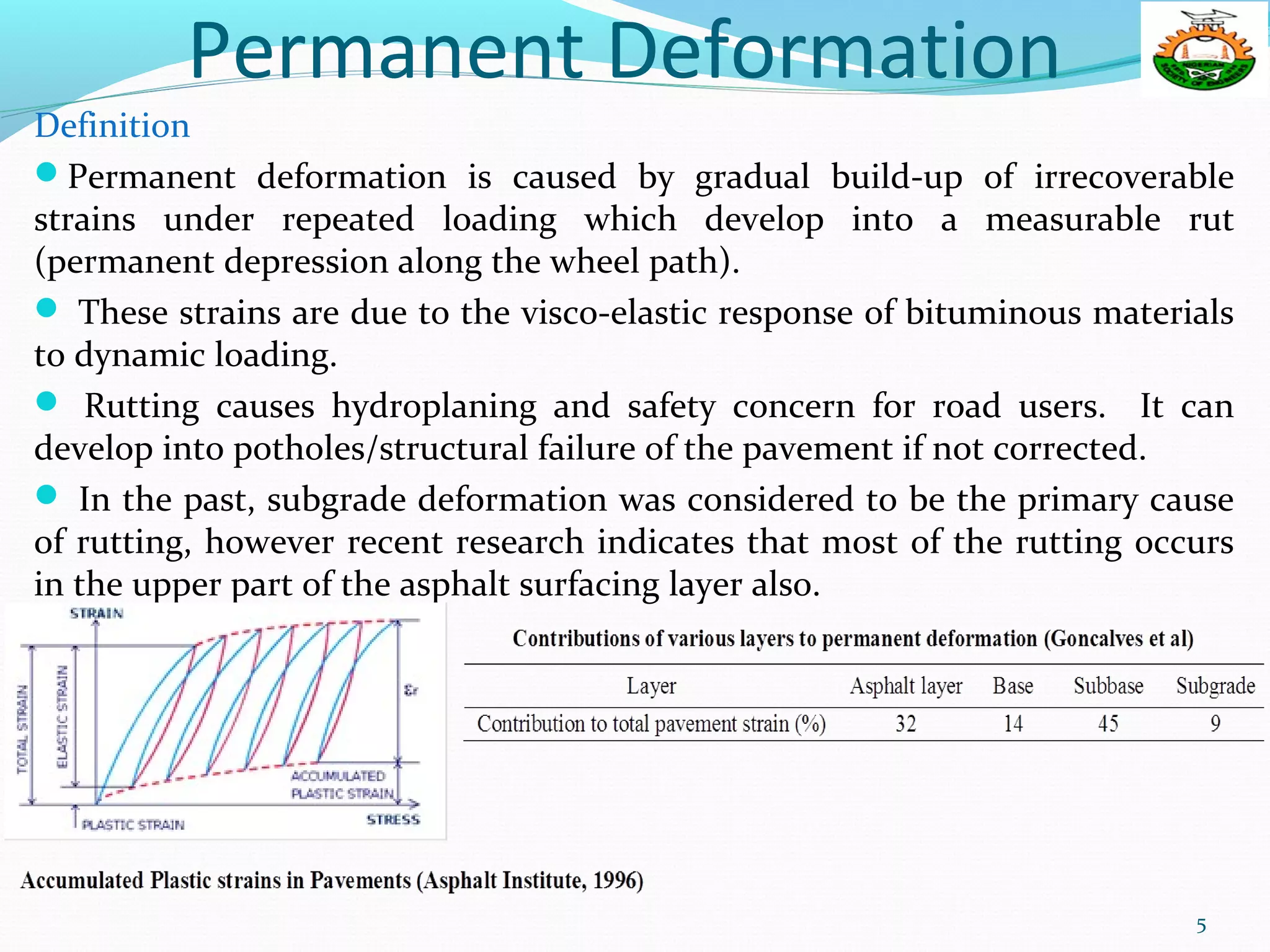

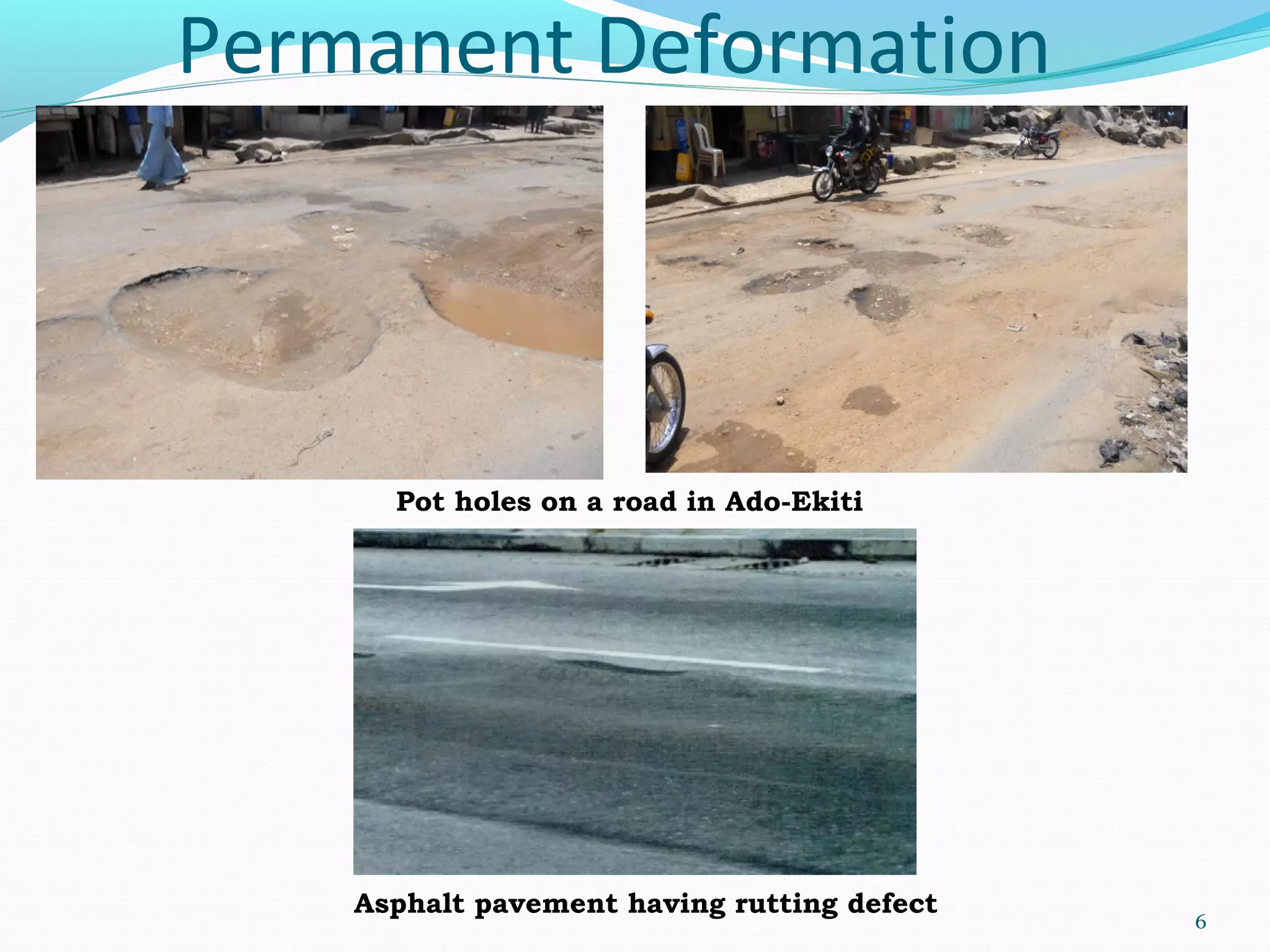

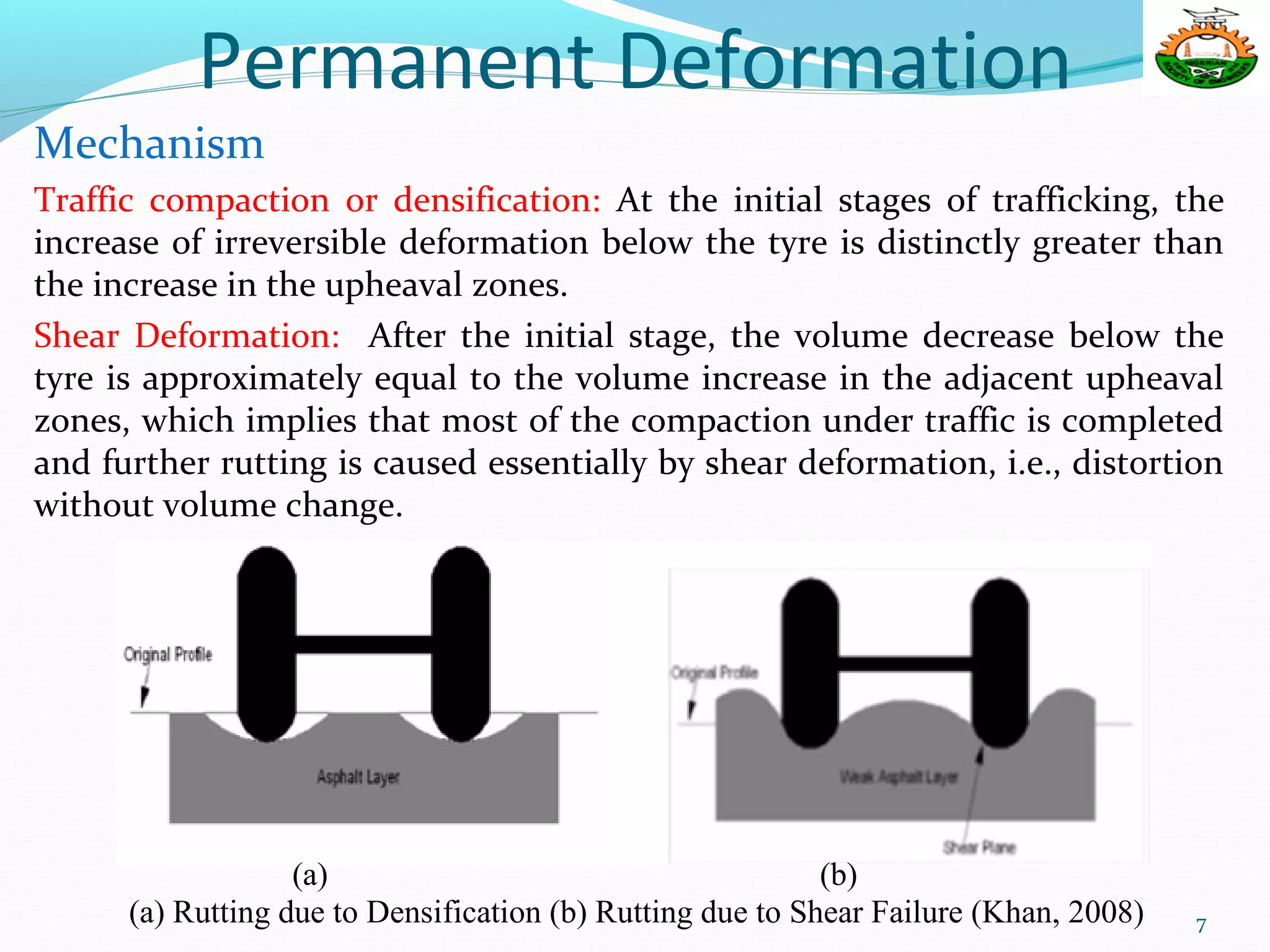

