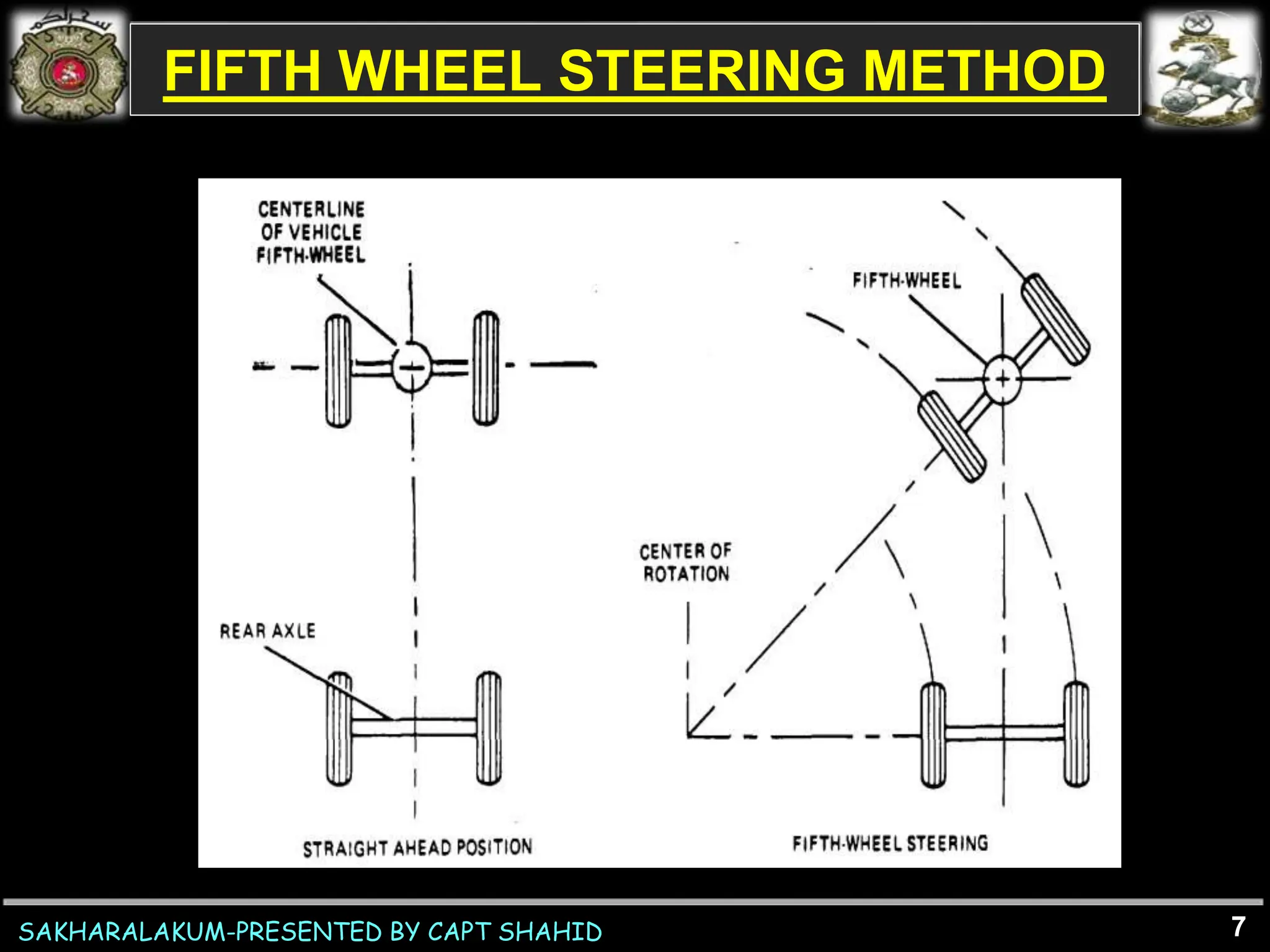

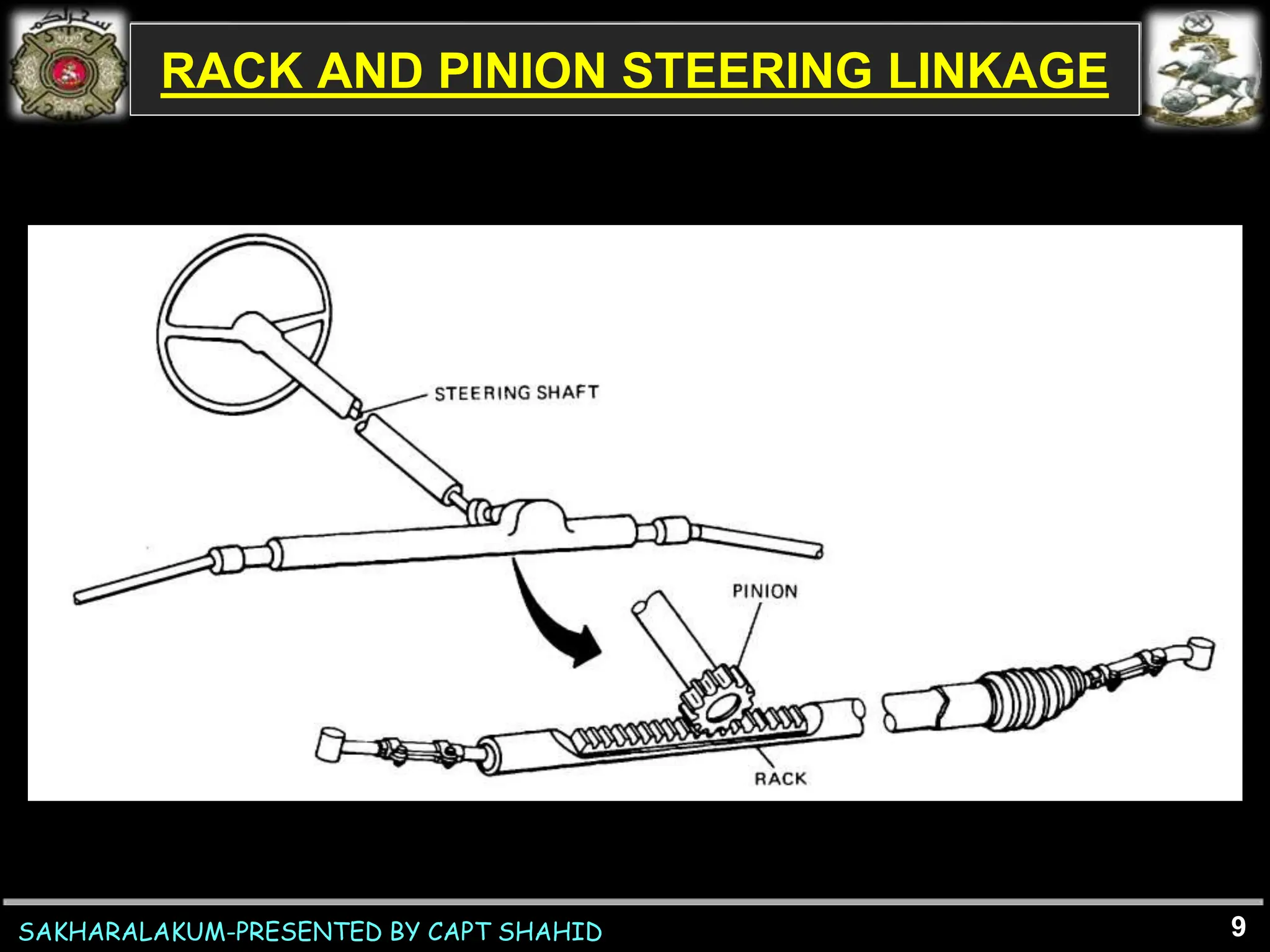

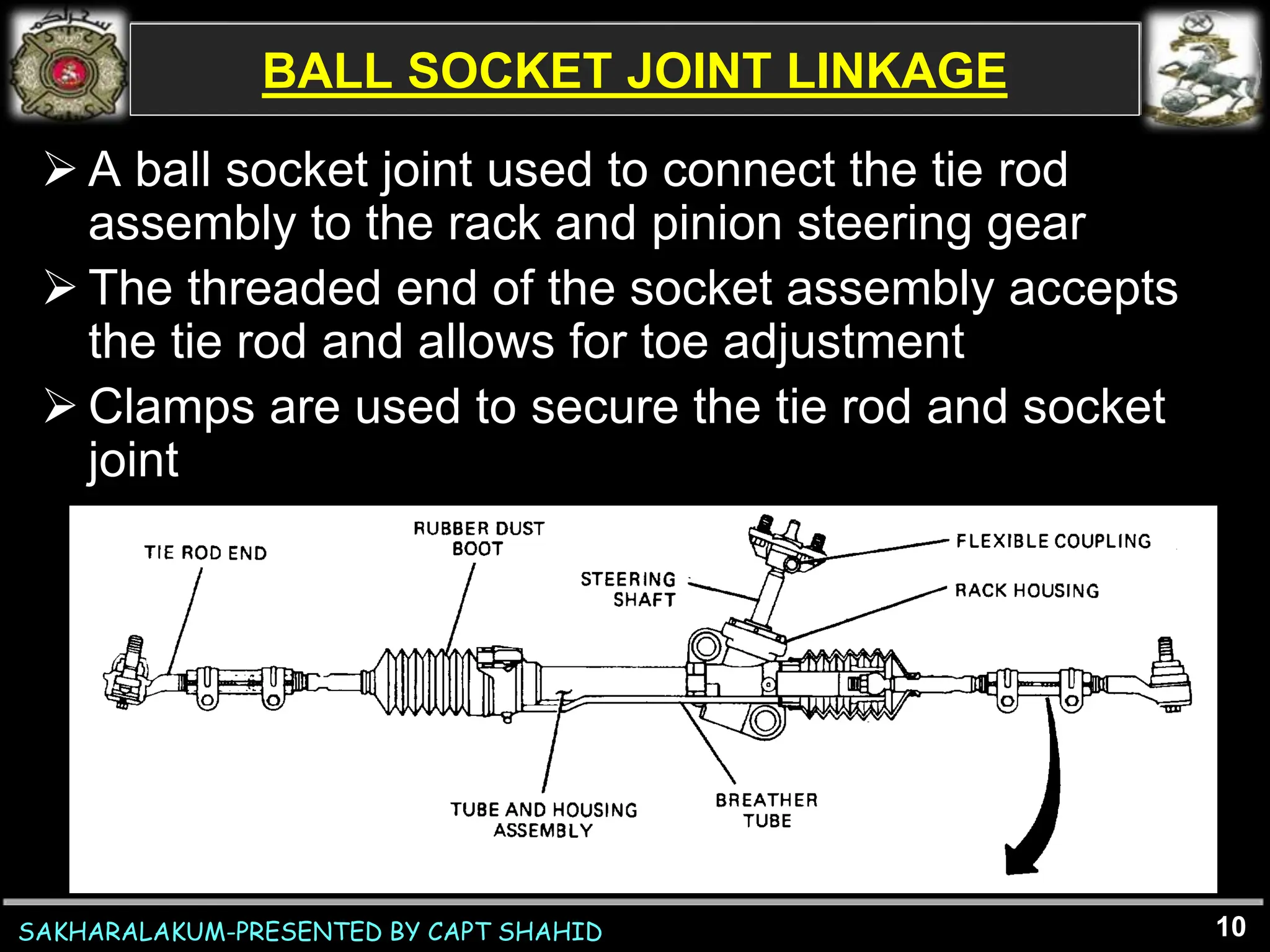

