This document is a project report submitted by Anurag Kumar Jha to fulfill the requirements of a Bachelor of Technology degree in Mining Engineering from the Indian Institute of Engineering Science and Technology, Shibpur. The project focuses on optimizing stope boundaries in underground mines. It discusses the need for optimization algorithms in mining. It will formulate the optimization problem and develop an economic block model. Experiments will be conducted to evaluate equivalent grade, calculate block economic values, and develop an algorithm to determine the optimum stope position. The goal is to maximize total economic value by selecting blocks for the final mine layout subject to mining constraints and economic parameters.

![27

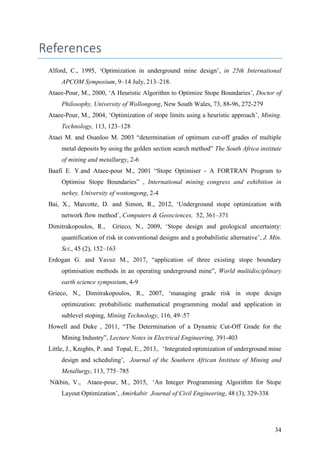

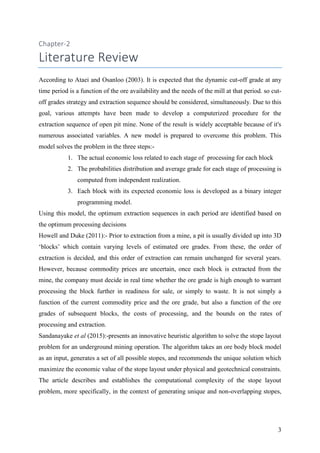

v. Input the grade associated with each block in the matrix to find out the BEV using the

formula:-

vi. Input the dimension of the window encompassing the required number of blocks which

have to be analysed in each iteration for the total cost.

vii. Let,

R = No. of rows of the matrix

C = No. of column of the matrix

r = No. of rows of the stope

c = No. of columns of the stope

viii. Let,

Maximum sum of the stope economic value = -∞

Maximum sum stope row number = 1

Maximum sum stope column number = 1

for i=1 to R-r+1 do

for j=1 to C-c+1 do

sum = 0

for i’=i to i+r-1 do

for j’=j to j+c-1 do

sum = sum + mat[i’][j’]

end

end

if sum > maximum sum of the stope economic value do

maximum sum of the stope economic value = sum

maximum sum stope row No. = i

maximum sum stope column No. =j

end

end

end](https://image.slidesharecdn.com/finalyearprojecta-180516202510/85/Stope-Optimization-in-Metal-Mines-36-320.jpg)

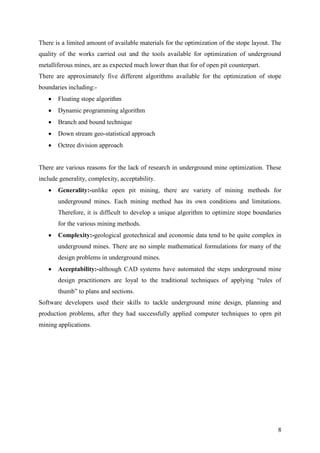

![31

Figure-4.3 Flow chart

i’<=i+r-1

Initialise j’=j

j’<=j+c-1

Sum = sum + mat [i’][j’]

j’++

end for

i’++

end for

Sum >maximum

sum stope value

.

Maximum sum stope value =sum

Maximum sum stope row number = i

Maximum sum stope column = j

end for

end for

End

false

false

true

true

False

true](https://image.slidesharecdn.com/finalyearprojecta-180516202510/85/Stope-Optimization-in-Metal-Mines-40-320.jpg)