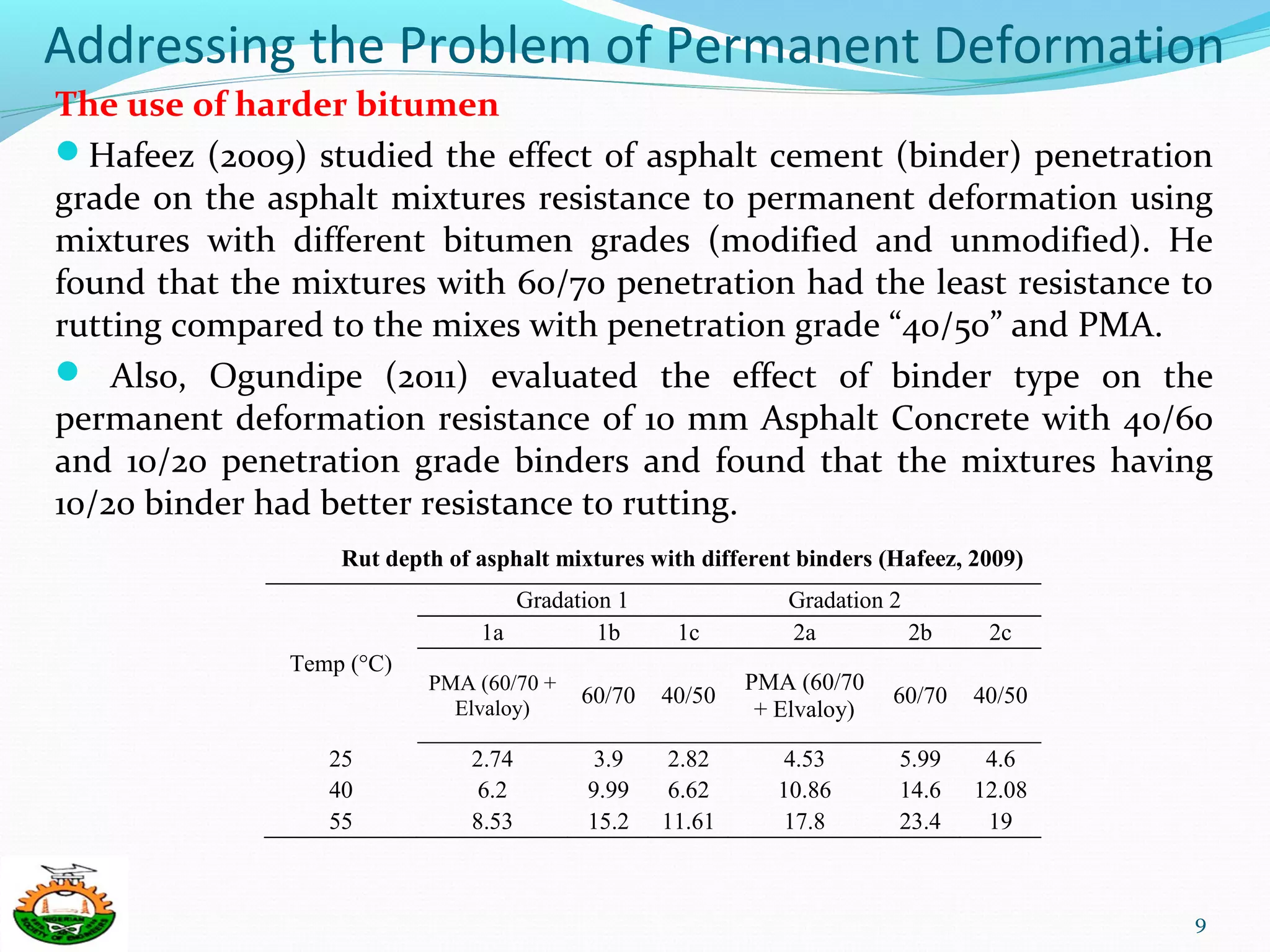

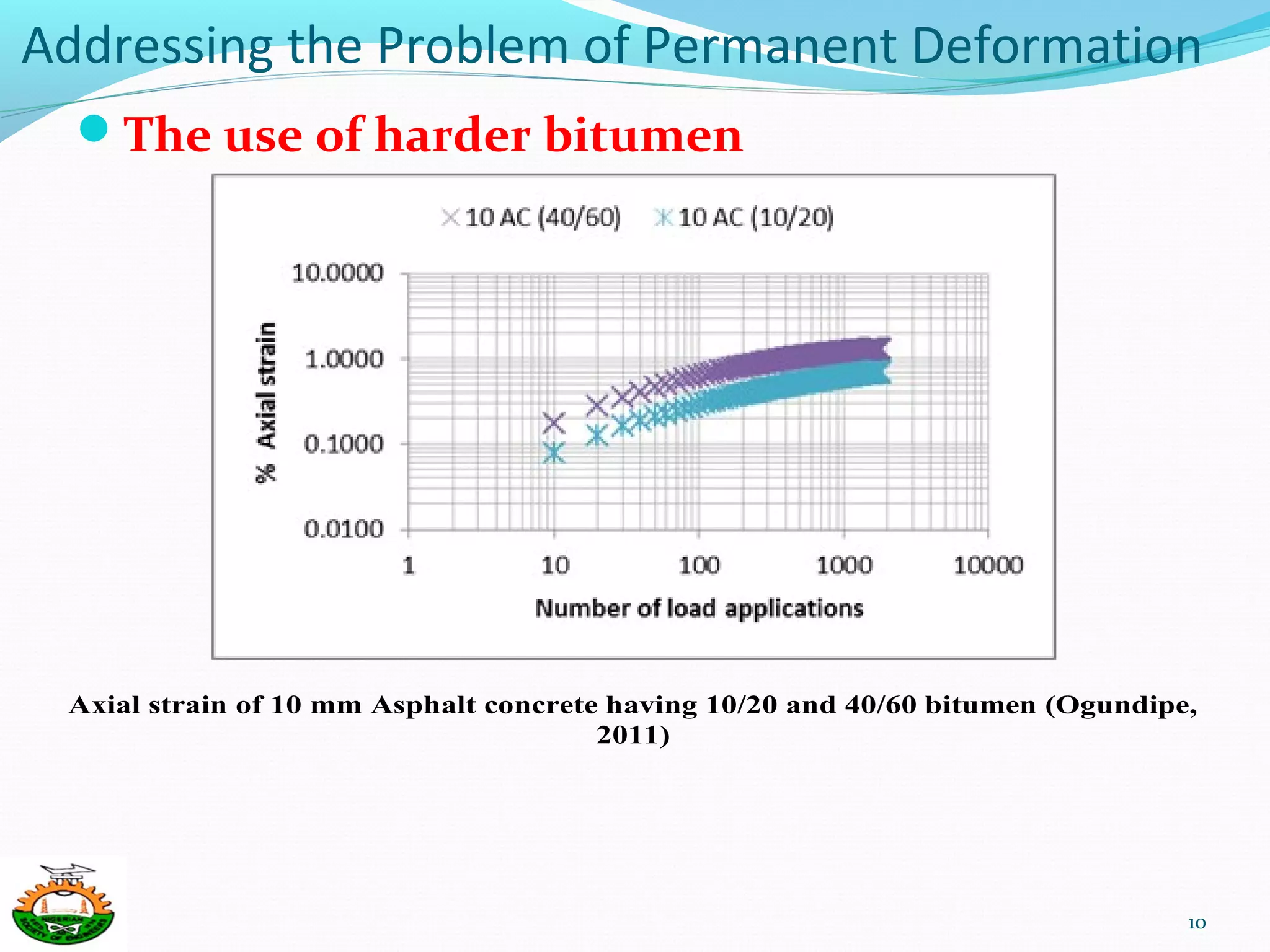

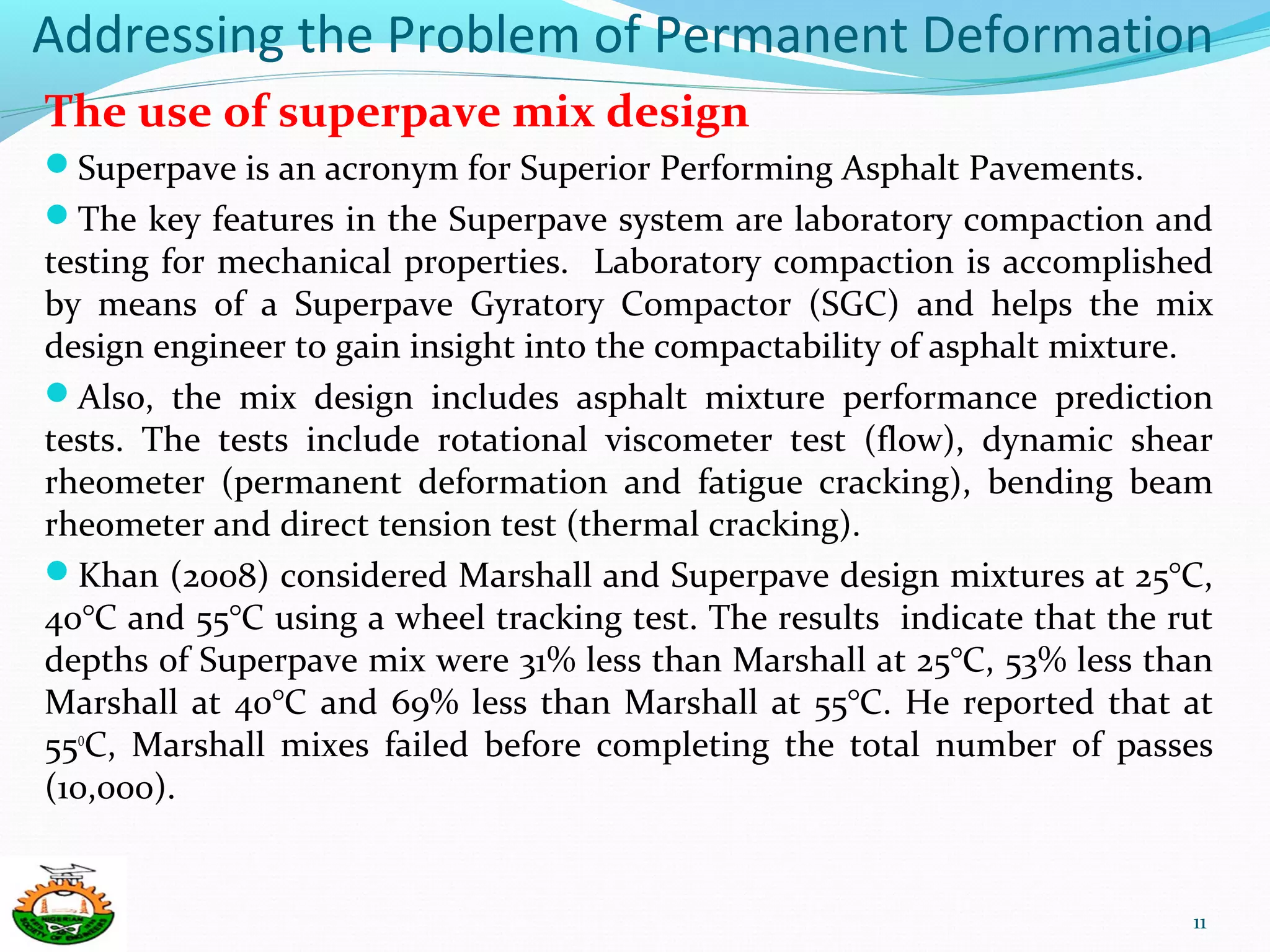

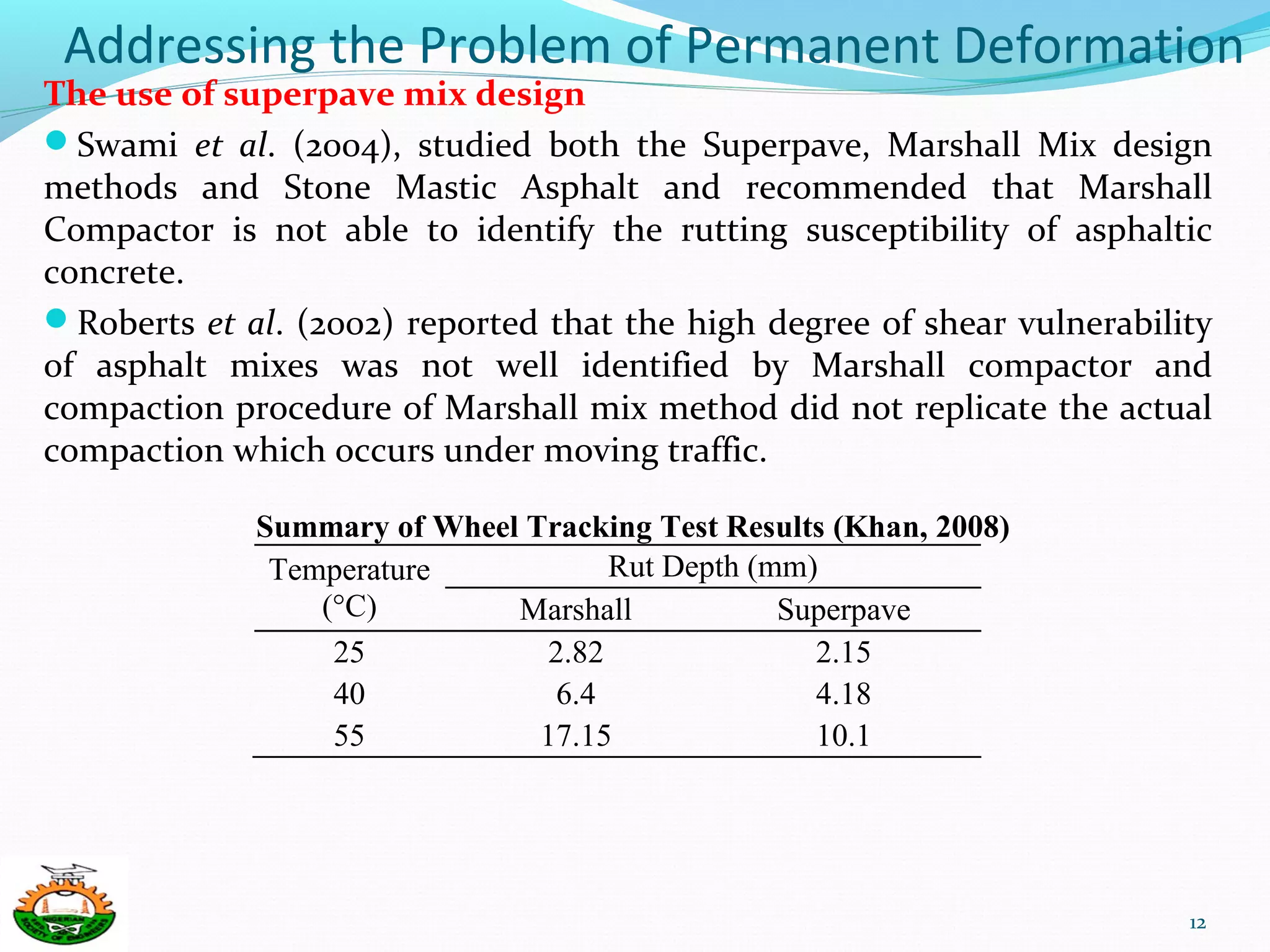

