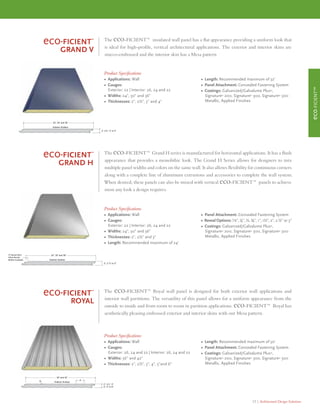

This document provides information on architectural design solutions from MBCI, including metal roof and wall systems. It summarizes various standing seam roof systems like LokSeam, SuperLok, BattenLok HS, curved BattenLok, and trapezoidal systems like Ultra-Dek and Double-Lok. It also discusses MBCI's line of insulated metal panels called eco-ficient panels, highlighting the insulated BattenLok and insulated R panel profiles. The document provides specifications and photos of completed projects utilizing MBCI systems.