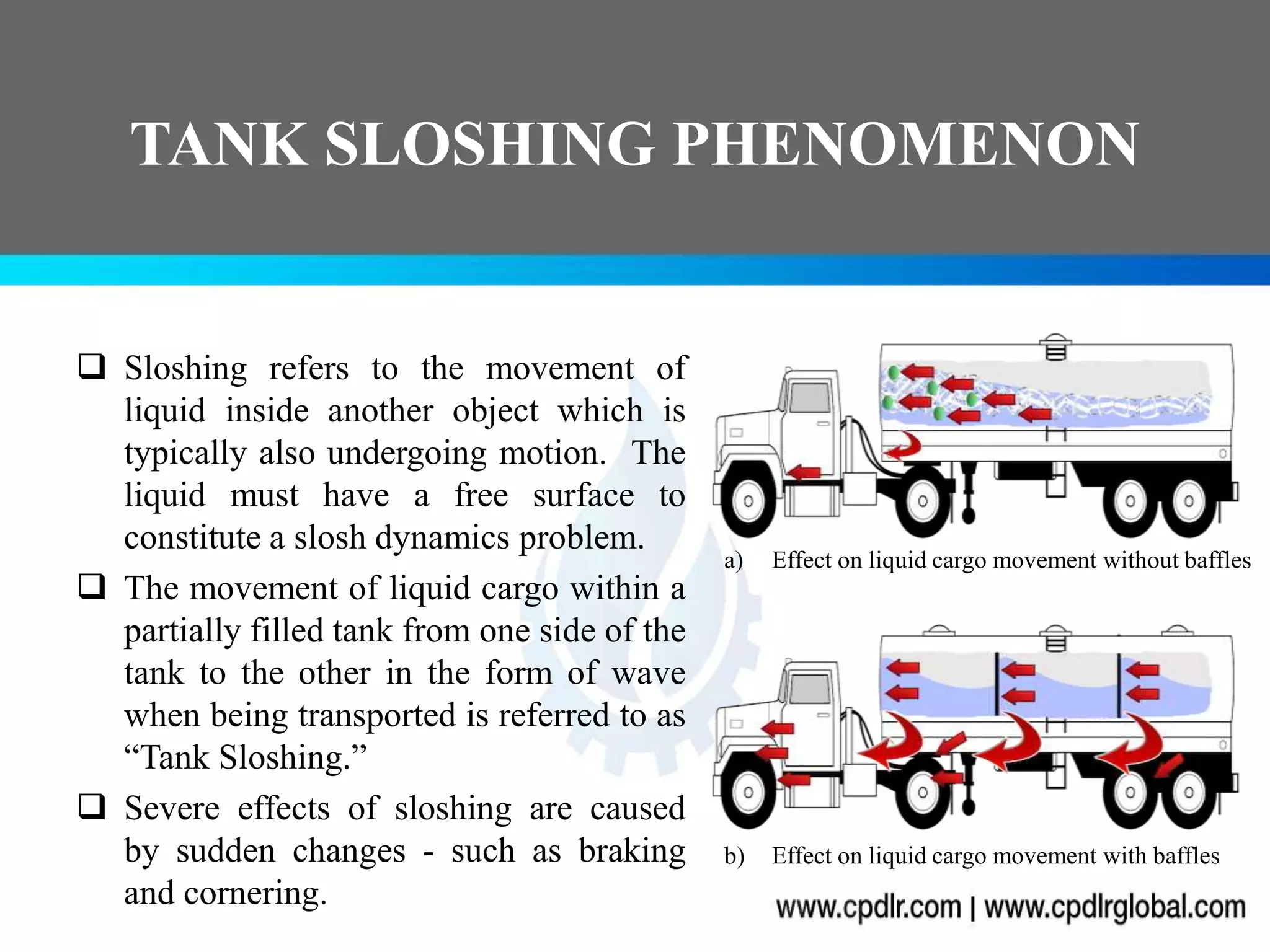

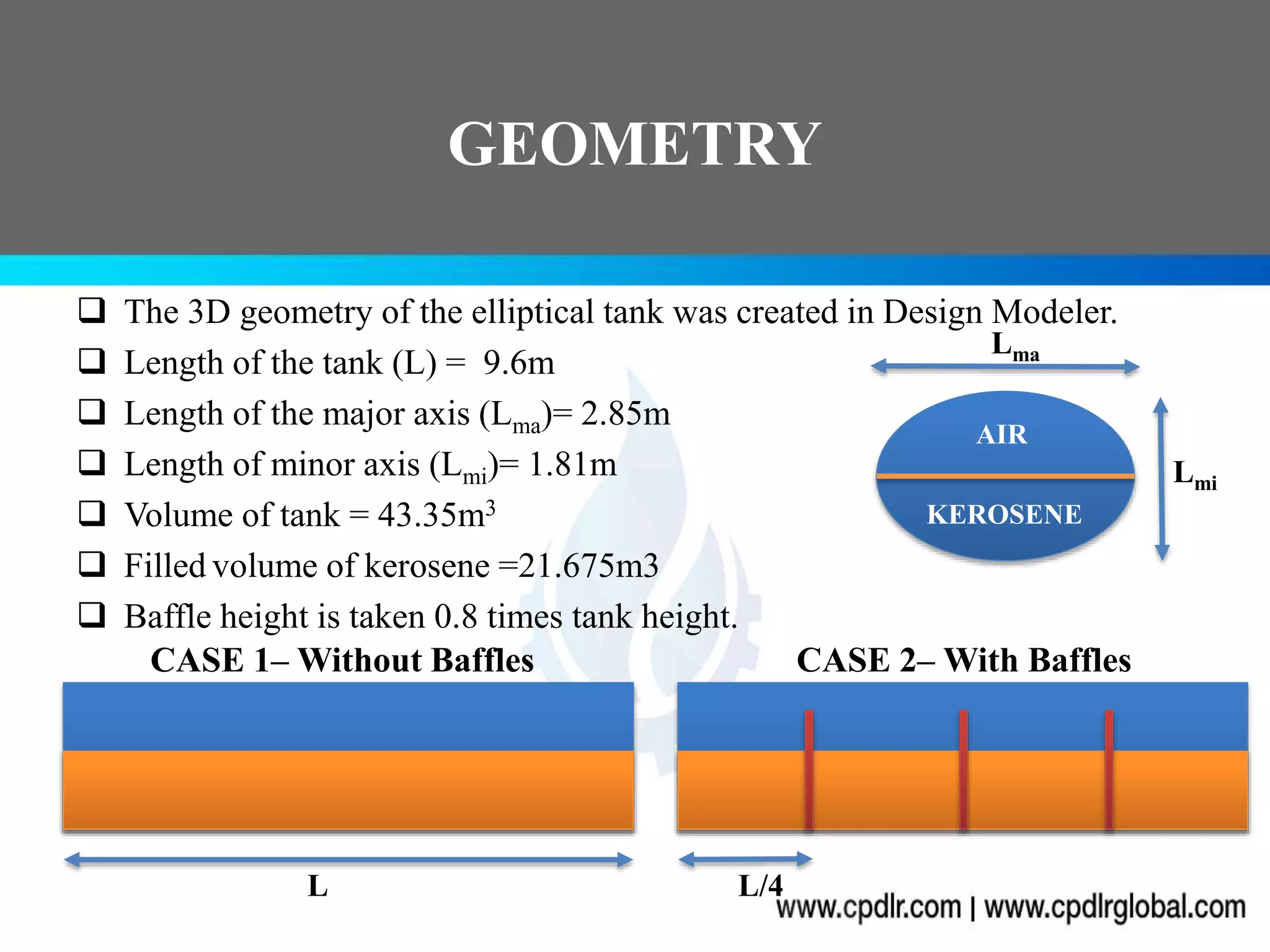

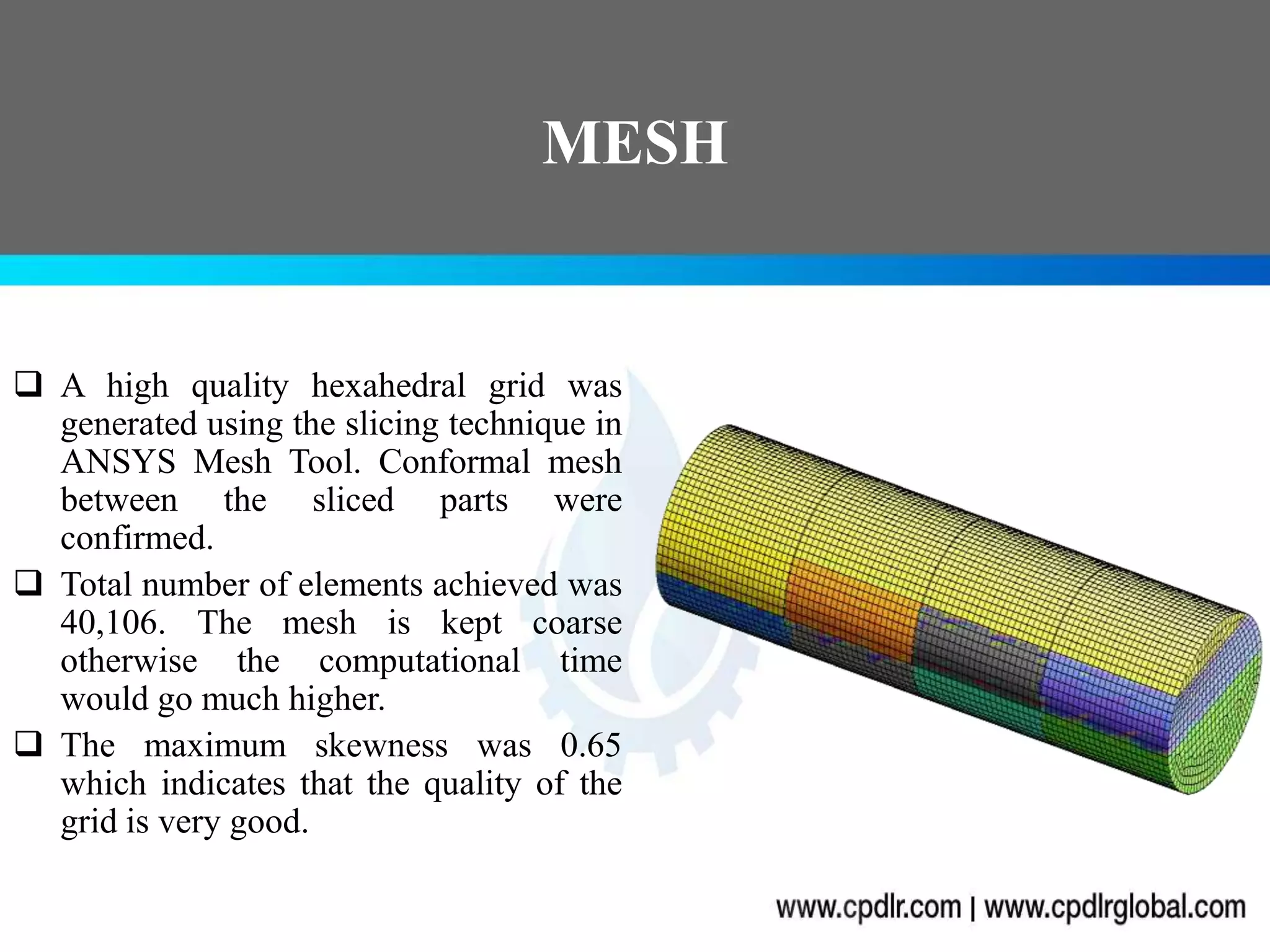

