Stephen Hufford Resume

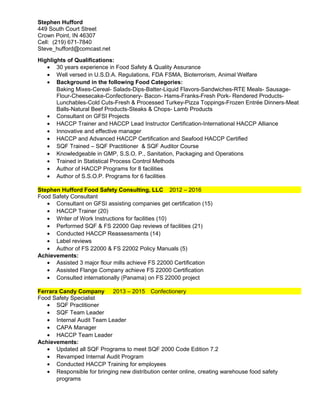

- 1. Stephen Hufford 449 South Court Street Crown Point, IN 46307 Cell: (219) 671-7840 Steve_hufford@comcast.net Highlights of Qualifications: • 30 years experience in Food Safety & Quality Assurance • Well versed in U.S.D.A. Regulations, FDA FSMA, Bioterrorism, Animal Welfare • Background in the following Food Categories: Baking Mixes-Cereal- Salads-Dips-Batter-Liquid Flavors-Sandwiches-RTE Meals- Sausage- Flour-Cheesecake-Confectionery- Bacon- Hams-Franks-Fresh Pork- Rendered Products- Lunchables-Cold Cuts-Fresh & Processed Turkey-Pizza Toppings-Frozen Entrée Dinners-Meat Balls-Natural Beef Products-Steaks & Chops- Lamb Products • Consultant on GFSI Projects • HACCP Trainer and HACCP Lead Instructor Certification-International HACCP Alliance • Innovative and effective manager • HACCP and Advanced HACCP Certification and Seafood HACCP Certified • SQF Trained – SQF Practitioner & SQF Auditor Course • Knowledgeable in GMP, S.S.O. P., Sanitation, Packaging and Operations • Trained in Statistical Process Control Methods • Author of HACCP Programs for 8 facilities • Author of S.S.O.P. Programs for 6 facilities Stephen Hufford Food Safety Consulting, LLC 2012 – 2016 Food Safety Consultant • Consultant on GFSI assisting companies get certification (15) • HACCP Trainer (20) • Writer of Work Instructions for facilities (10) • Performed SQF & FS 22000 Gap reviews of facilities (21) • Conducted HACCP Reassessments (14) • Label reviews • Author of FS 22000 & FS 22002 Policy Manuals (5) Achievements: • Assisted 3 major flour mills achieve FS 22000 Certification • Assisted Flange Company achieve FS 22000 Certification • Consulted internationally (Panama) on FS 22000 project Ferrara Candy Company 2013 – 2015 Confectionery Food Safety Specialist • SQF Practitioner • SQF Team Leader • Internal Audit Team Leader • CAPA Manager • HACCP Team Leader Achievements: • Updated all SQF Programs to meet SQF 2000 Code Edition 7.2 • Revamped Internal Audit Program • Conducted HACCP Training for employees • Responsible for bringing new distribution center online, creating warehouse food safety programs

- 2. John Hofmeister & Son 2009 – 2011 Meat Processing Quality Assurance & Food Safety Manager • Managed Sanitation, Food Safety and S.S.O.P. Programs • Supervised Contract & Plant Sanitation Staff and Technicians. • Responsible for Label Approvals & Export Shipments • Trained all company employees in GMP’s, Food Safety, Food Defense, HACCP & Safety Achievements: • Wrote and established Training Program for employees. • Created instrument calibration program • Instituted Monthly Internal Audit system for plant. • Improved plant Silliker rating from Fair (88% prior to arrival) to Excellent (99% in 2011) Stock Yards Packing Company 2008 – 2009 Meat Processing Quality Assurance Manager • Administered and managed HACCP and S.S.O.P. Programs • Supervised Q.A. Technicians and Sanitation Staff. • Worked closely with U.S.D.A. • Responsible for all quality and food safety programs Achievements: • Revised HACCP Program • Rewrote S.S.O.P. Program • Initiated Food Safety Training Program for employees. • Redesigned Plant Sanitation Program • Started environmental testing program • Achieved Superior Rating (highest awarded) from Steritech Audit • Improved and expanded export program including getting the plant certified for shipments to South Korea Stampede Meat, Bridgeview, IL 2006 – 2008 Meat Processing Quality Assurance Manager • Coordinator for Foodservice Customer Relations • Principal liaison with Applebee’s • Wrote product specifications and involved in new product development • Investigated customer issues and handled special projects • Supervision and Training of Quality Assurance department employees Achievements • Set up quality product review program • Reduced customer quality issues • Revised product specifications • Improved customer relations and satisfaction Birchwood Foods, Frankfort, IN 2003-2006 Meat Processing Quality Assurance Manager • Supervised and Trained Quality Assurance Techs and managed department • Handled all labeling functions, submittals, creation, etc. • Responsible for writing of product specifications and product formulas. • Managed all HACCP Plans and Programs

