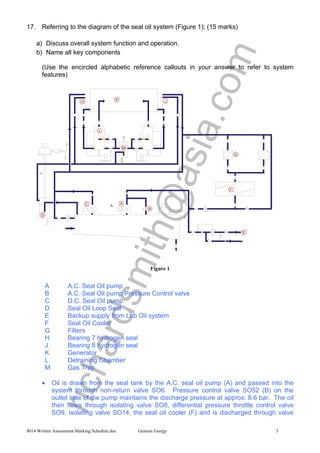

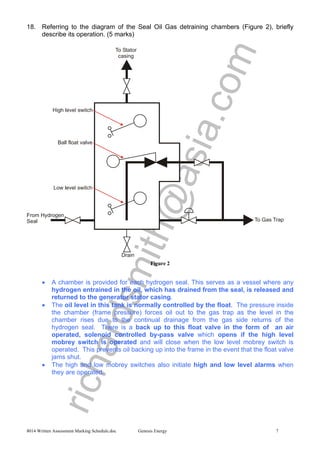

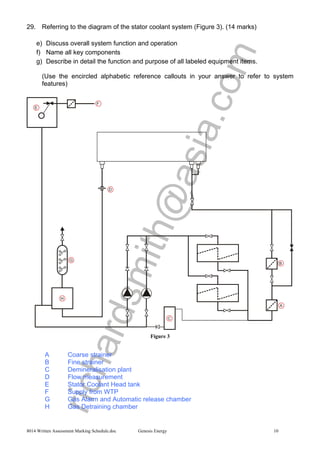

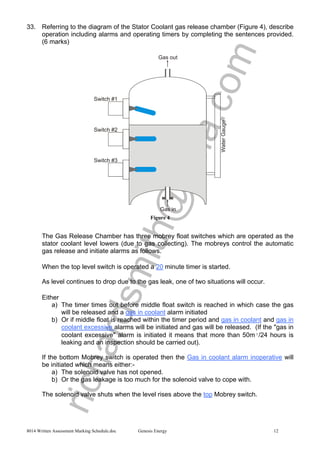

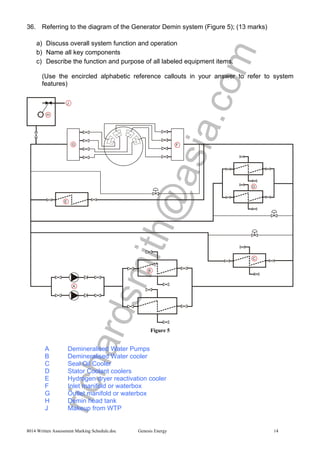

The document provides an assessment marking schedule for a power station operations training course. It includes 29 multiple choice and short answer questions about various systems in a power station including the generator, seal oil system, stator coolant system, and hydrogen system. Key topics covered include causes of heat generation in the generator, operating pressures and temperatures of hydrogen and seal oil, advantages and disadvantages of using hydrogen as a coolant, and functions of components in the seal oil and stator coolant systems. Diagrams of the seal oil and stator coolant systems are included and referred to in some questions.