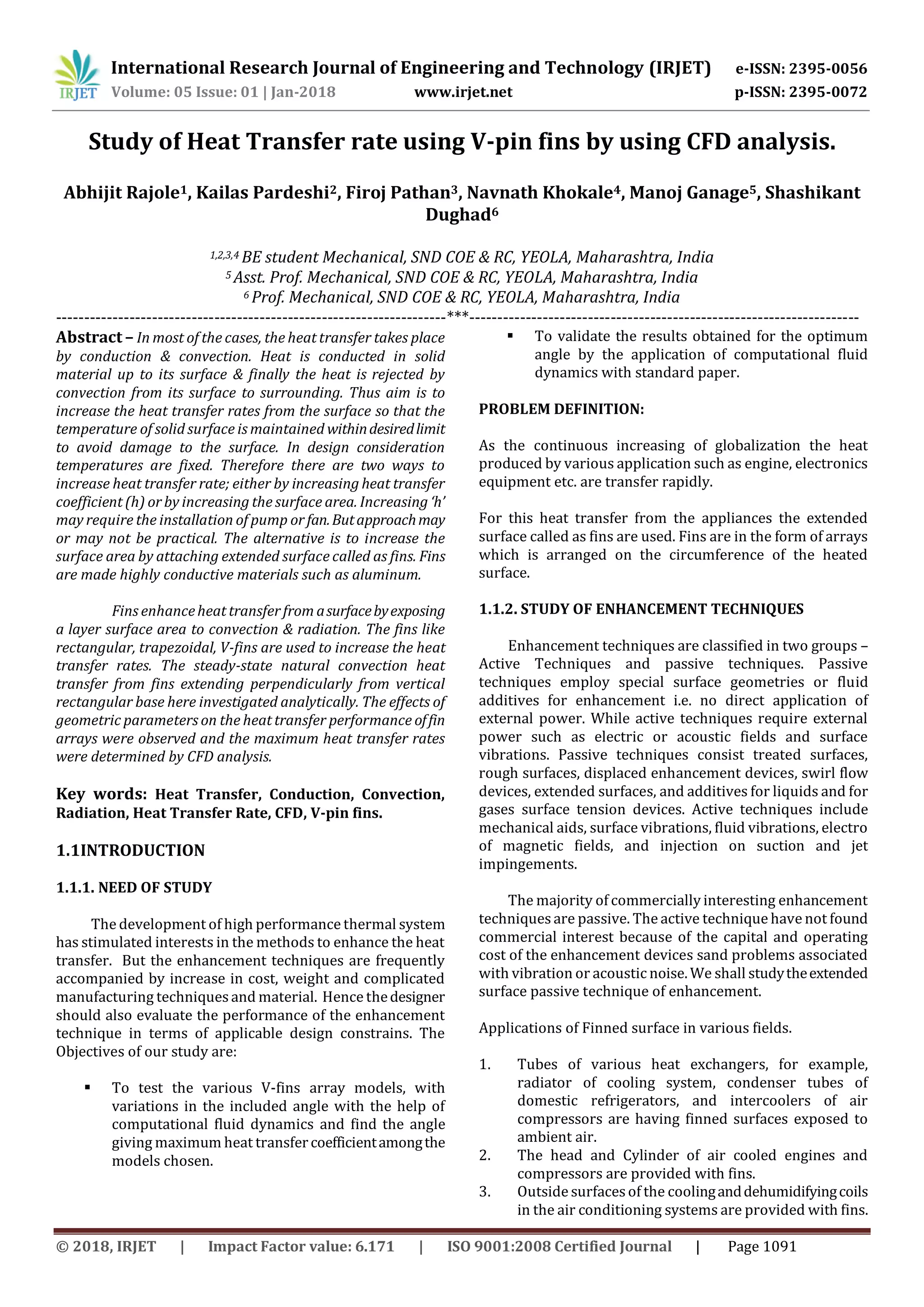

This document summarizes a study that uses computational fluid dynamics (CFD) to analyze heat transfer rates from V-pin fins. The study aims to test different V-fin array models with varying included angles and determine the angle that provides the maximum heat transfer coefficient. The results will be validated against existing literature. CFD is used to obtain discrete solutions to the governing equations for fluid flow and heat transfer around the fin arrays to predict velocity, temperature and heat transfer rate.