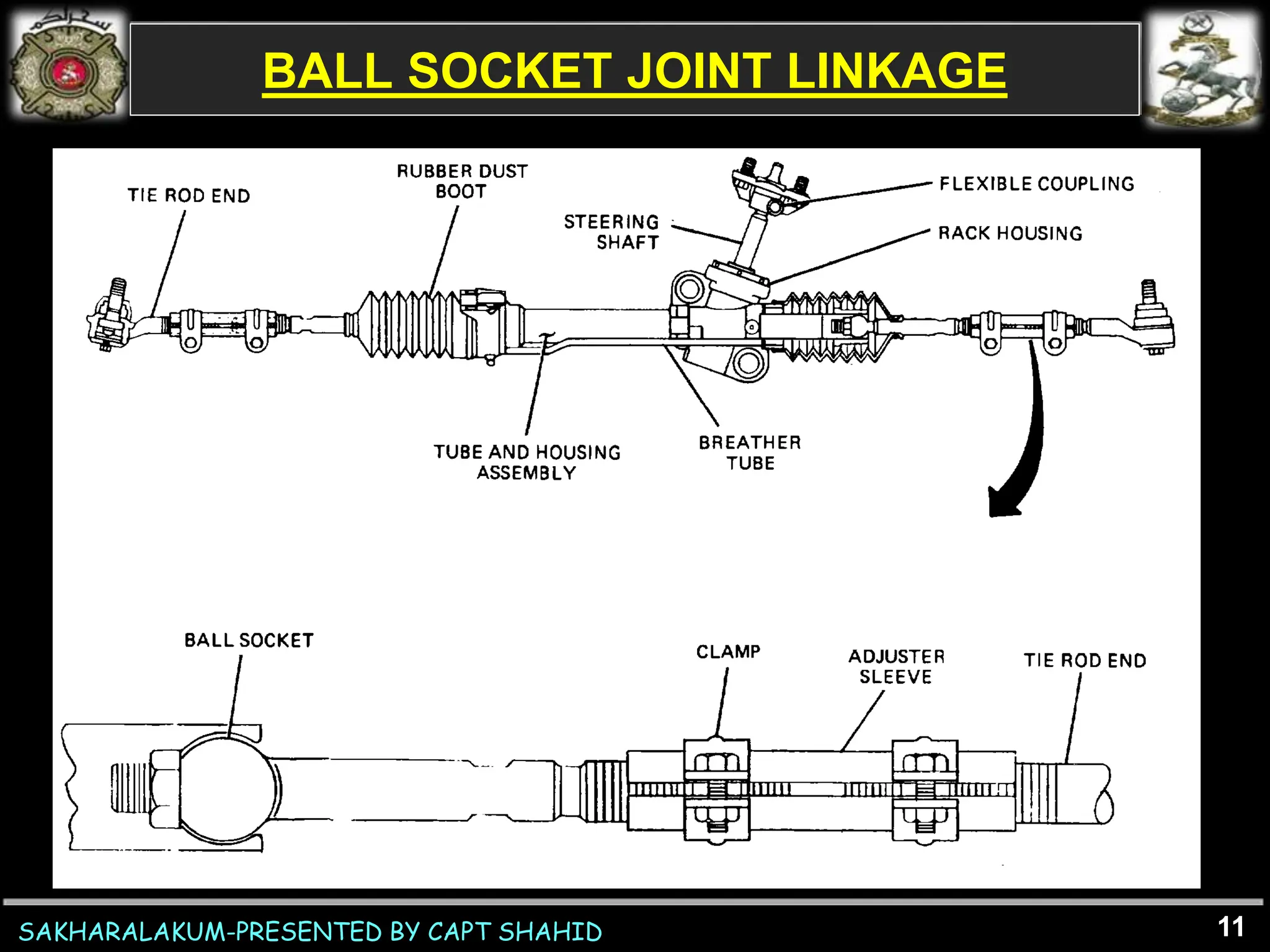

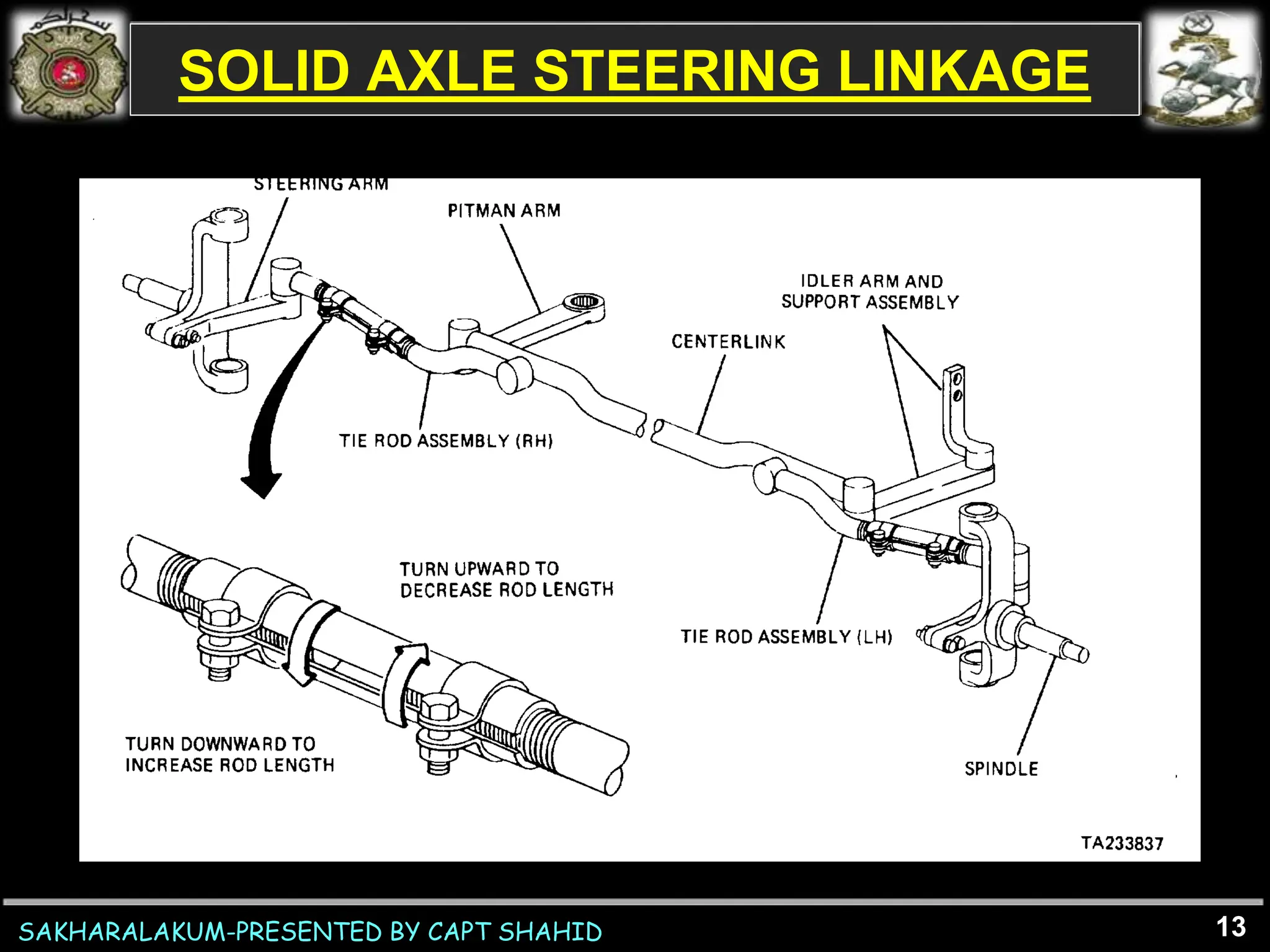

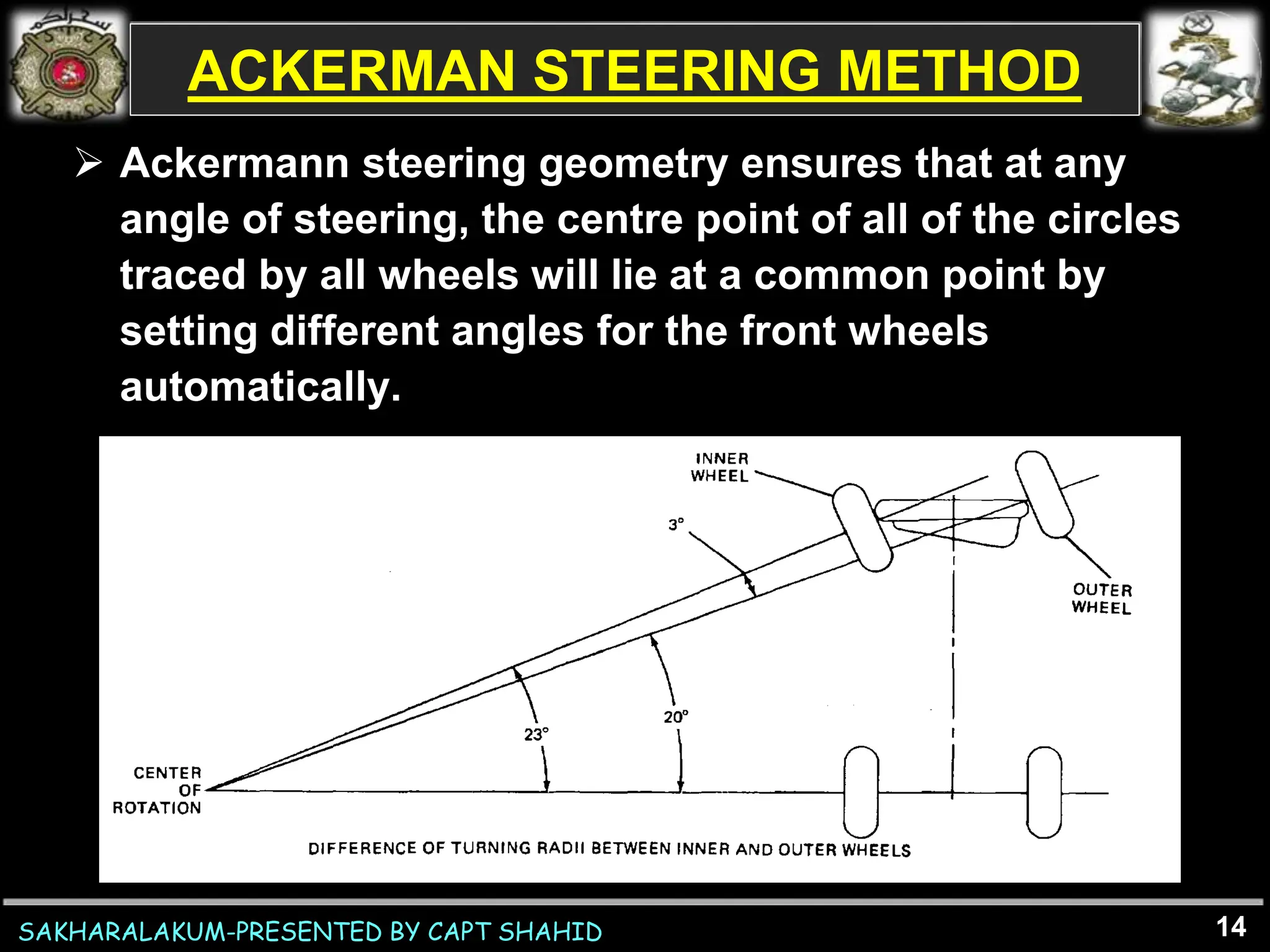

