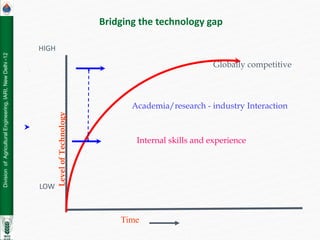

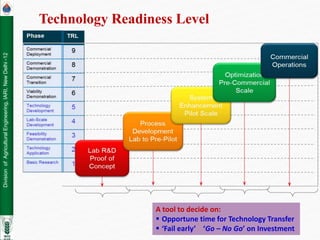

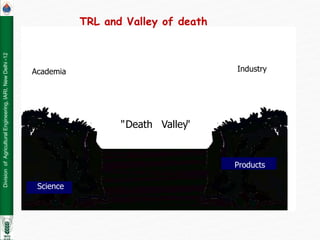

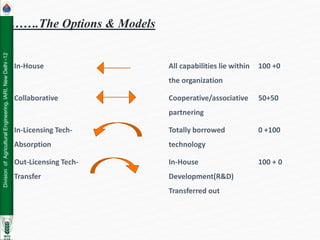

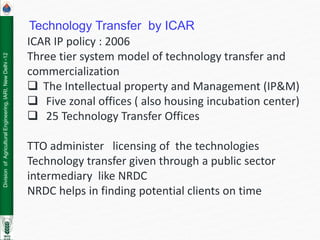

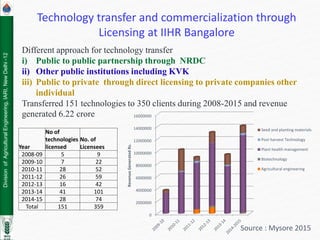

This document discusses technology transfer from research institutions to commercial organizations. It begins by defining technology transfer and the technology readiness level (TRL) scale. It then discusses bridging the "valley of death" between low TRL in research and high TRL practical applications. Various models for technology transfer are presented, including in-house development, licensing, collaborations, and outsourcing. Case studies of technology transfer from the Indian Agricultural Research Institute and the Indian Institute of Horticultural Research are provided. The document concludes that greater industry involvement during research and more training programs could help facilitate technology transfer.