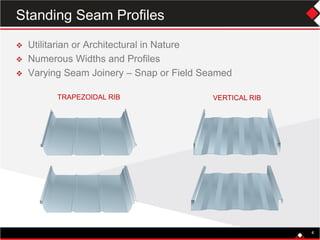

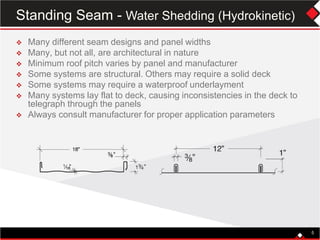

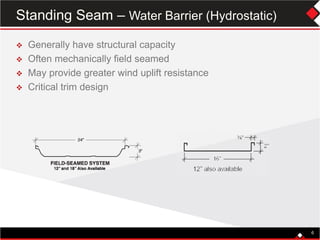

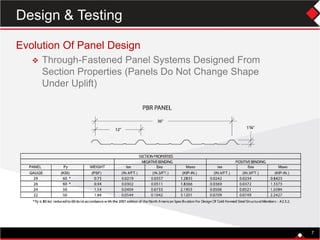

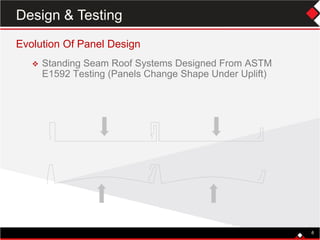

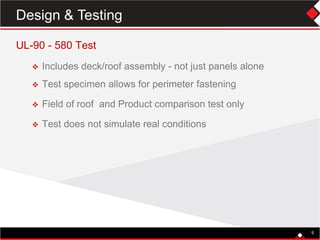

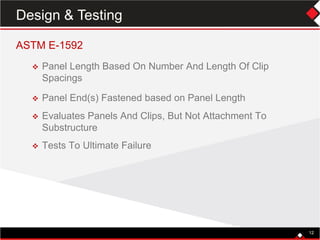

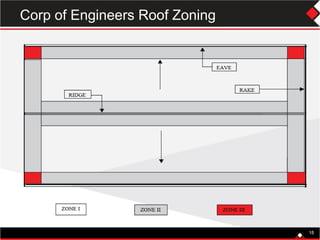

This document provides an overview of standing seam metal roofing systems. It discusses different profile types, application parameters, wind uplift testing standards, and important design details. It also covers available warranty options, emphasizing the importance of a "Day One" warranty that makes the manufacturer responsible for the roof from project completion. The presentation aims to help attendees understand metal roofing options, design challenges, and how to specify appropriate warranties.