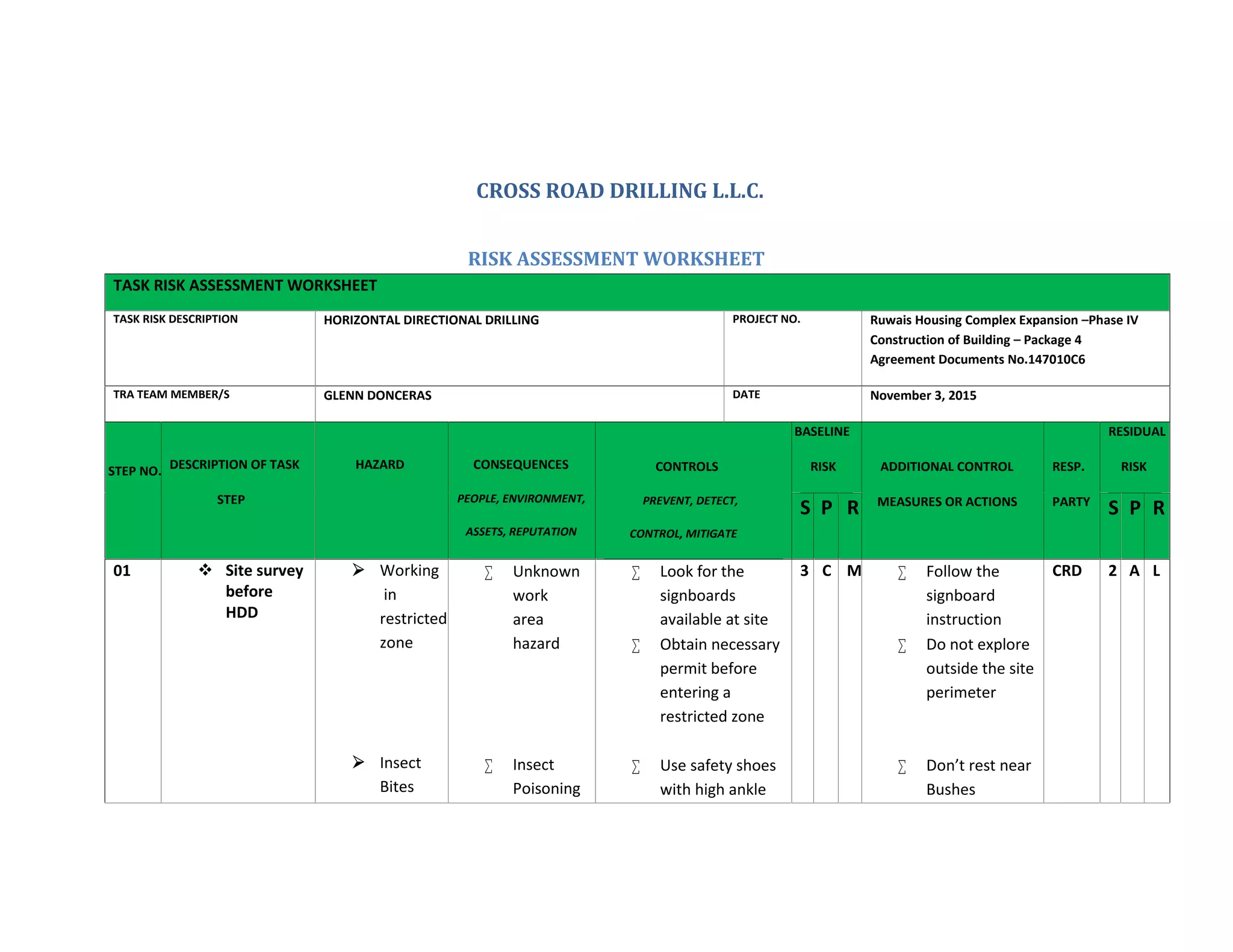

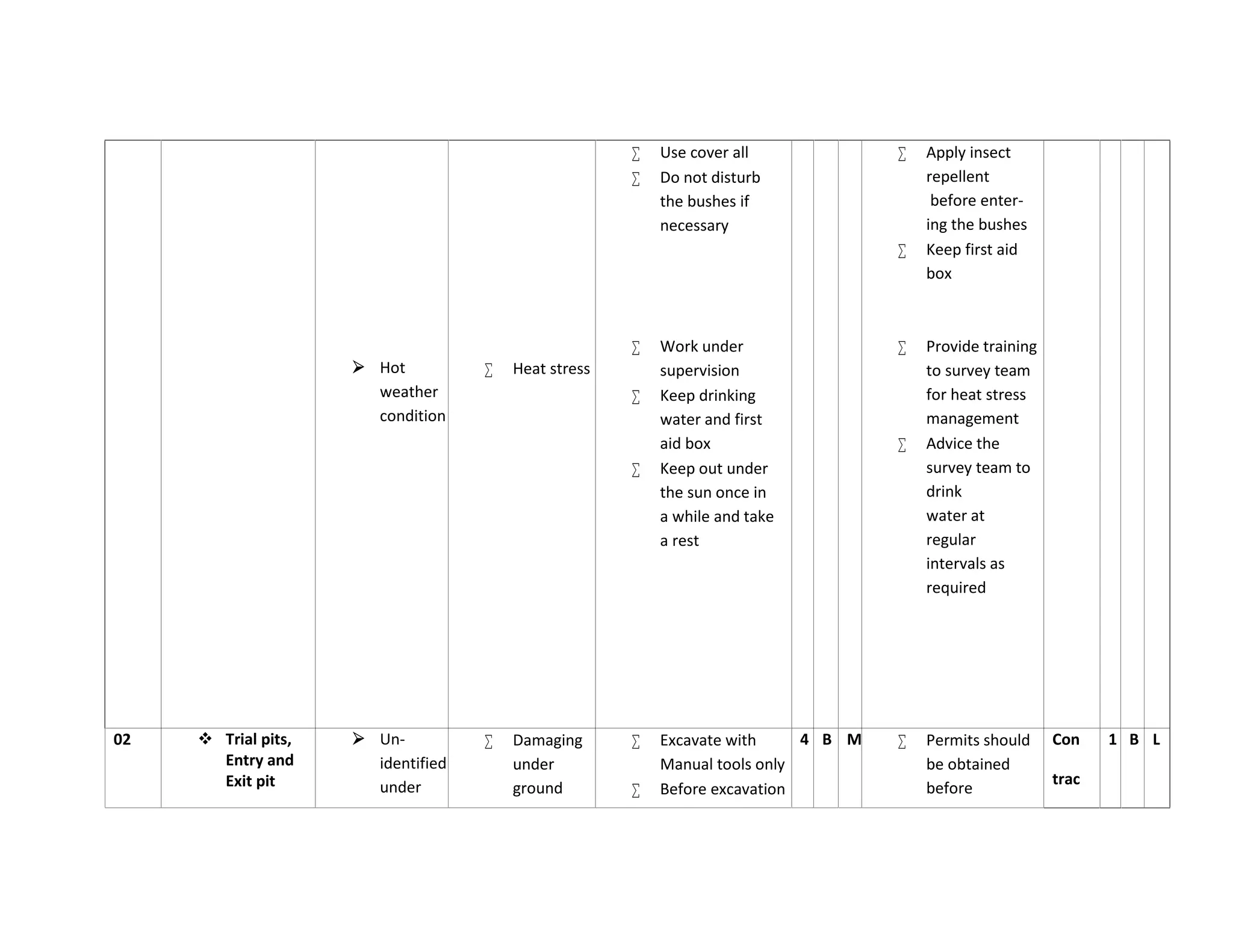

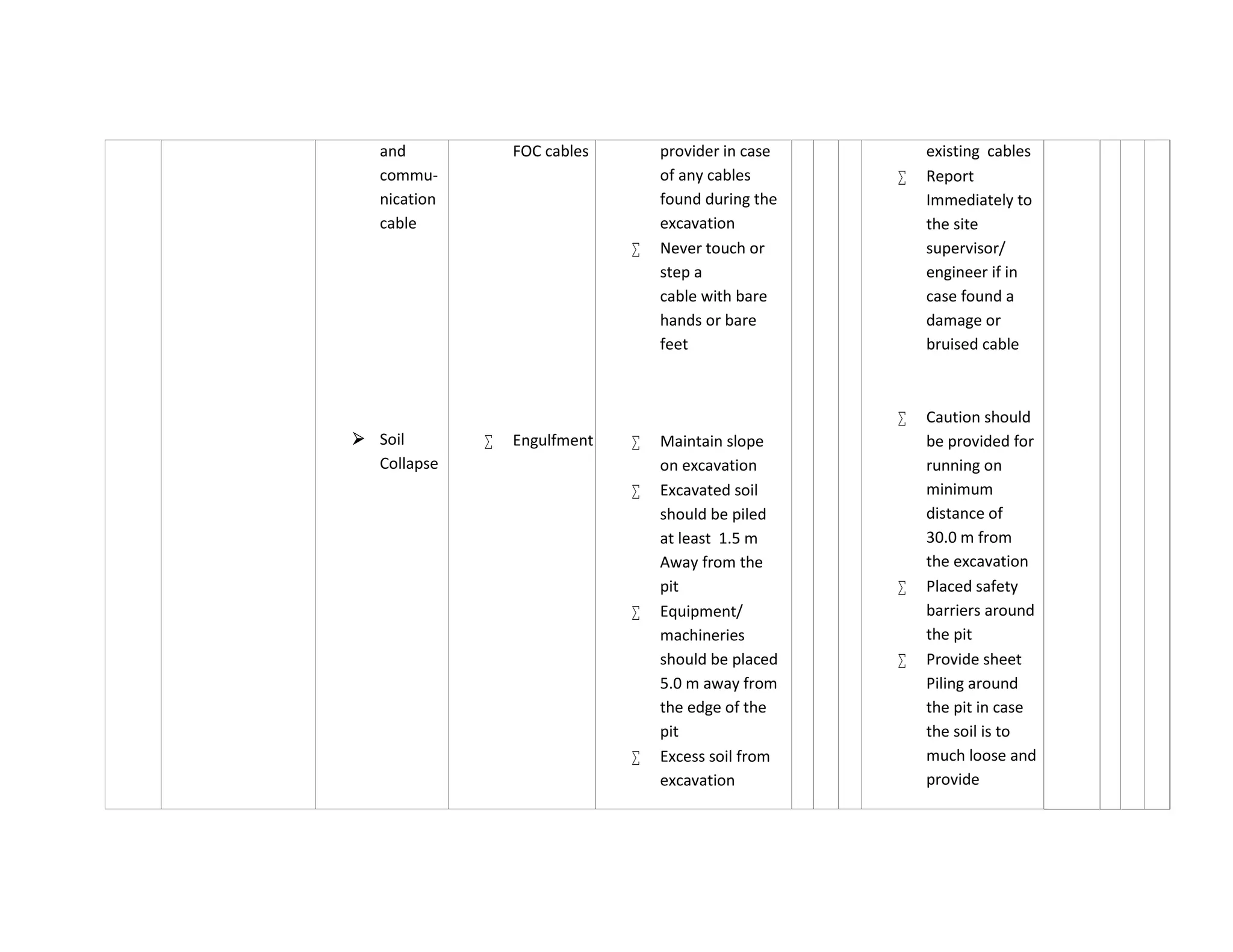

