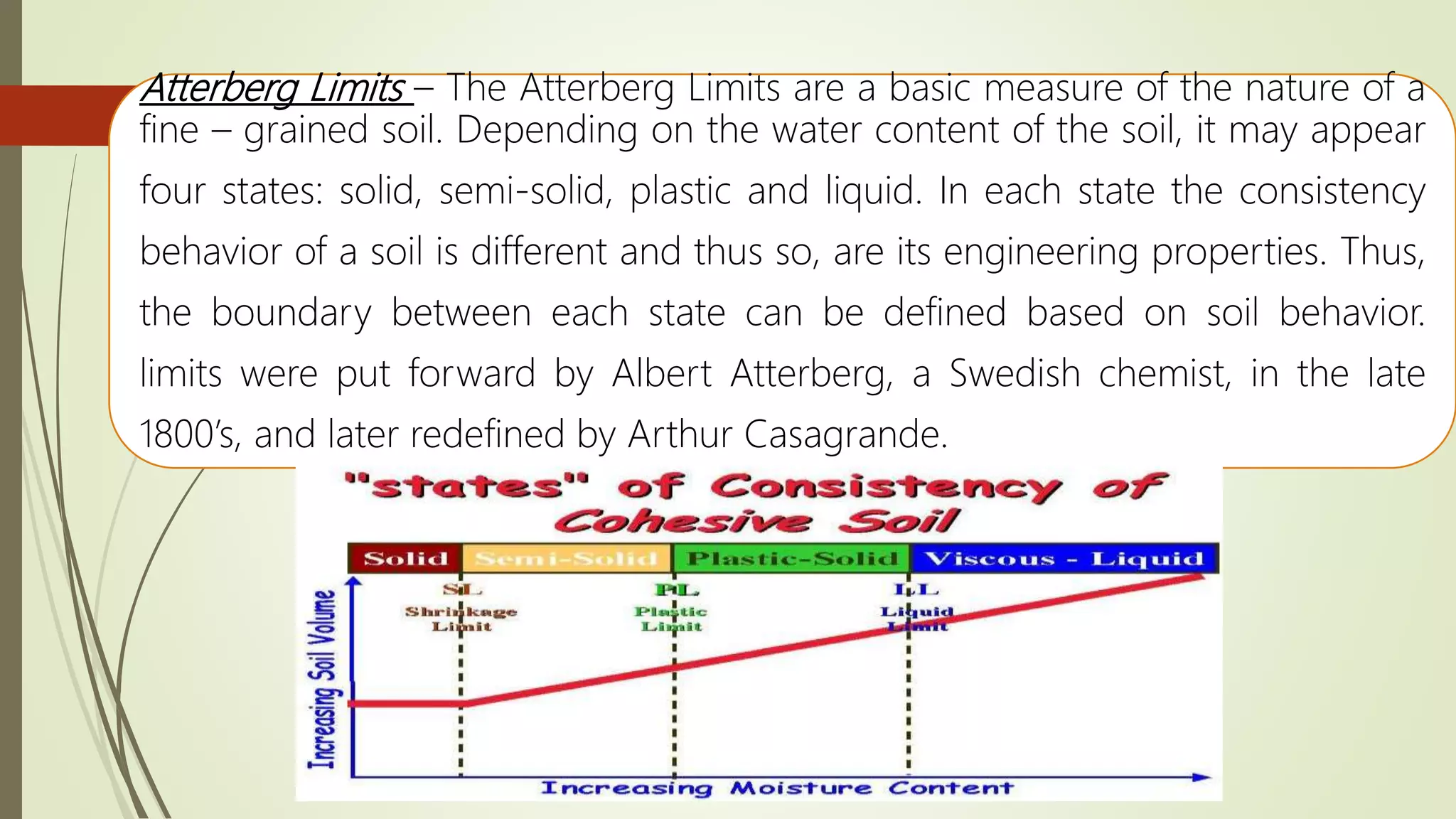

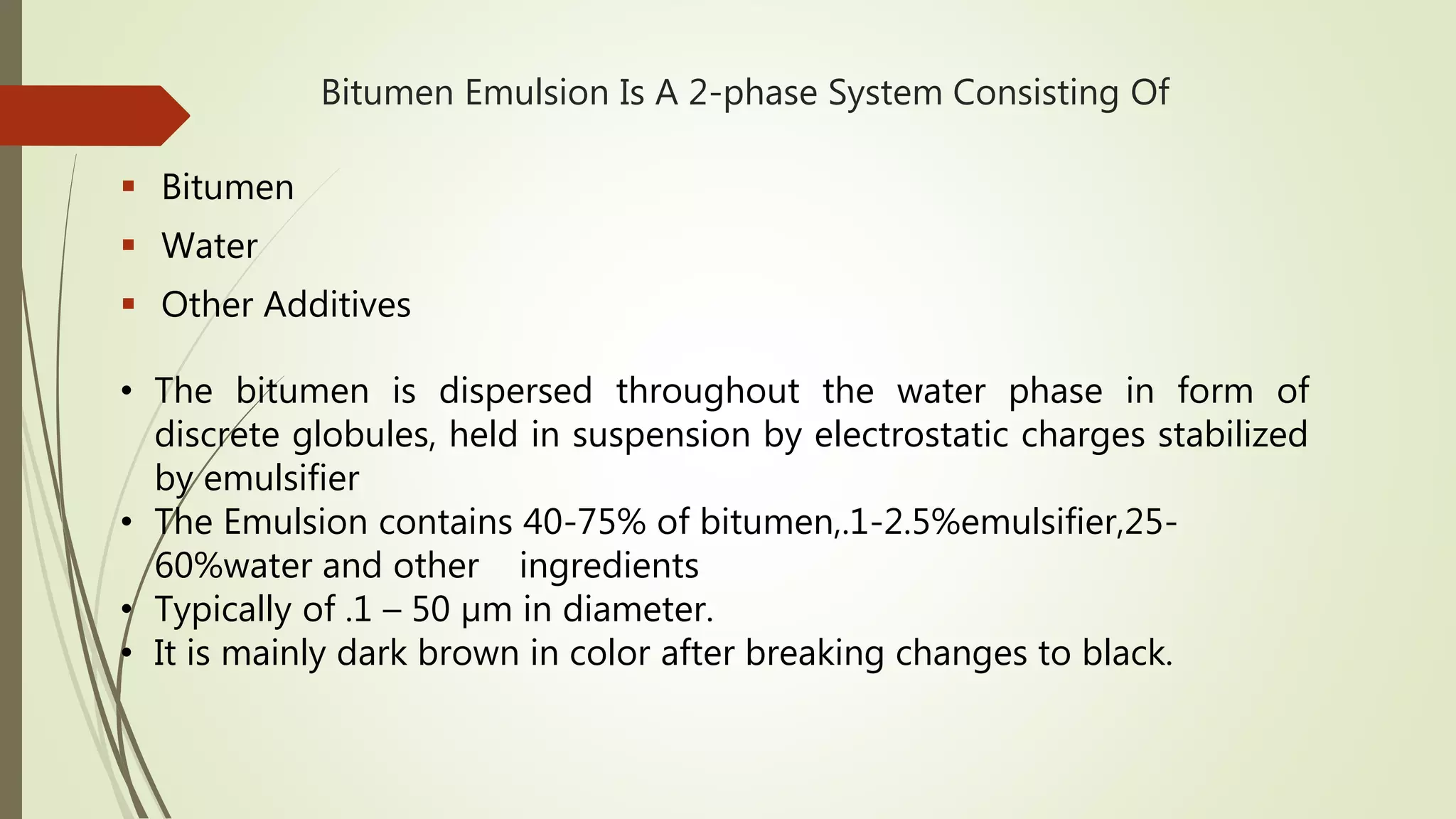

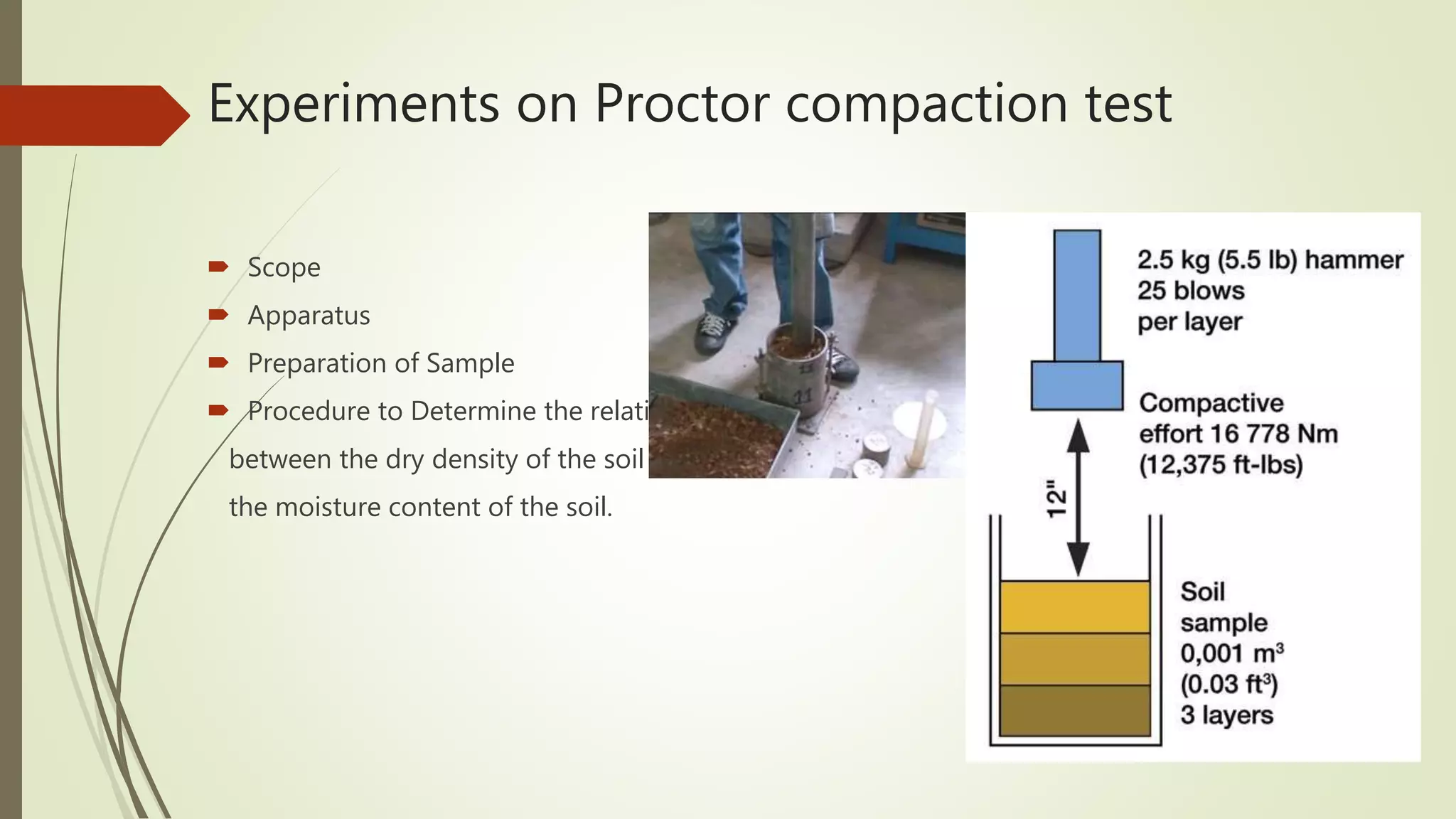

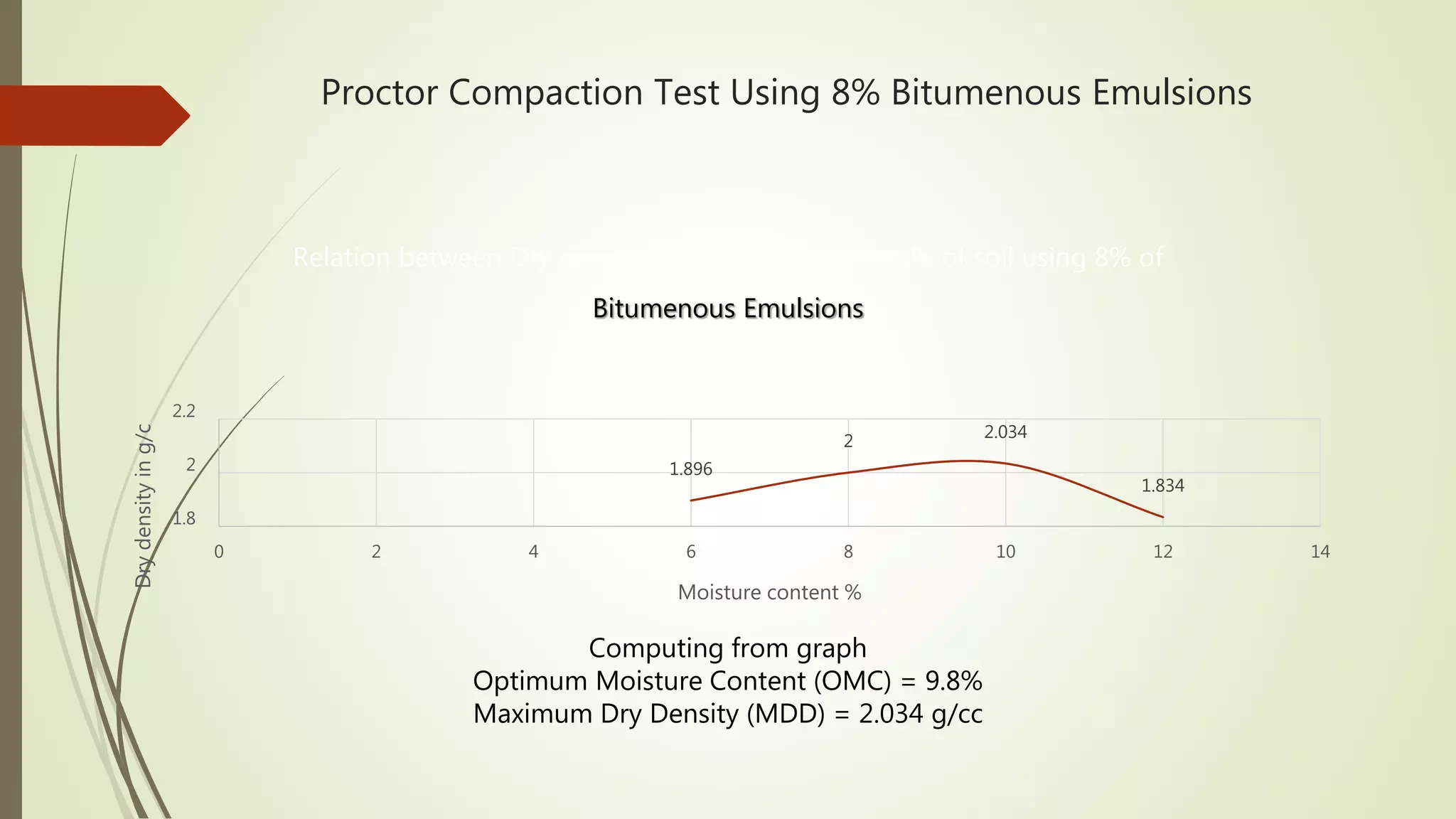

The document discusses soil stabilization using bituminous emulsions, highlighting the importance of soil properties and stabilization methods for construction. It elaborates on definitions, advantages of stabilization, types of emulsions, experimental results from proctor compaction and California bearing ratio tests, and concludes that bituminous emulsion is an effective ground improvement technique for weak soils. The document also categorizes soil types and their characteristics, emphasizing their relevance to construction and land use.