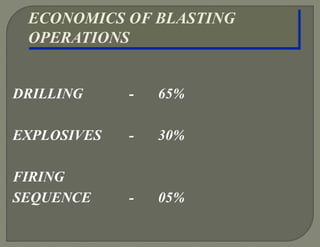

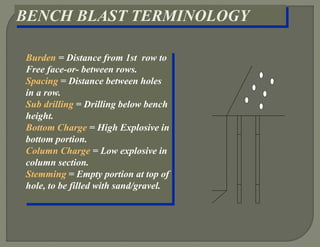

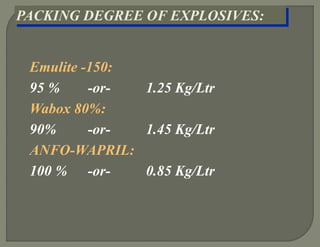

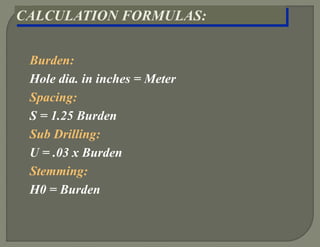

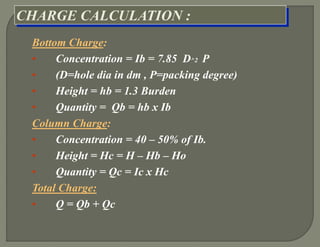

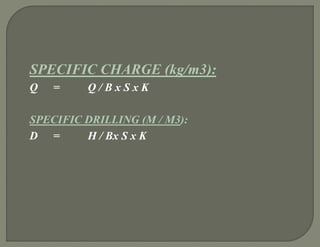

The document discusses drilling and blasting operations for mining. It explains that drilling accounts for 65% of blasting costs while explosives account for 30%. It describes factors to consider for drilling like depth and rock properties. There are different types of drills from handheld to track mounted. The document also discusses blast design terminology like burden, spacing, stemming. It provides formulas to calculate burden, spacing, stemming and explosive charge quantities. The goal is finer fragmentation with a spacing to burden ratio over 1, delay detonators and higher explosive charge.