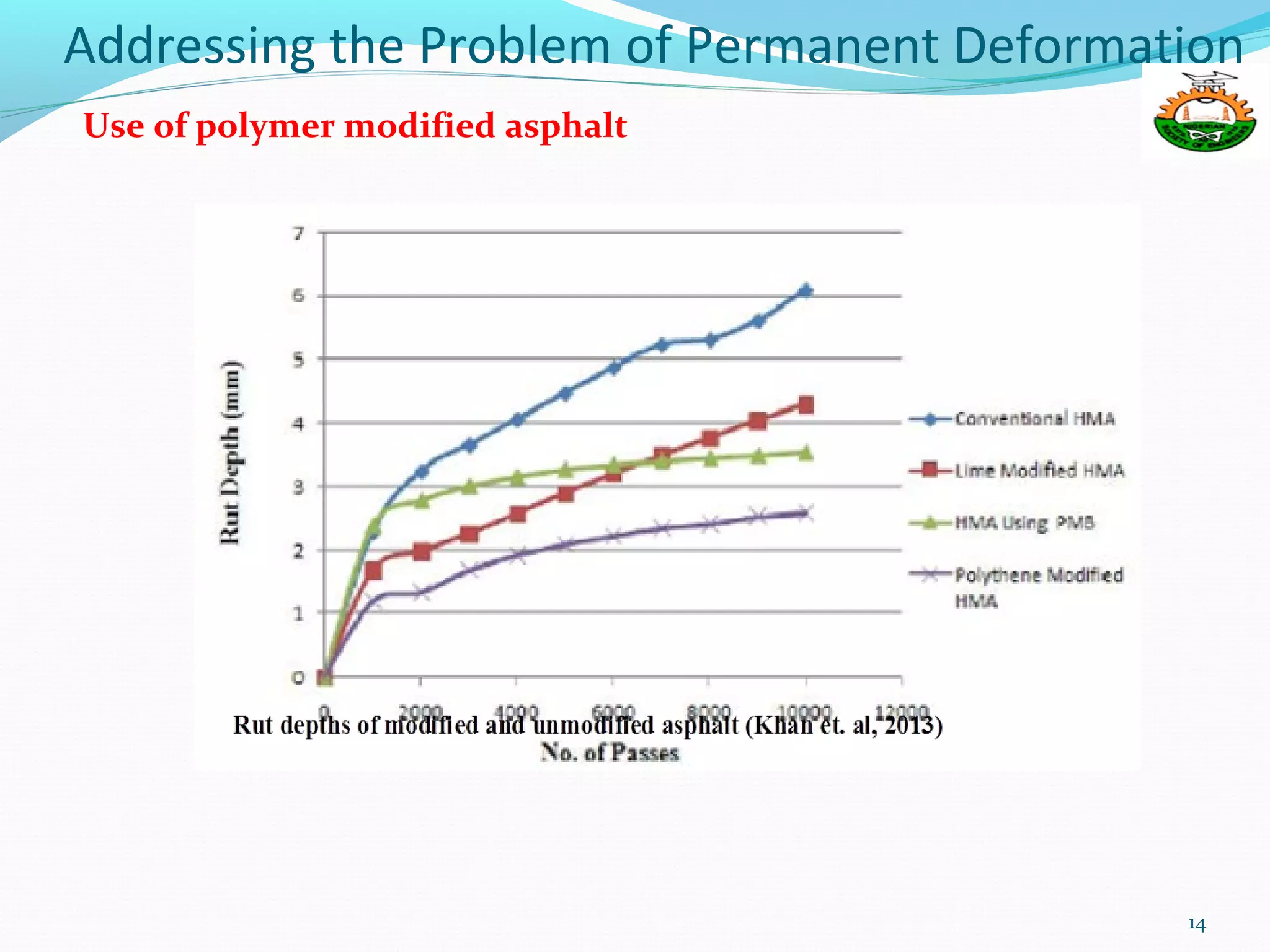

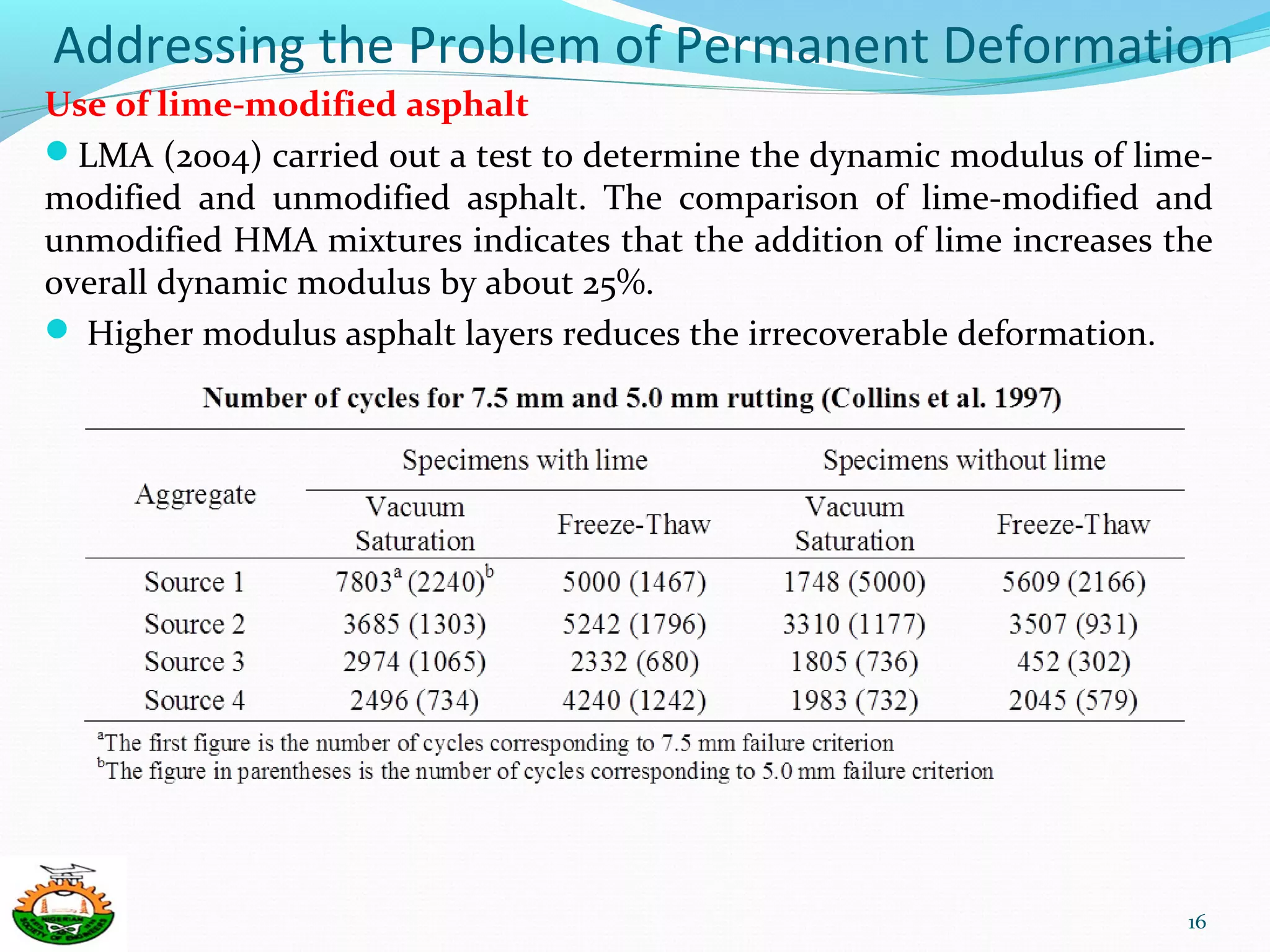

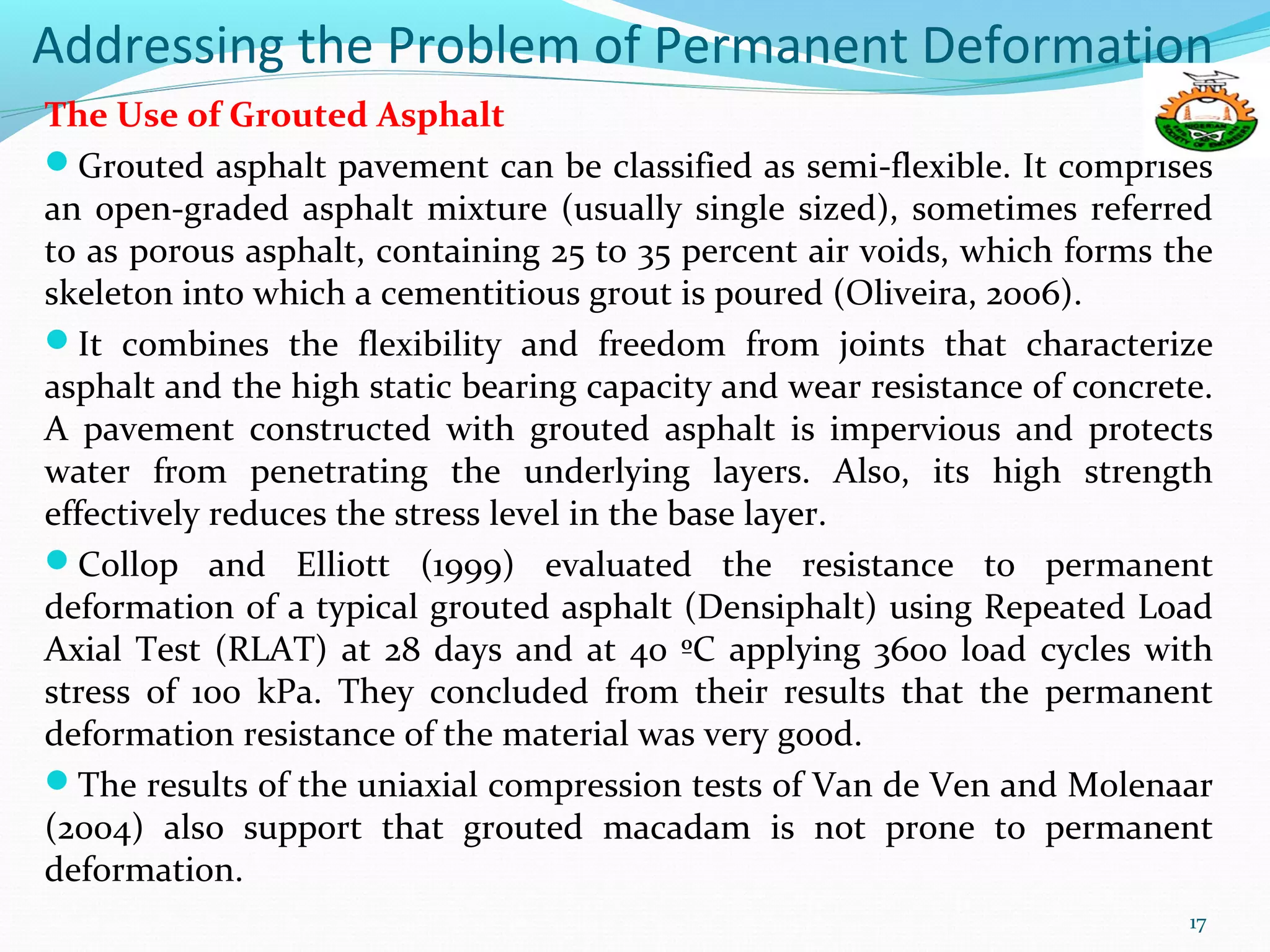