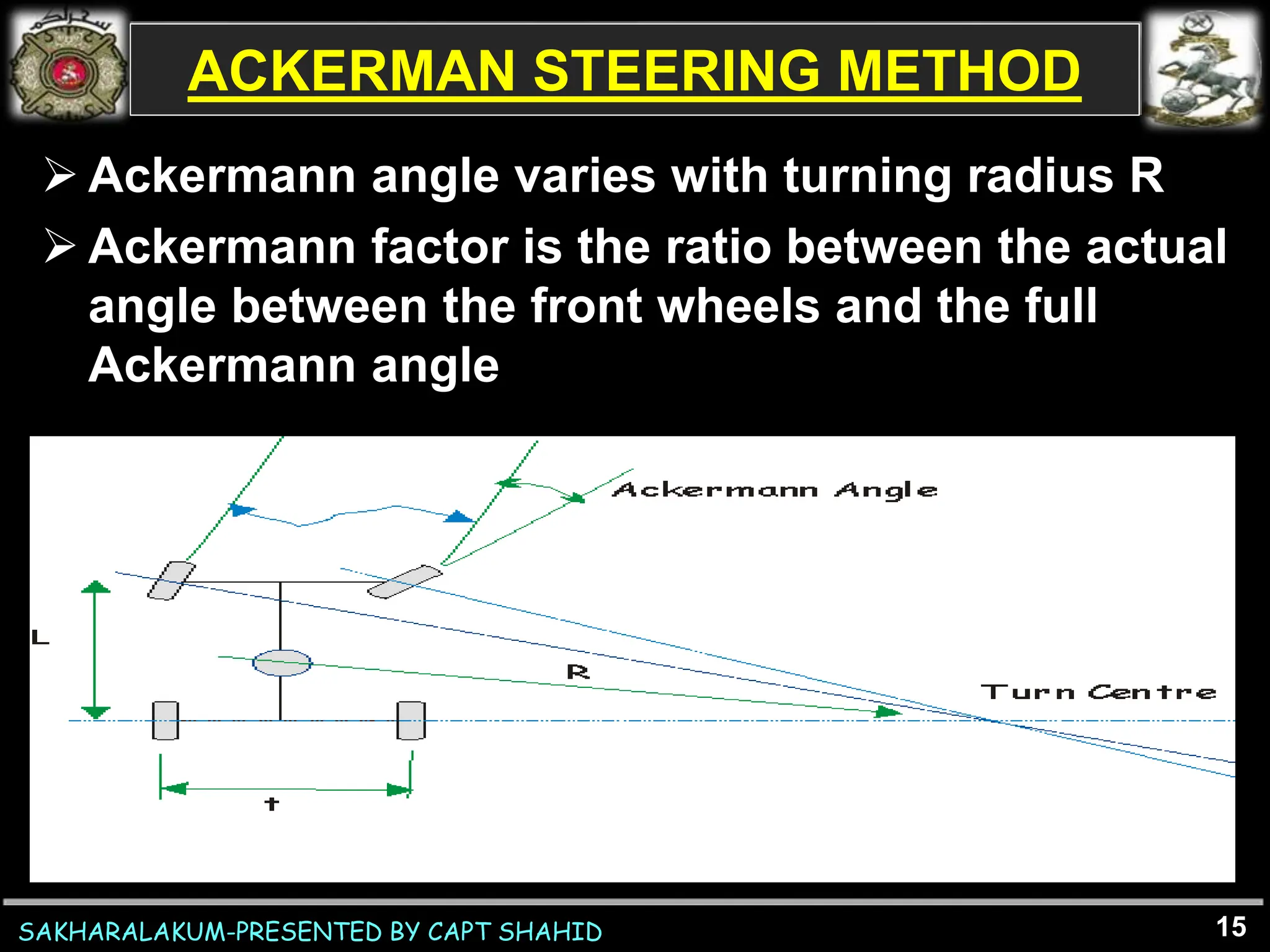

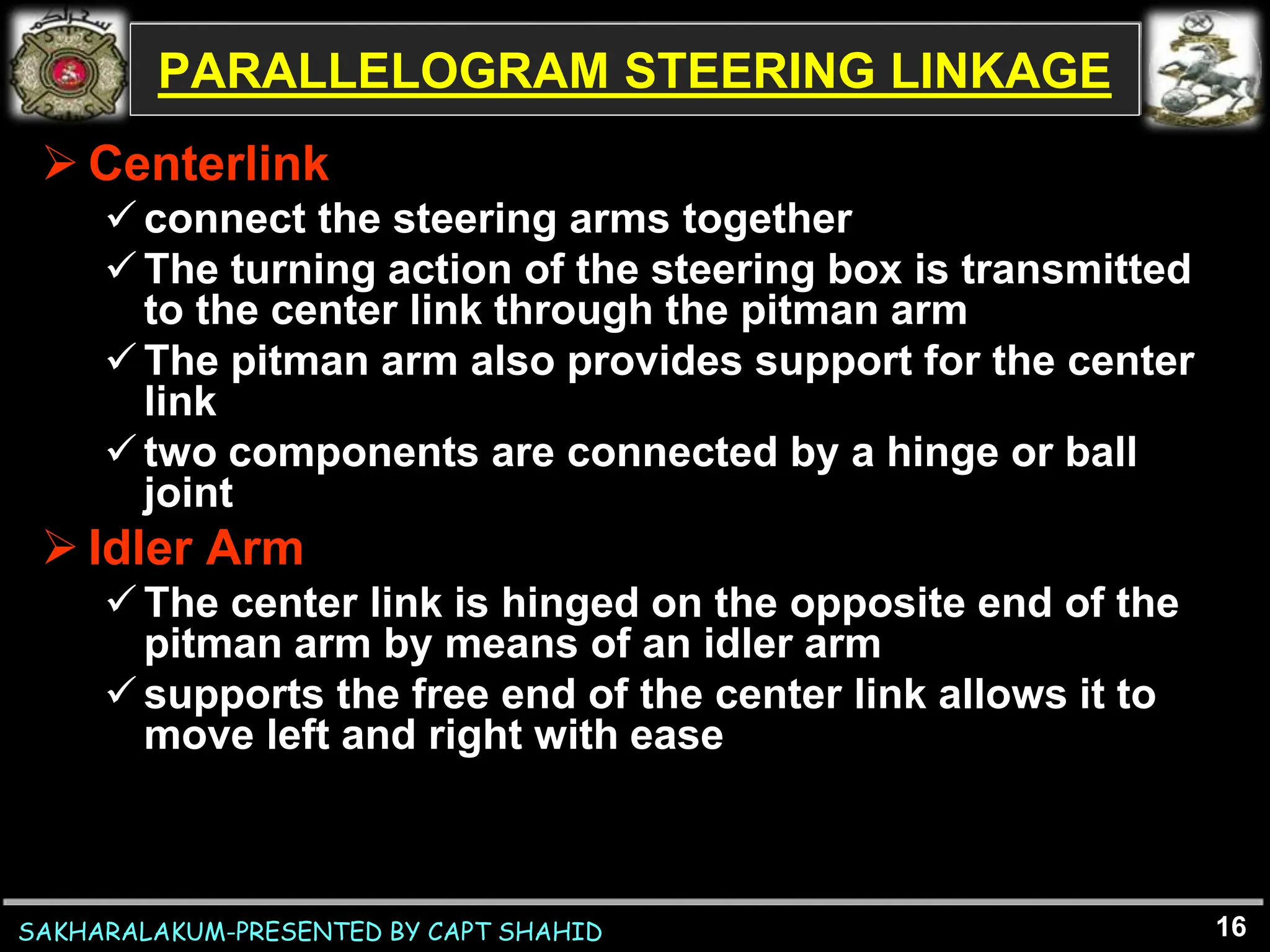

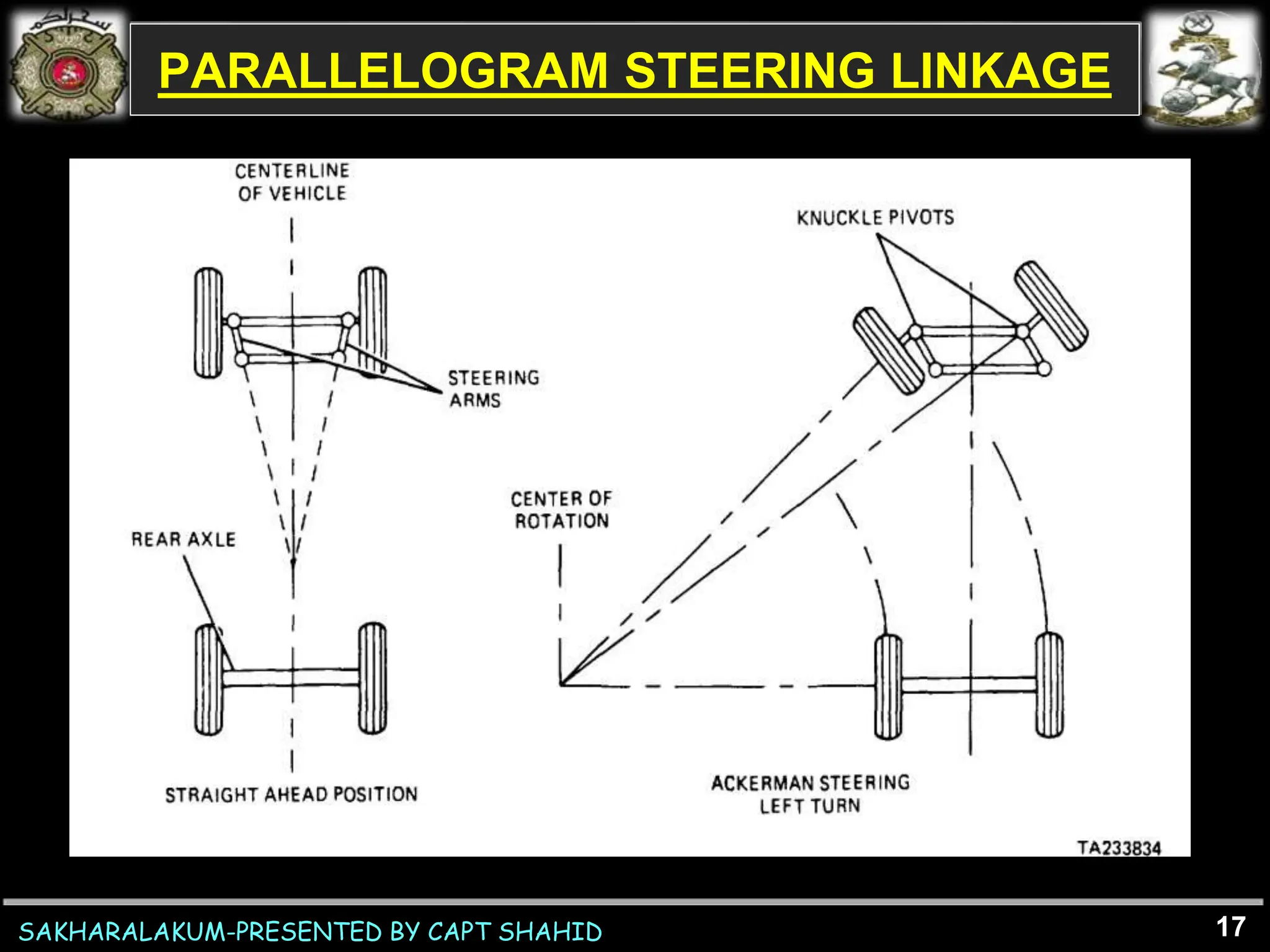

