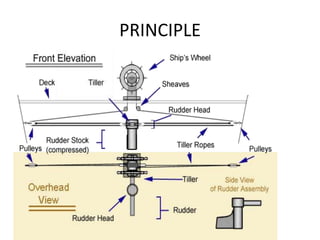

The document outlines the components and operation of a telemotor steering gear system, including types such as fully hydraulic, electro-hydraulic, and fully electric. It explains the functioning of the telemotor control, the power unit, and the transmission system which enables the rudder movement based on signals from the bridge. Regular maintenance, emergency protocols, and control testing procedures are also addressed to ensure operational reliability and responsiveness of the steering system.