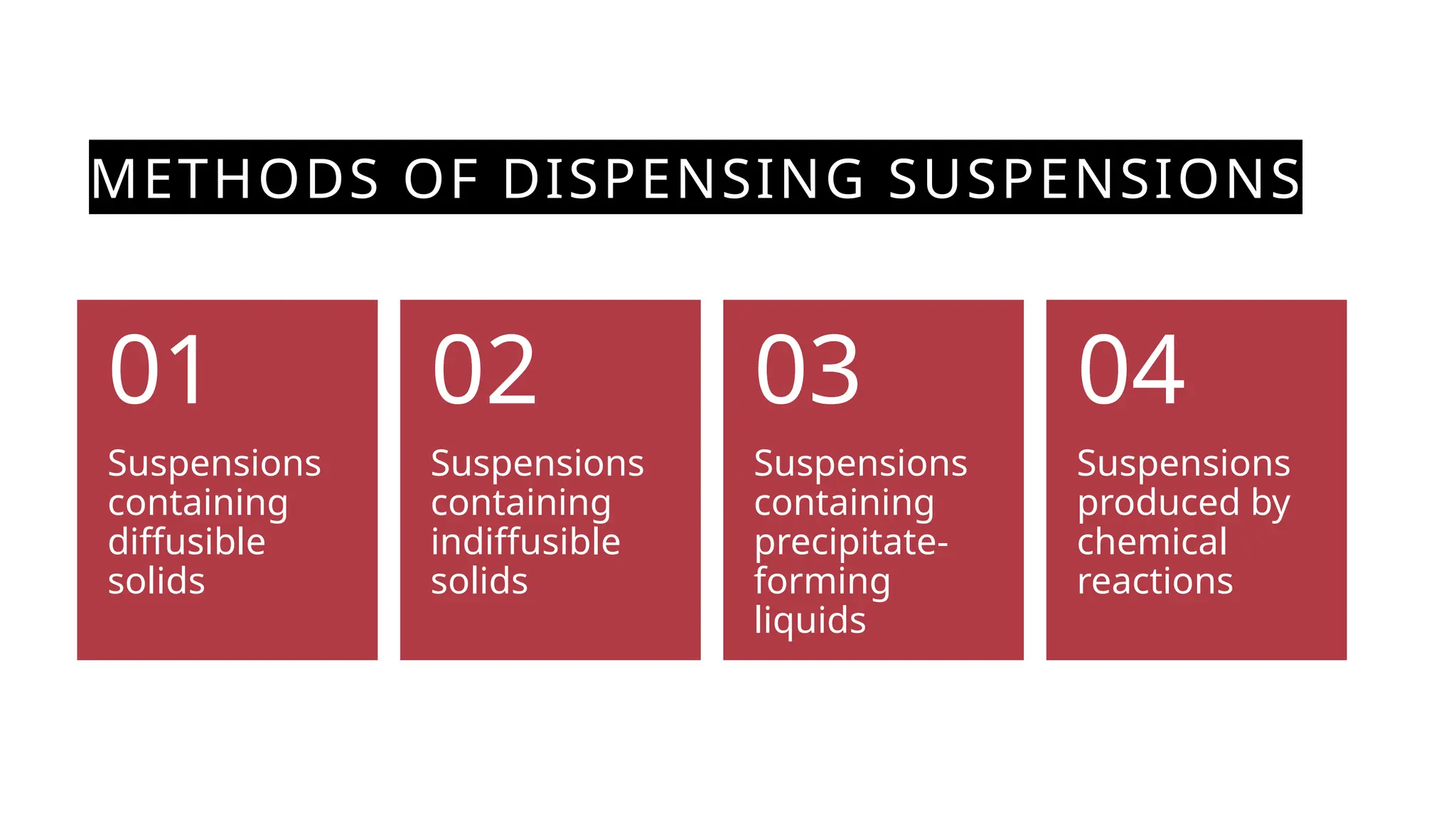

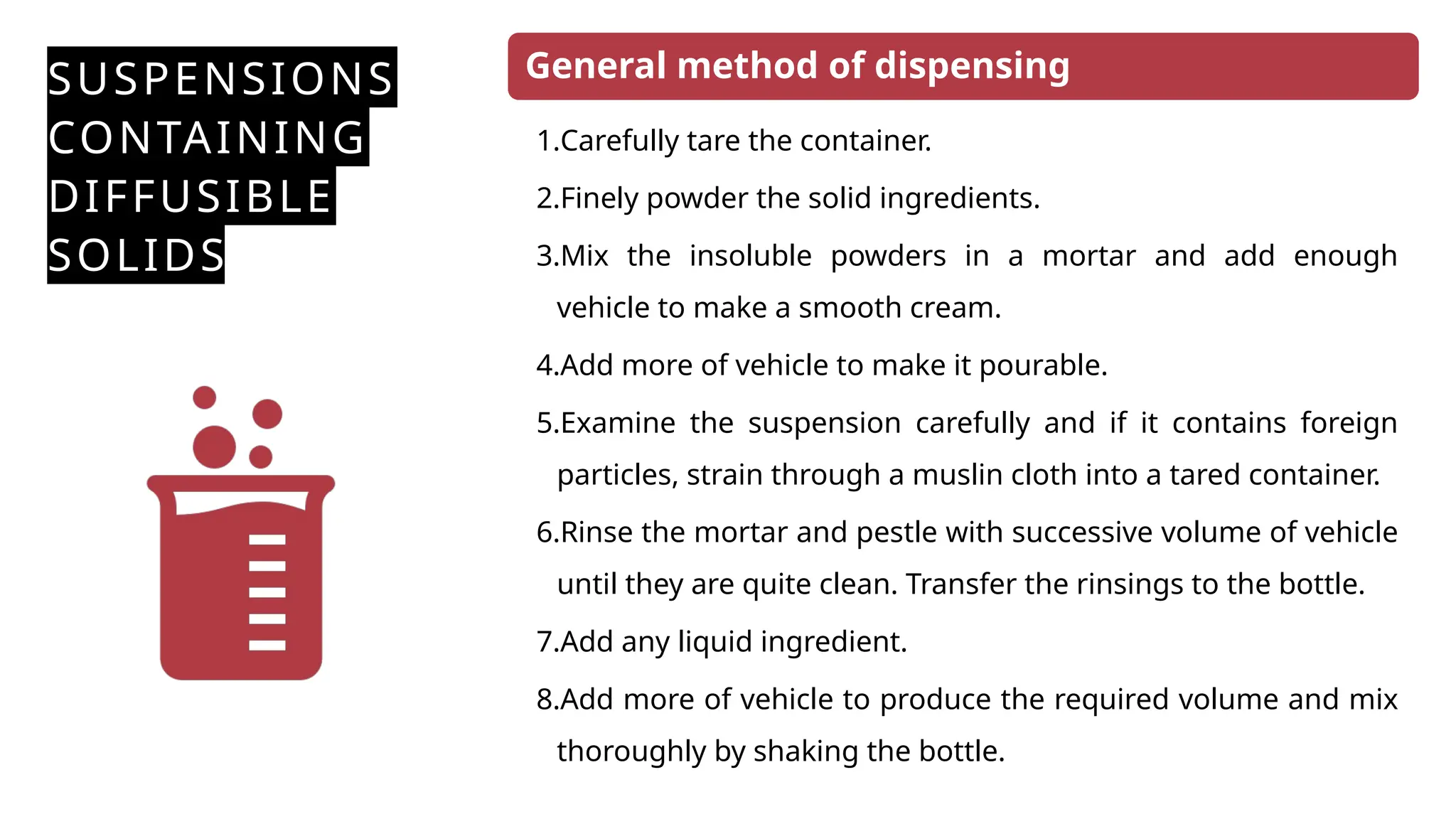

The document outlines methods for dispensing various types of suspensions, including those containing diffusible and indiffusible solids, precipitate-forming liquids, and those produced by chemical reactions. It details specific steps for preparation and techniques to prevent stability issues such as sedimentation, flocculation, and viscosity changes. Additionally, it discusses the importance of appropriate containers, labeling, and storage conditions for suspension products.