- 3. • HACCP team Chairman Achievements • Rewrote HACCP, S.S.O.P. and G.M.P. Programs • Reduced NR’s by 10% • Plant passed Silliker Audit- 2004 Achieved Good Rating-2005 • Plant approved by Wal-Mart, Safeway, Wegman’s & Advance Foods for production of their products • Created monitoring programs, audits, forms and systems for new Entrée Product Line • Revised Environmental Swabbing Program and created LM Testing Program. Michigan Turkey Producers, Wyoming, MI 1999 – 2003 Poultry Processing HACCP Administrator: 2002-03 • Maintained and updated HACCP Program. • Implemented all revisions. • Provided HACCP Training to all employees Quality Assurance Manager: 1999 – 2002 • Responsible for all Quality Assurance functions for the Michigan Turkey Producers Company. • Supervise 9 employees including 1 Q.A. Supervisor, 2 Chemists, and 6 Q.A. Techs. • Responsible for HACCP, Sanitation Standard Operating Procedures and HIMP. • Primary contact for U.S.D.A. • Responsible for product specification. • Product development responsibilities. • Responsible for customer inquiries, correspondence, company relations, etc. • Chair of the HACCP Team • Member of the National Turkey Federation Technical and Reg. Committee. Achievements: • 11th employee of the Michigan Turkey Producers Company and heavily involved in the startup of the company • Developed HACCP and Sanitation Standard Operating procedures • Created all Q.A. programs, systems, procedures, plans, forms and check sheets. • Created GMP’s for plant. Wrote and designed Hygiene Manual for Plant. • Hired Quality Assurance Staff and developed department for company. • Developed food safety systems for plant. • Plant ranked #1 by U.S.D.A. for lowest incidence of salmonella found in testing. • Plant given Silliker Company’s Gold Certificate two consecutive years (their highest ranking) following their plant audits of our facility. • Plant passed audit by Russian Federation for shipment of product to Russia. Thorn Apple Valley 1994-1998 Meat Processing Quality Assurance Manager, Grand Rapids, MI • Supervised Quality Assurance Staff • Responsible for Label Approvals • Responsible for the Laboratory and Pre-Operational Inspection. • Directly involved with new product development and product formulations. • Maintained Quality Assurance Plant Records. • Handled consumer inquiries • Responsible for product recalls. • Coordinated Plant Food Safety Training Programs

- 4. Achievements: • Created HACCP Program for plant. • Revised S.S.O.P. Program for plant. • Reduced U.S.D.A. deficiencies by over 68% from previous year. • Created new Quality Assurance programs for AQL auditing. • Improved training program and reduced turnover of Quality Assurance employees by over 60%. Wilson Foods Corporation, Logansport, IN 1978-1993 Meat Processing Senior Q.A. Inspector • Online inspection and AQL Inspection of raw and finished products. • Assisted in new product development. • Responsible for shelf life research program for company. • Performed laboratory testing of products. • Conducted micro and analytical sampling of incoming raw materials. Achievements: • Helped to develop many new products, one of which won entrée of the year by Prepared Foods Magazine, resulting in record sales for the company. • Instrumental in the development of least costing system used for meat blending. Resulting lower costs, maintaining quality and producing a consistent product. Education: Bachelor of Science in Education, Ball State University, 1974 Bachelor of Science in Business, Ball State University, 1978 Continuing Education: • Total Quality Management Training, Wilson Foods Corporation, 1992 • STOP Safety Training, Thorn Apple Valley, 1994 • HACCP Training, Thorn Apple Valley, 1997. • Personnel Training, Thorn Apple Valley, 1997. • U.S.D.A. HACCP Training Seminar, 1998. • HACCP Certification Course, American Meat Science Association, 1998 • HACCP Training, Michigan Turkey Producers, 2000. • Advanced HACCP and IDV Training, HACCP Consulting Group, 2000 • HACCP Lead Instructor Certification, International HACCP Alliance, 2000. • Applied Statistical Quality Control Training, Northwest Analytical, 2001. • Business Management Training, Grand Rapids Community College, 2001. • Seafood HACCP Certification, University of Connecticut, 2008. • SQF Training, Silliker, 2010. • SQF Lead Auditor Training, NSF, 2013 • BRC GAP Training 2015 References: Oscar Moore, Jr. BRC Auditor Amity Packing (630) 709-6602 oscarmoorejr@att.net Dr. Mohammed Azam Former Director of Technical Services and Regulatory Compliance at Culinary Farms Food Safety Consultant Drazam52@yahoo.com

- 5. (209) 603-9302 Cathy Miller Vice President of Business Development, Evergreen Signature Foods mathykiller@gmail.com (918) 697-9763 Cell Tom Henderson Assistant Corporate Quality Assurance Director, Kenosha Beef International LTD thenders@bwfoods.com (262) 859-2272 Ext. 351 Office (262) 620-7848 Cell Tom McKamey National Food Chemistry Director, EMSL Analytical, Inc. tmckamey@emsl.com (773)313-0099

- 6. (209) 603-9302 Cathy Miller Vice President of Business Development, Evergreen Signature Foods mathykiller@gmail.com (918) 697-9763 Cell Tom Henderson Assistant Corporate Quality Assurance Director, Kenosha Beef International LTD thenders@bwfoods.com (262) 859-2272 Ext. 351 Office (262) 620-7848 Cell Tom McKamey National Food Chemistry Director, EMSL Analytical, Inc. tmckamey@emsl.com (773)313-0099