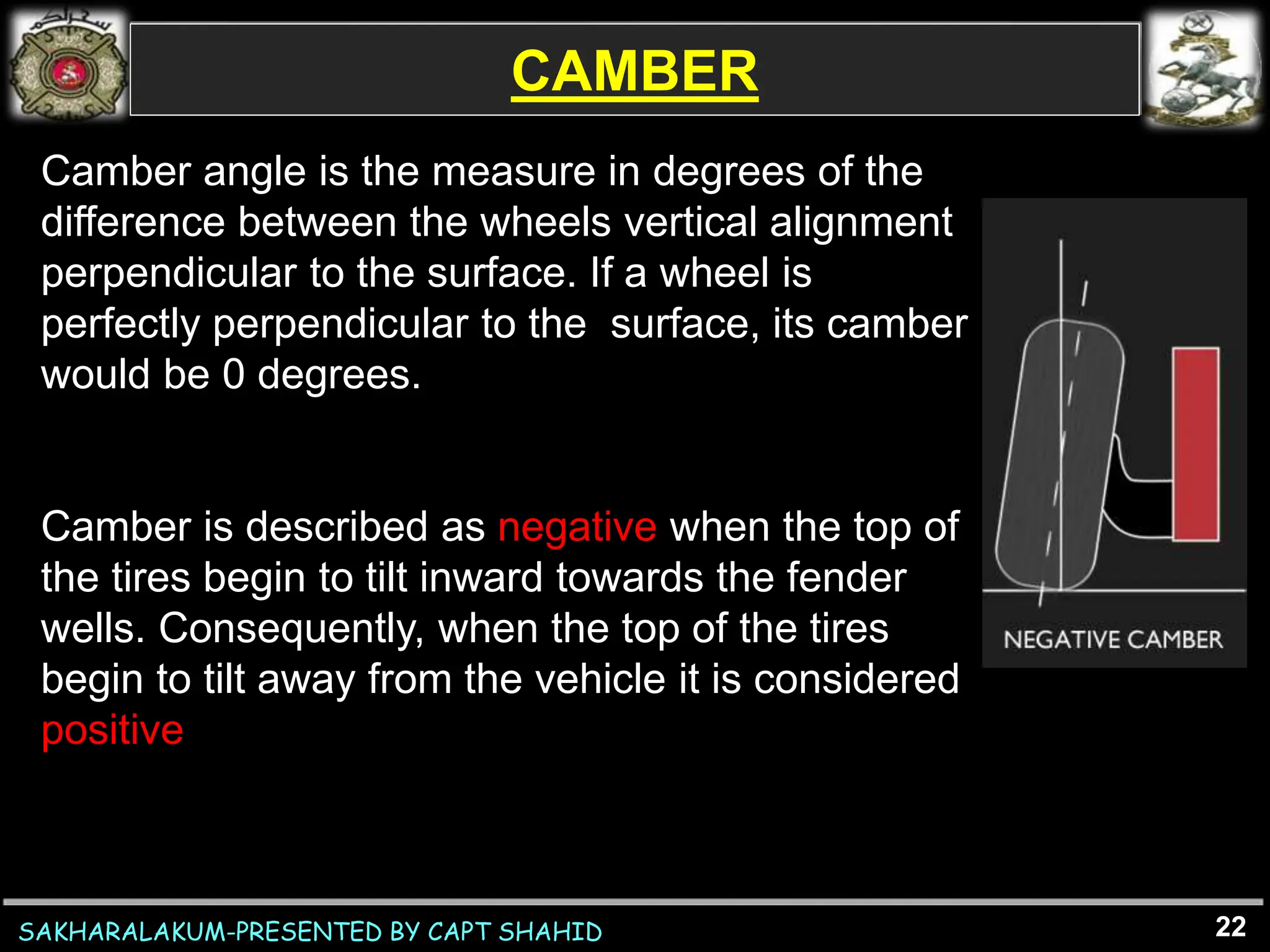

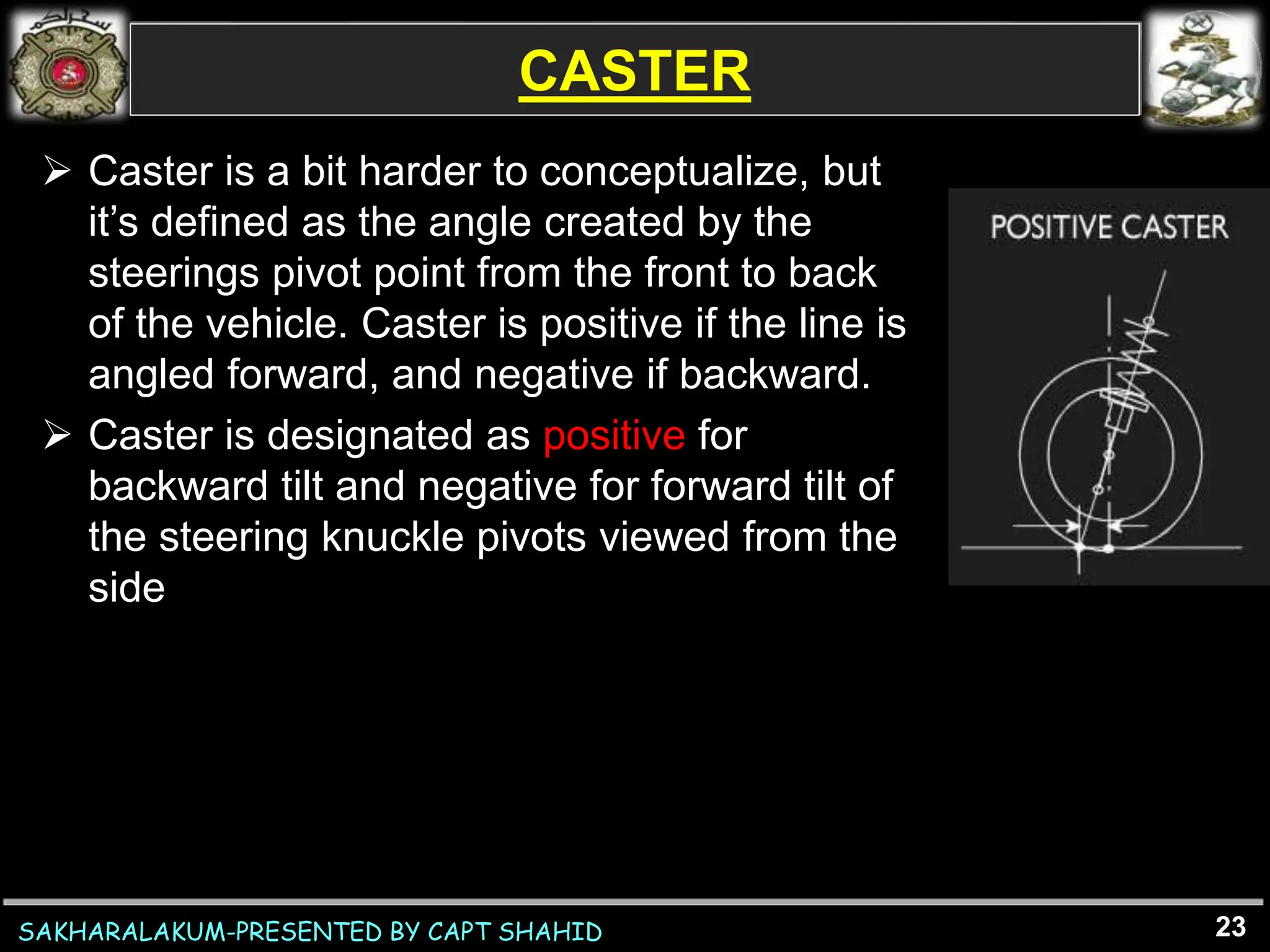

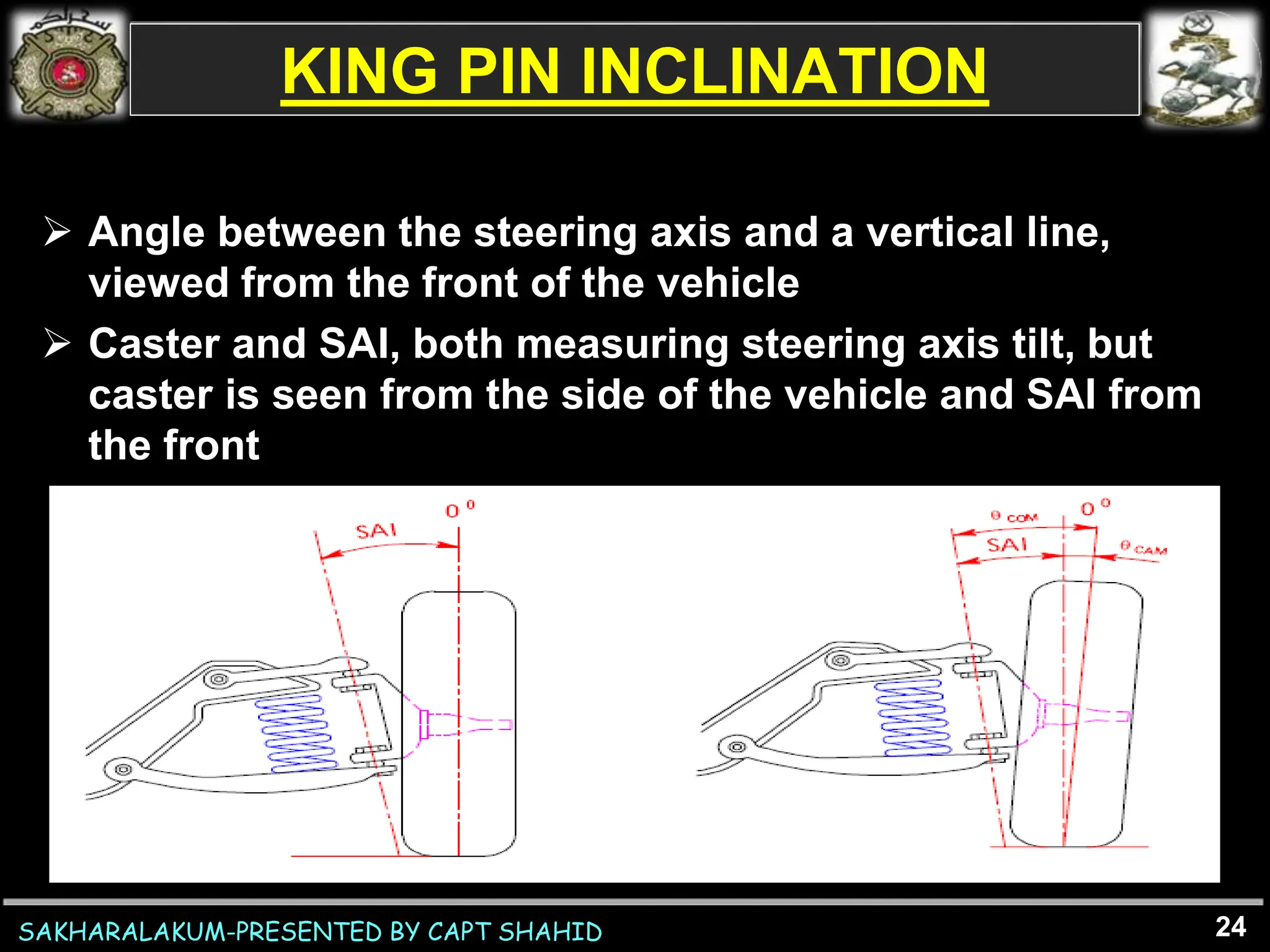

