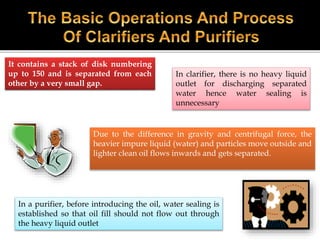

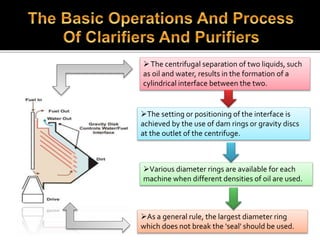

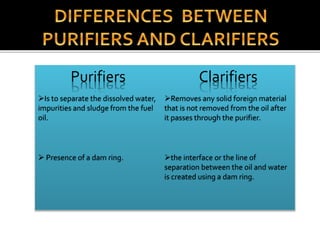

The document discusses methods for purifying fuel oil and lubricating oil through gravity separation and centrifuging techniques. It explains how purifiers and clarifiers work, highlighting their roles in removing impurities, solids, and water from liquids, and the importance of proper maintenance and operation. The document also details the components and functionality of filters used in marine systems to prevent contamination.