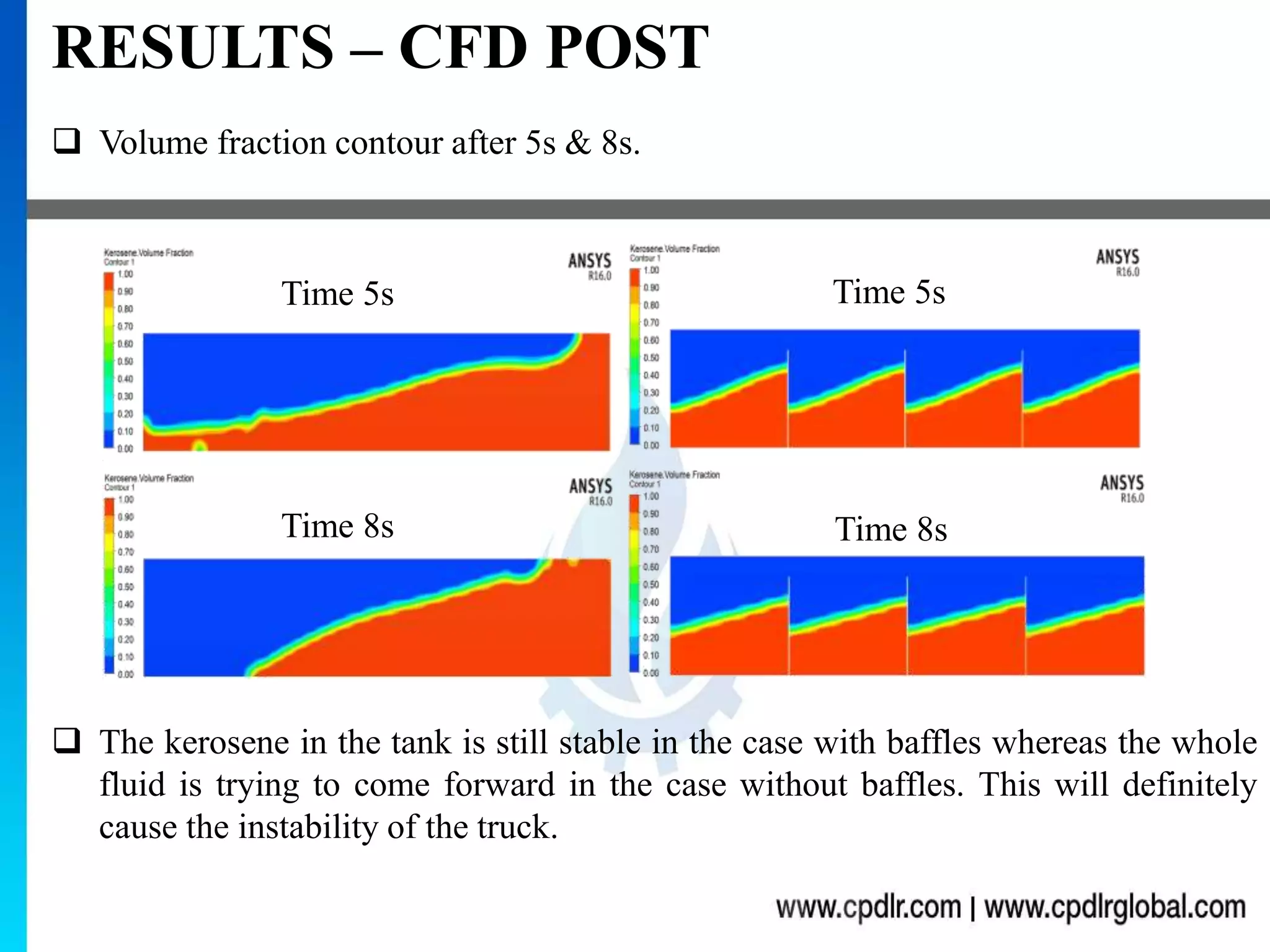

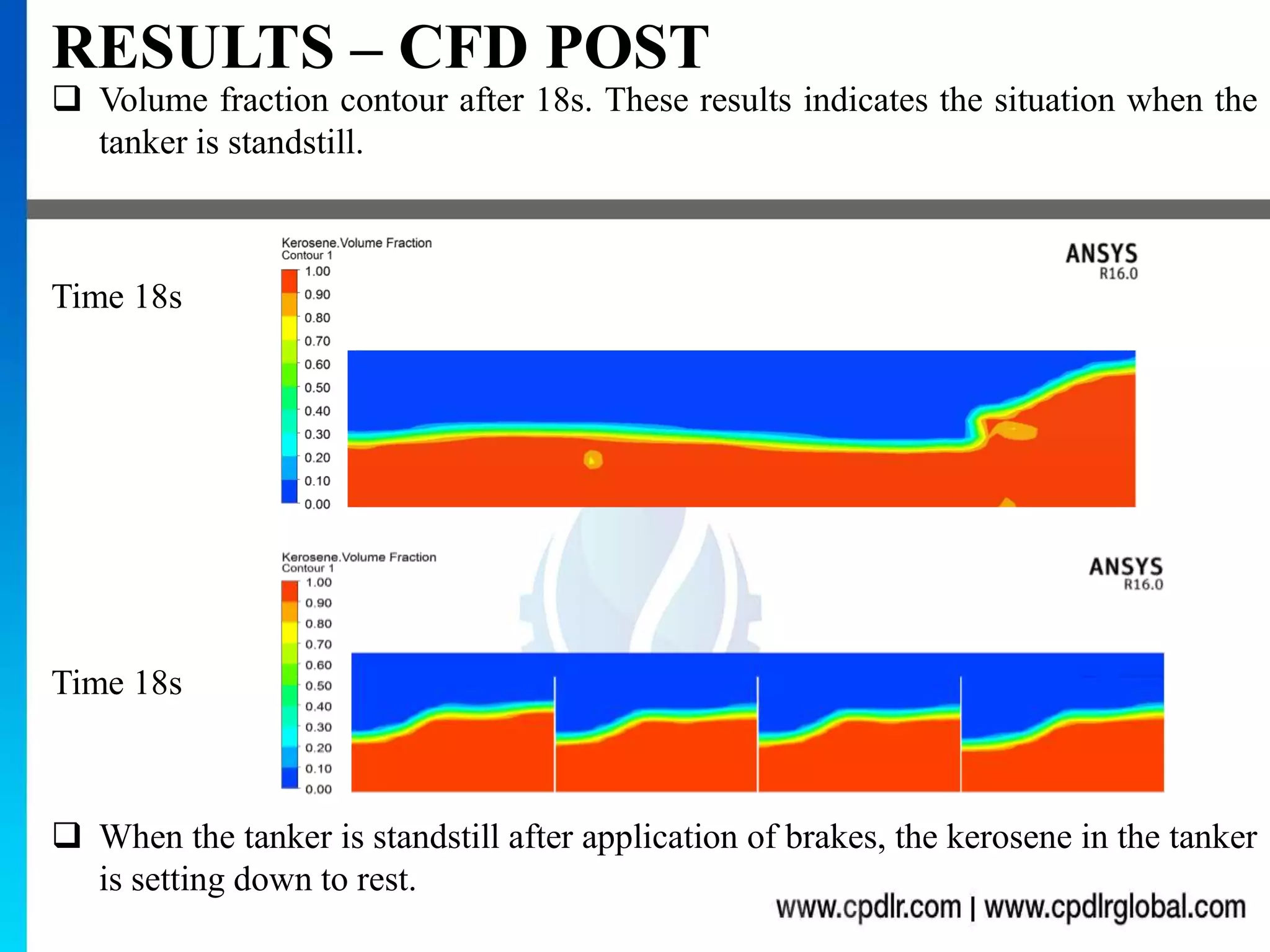

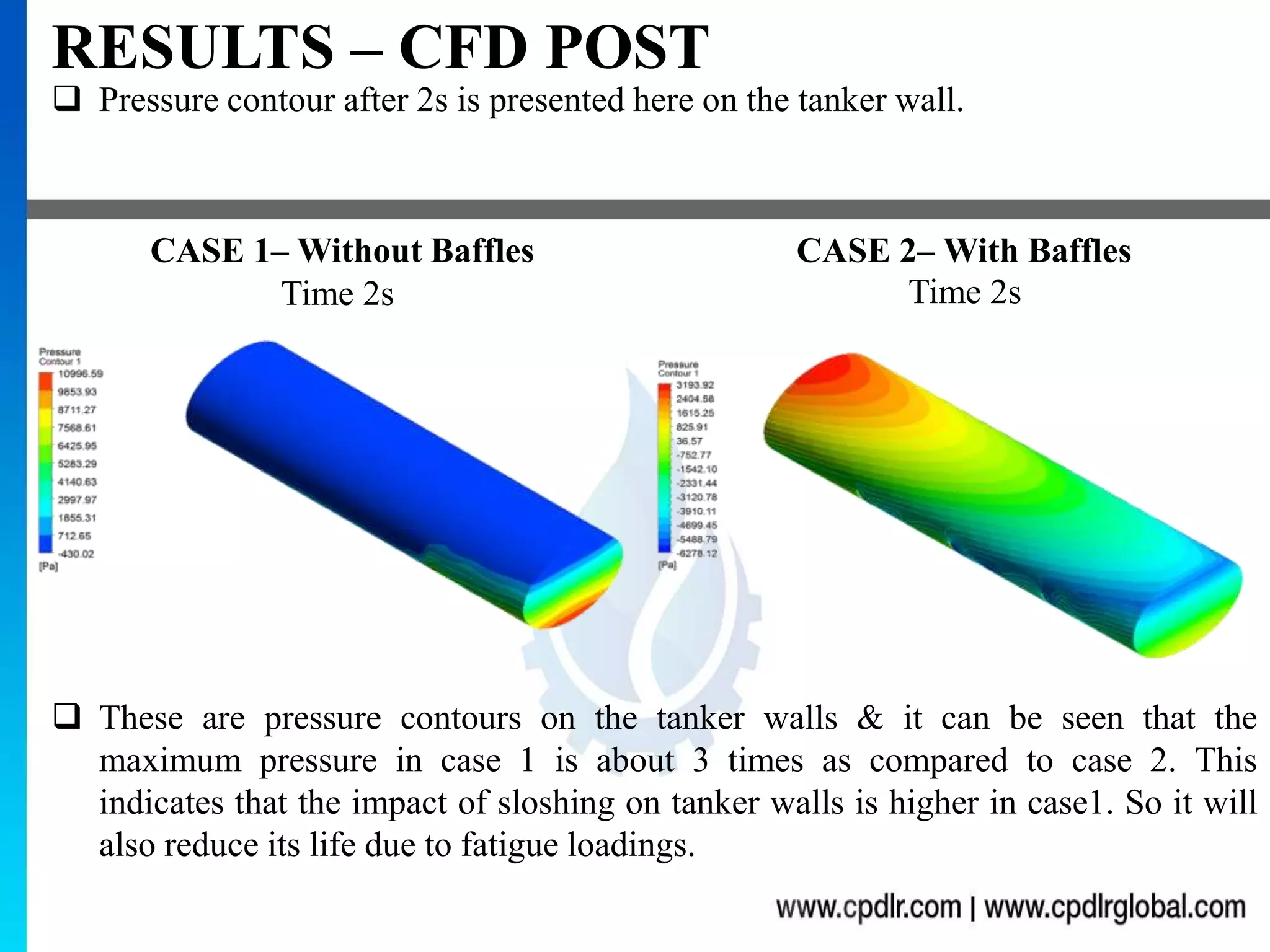

The document discusses a simulation of tank sloshing using the VOF multiphase model in ANSYS Fluent, examining the effects of liquid cargo movement in tanks with and without baffles. Results indicate that the presence of baffles significantly stabilizes the liquid, reducing the risk of rollover and maintaining safer handling of highway tank vehicles during acceleration and braking. Key findings highlight the increase in pressure and instability in tanks without baffles, suggesting that proper baffle design is essential for enhancing safety.