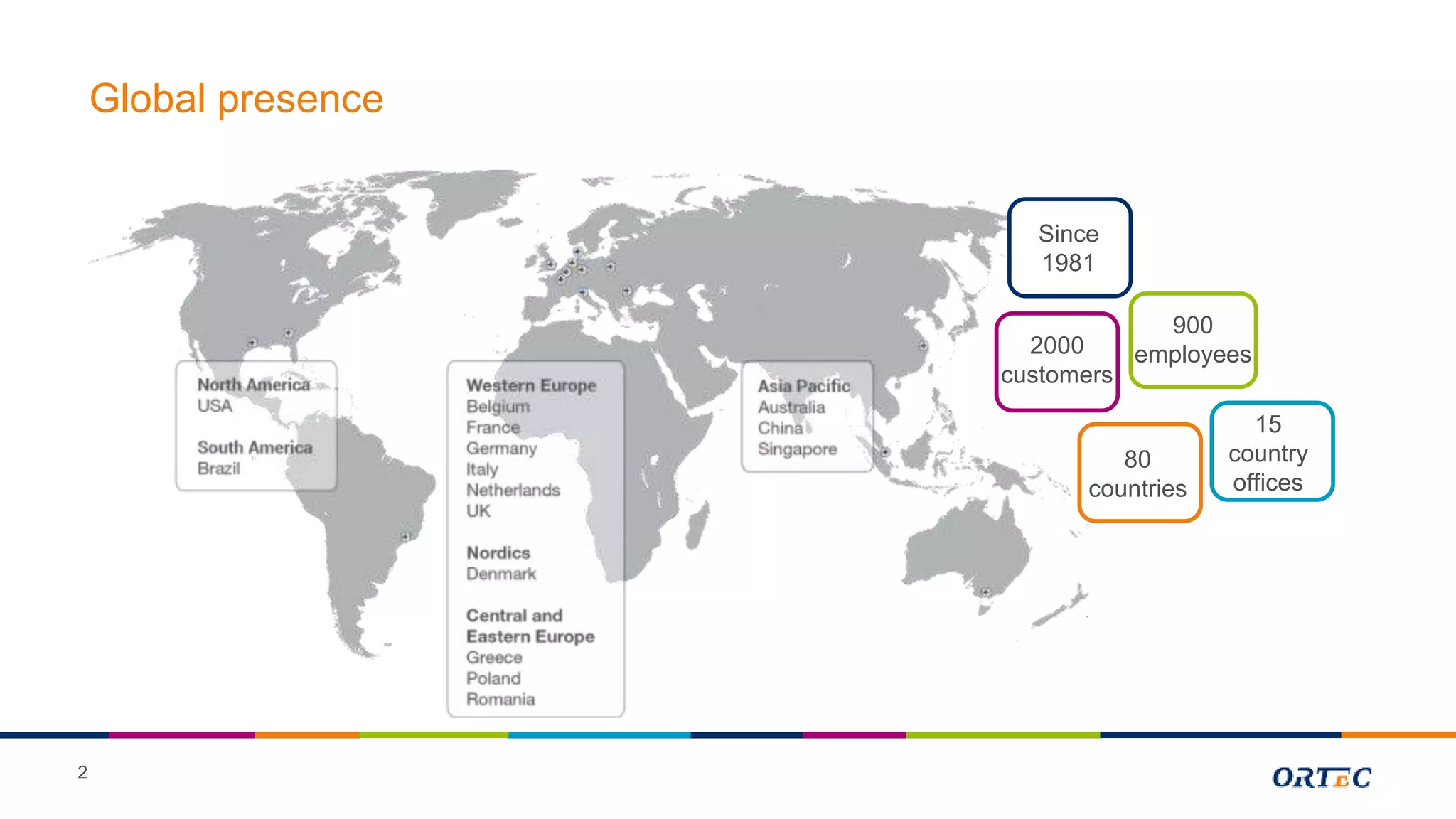

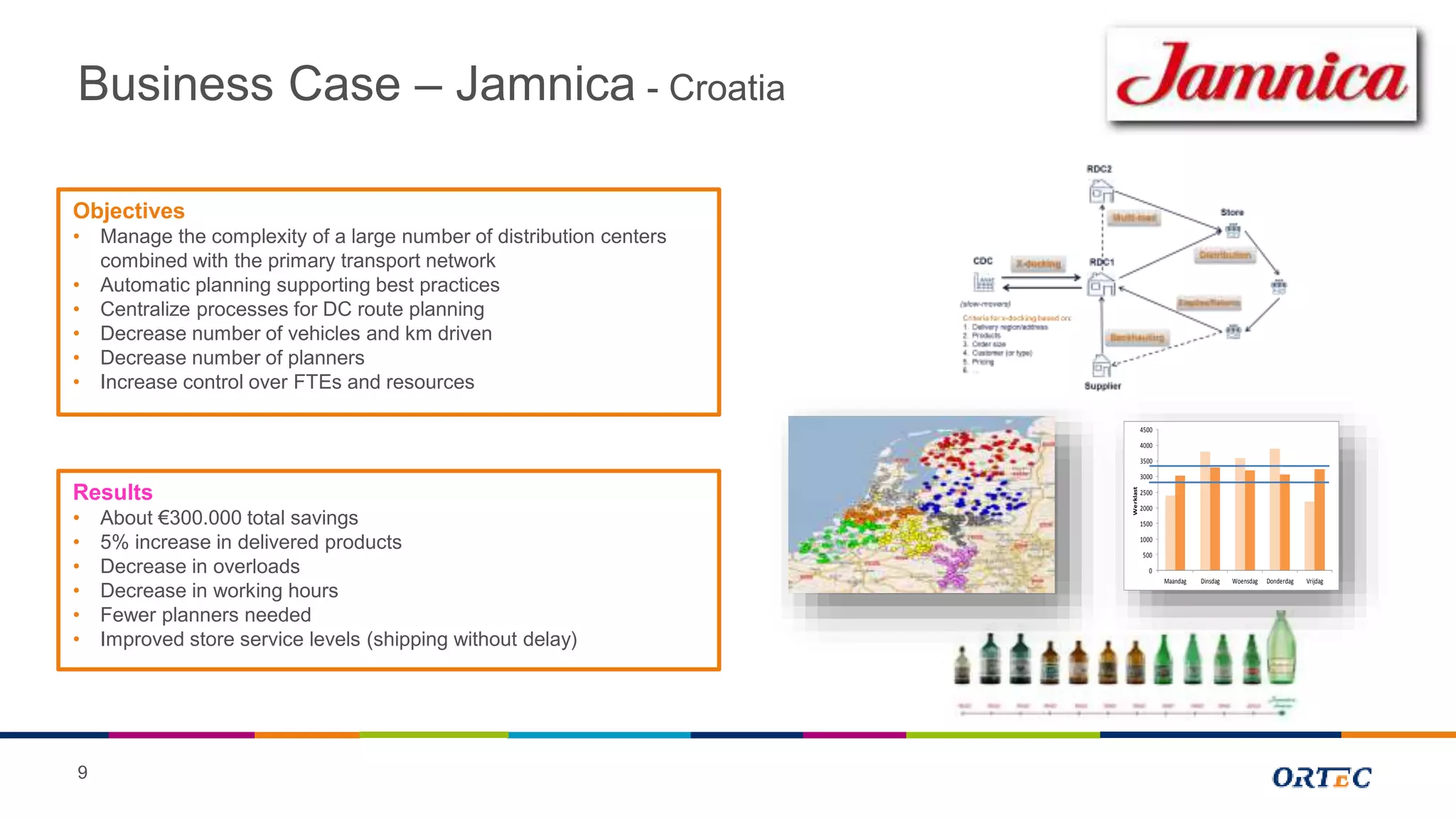

This document discusses how ORTEC provides supply chain optimization solutions to help streamline operations. It outlines ORTEC's global presence and industries served. ORTEC offers planning solutions at the strategic, tactical, and operational levels to optimize networks, resources, and real-time execution. Case studies demonstrate how ORTEC has helped customers like INA and Delhaize reduce costs, improve service quality and flexibility, and gain operational visibility and control through routing, loading, warehouse, workforce, and field service optimization.