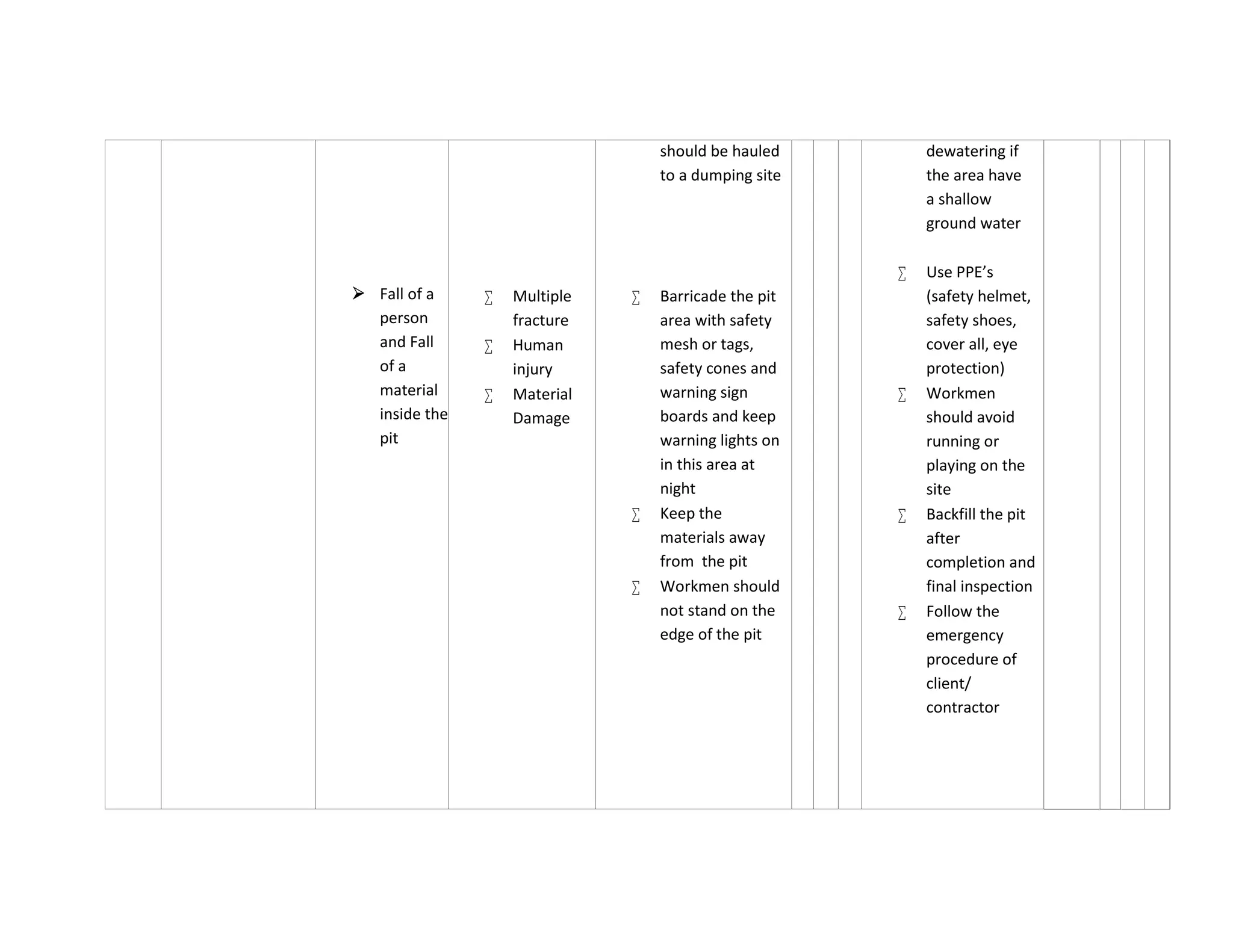

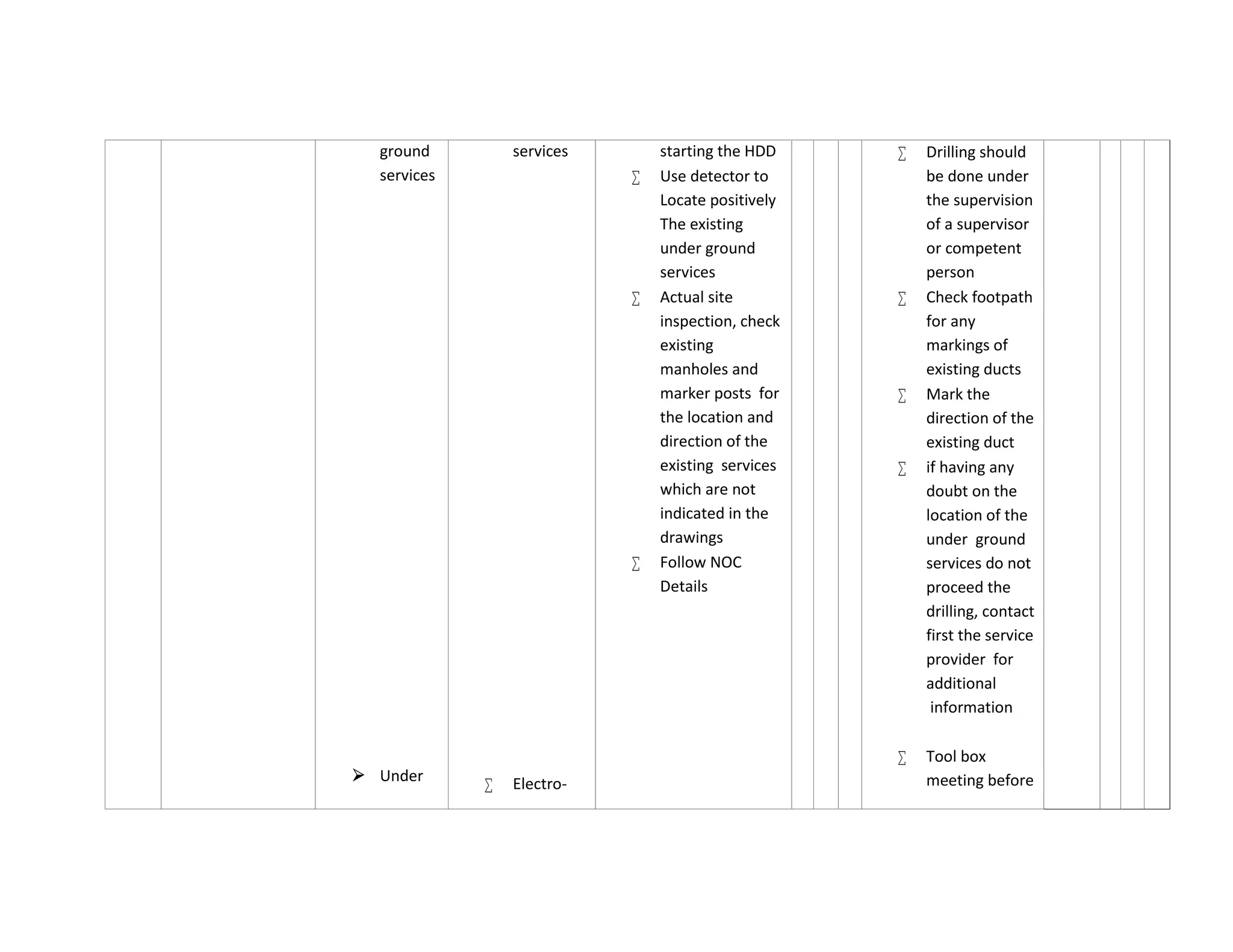

This risk assessment worksheet evaluates the risks associated with a horizontal directional drilling project for a housing expansion project. It identifies 4 main tasks - site survey, trial pits and entry/exit pits, horizontal directional drilling, and use of HDD equipment. For each task, it lists potential hazards, consequences, existing controls, additional control measures, responsibilities, and residual risks. The document is signed by the general manager of Cross Road Drilling and approved by the client.