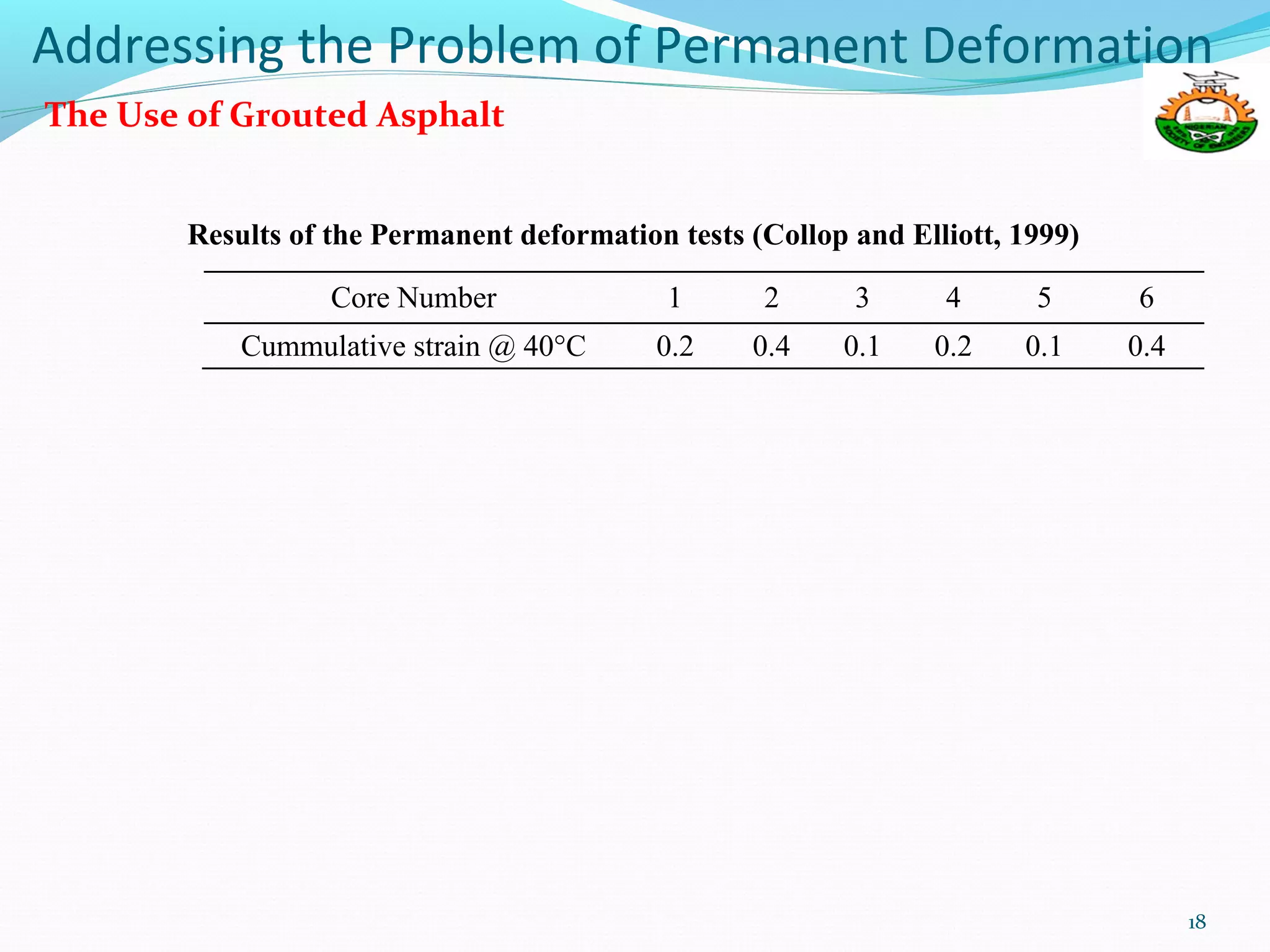

This document summarizes strategies for addressing permanent deformation of road pavements in Nigeria. It discusses how permanent deformation occurs due to densification and shear under repeated traffic loading. Common causes are weak asphalt mixtures and subgrades. Solutions proposed include using harder bitumen binders, the Superpave mix design method, polymer-modified asphalt, lime-modified asphalt, grouted asphalt, and standardized tests like the repeated load axial test and wheel tracking test. Adopting improved materials and designs, along with supporting research and policies, could help ensure more sustainable road infrastructure in Nigeria.