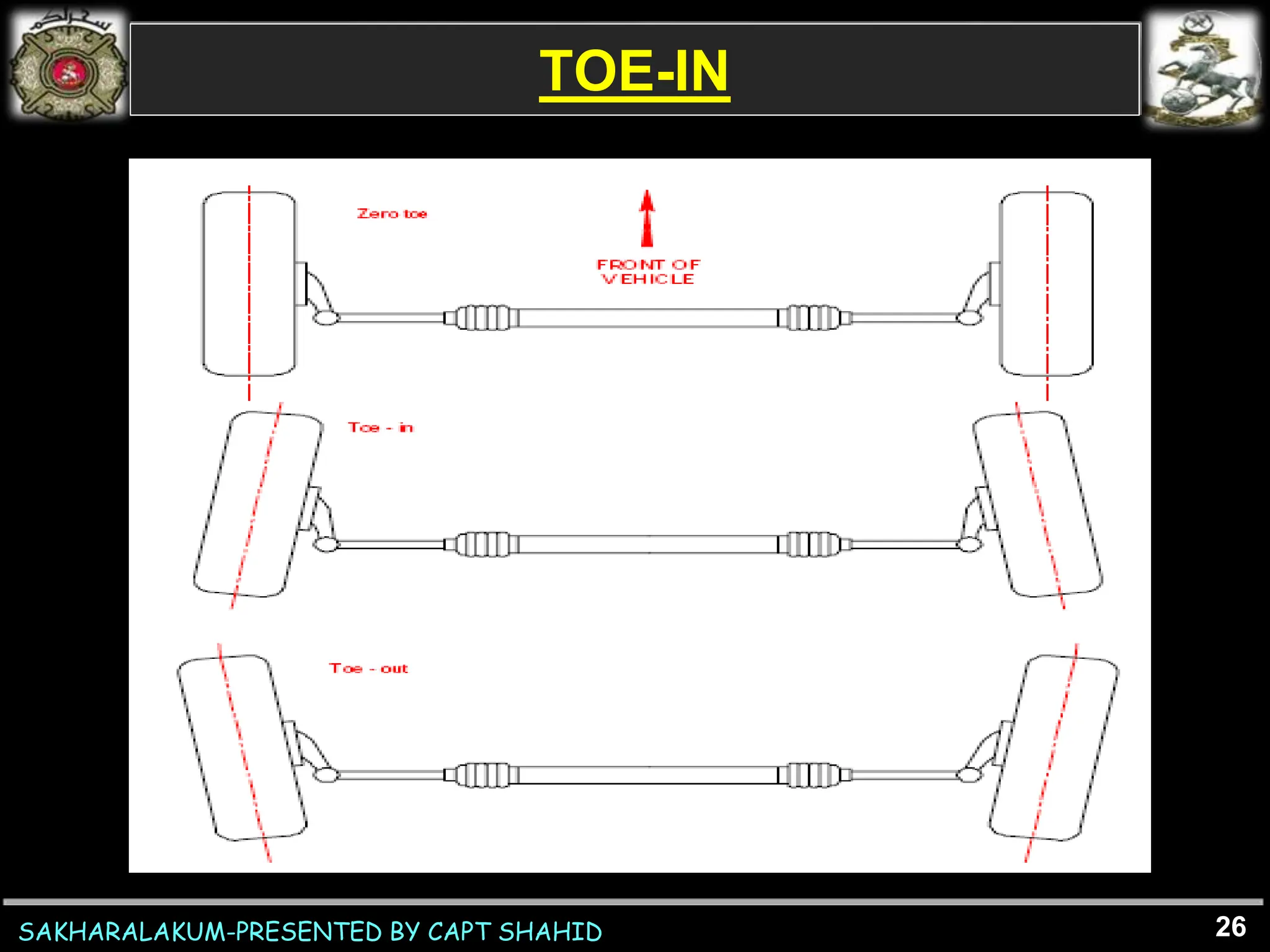

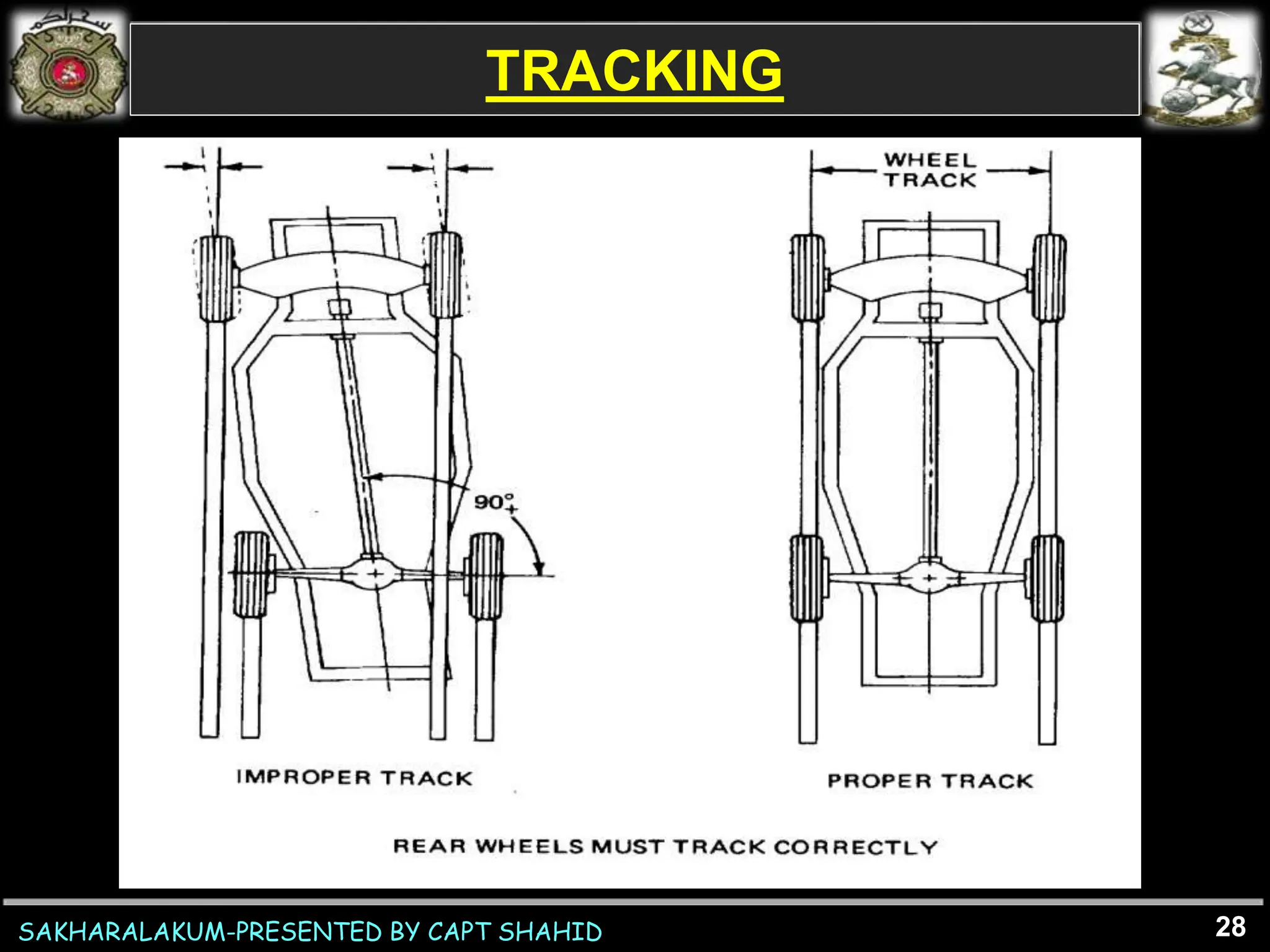

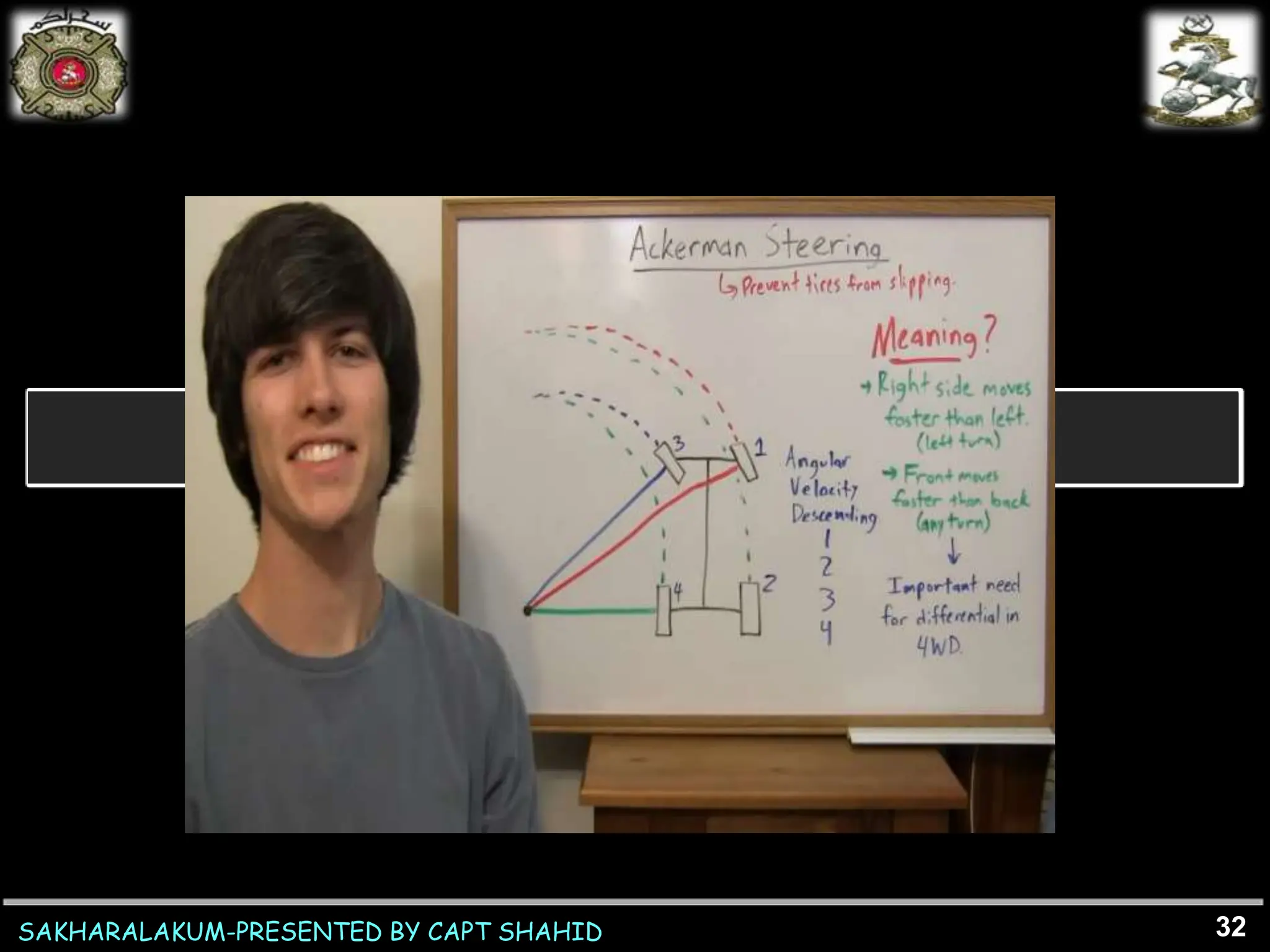

This document presents information about steering geometry and the components that affect it. It discusses the fifth wheel and Ackerman steering methods, parts of the steering system like the rack and pinion linkage, and parameters that impact steering such as camber, caster, king pin inclination, toe-in, and tracking. The aim is to educate students about steering geometry and how vehicle steering is achieved.