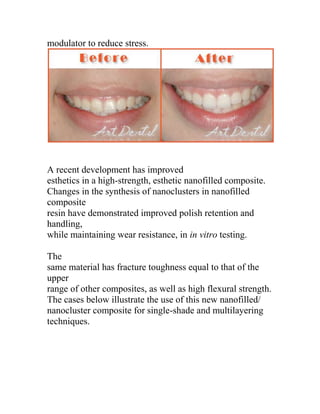

Dental composite resins have evolved significantly since their introduction in the 1960s. Early composites had large filler particles and exhibited high polymerization shrinkage, discoloration, and poor mechanical properties. Researchers developed smaller filler particles and introduced resin chemistry modifications to improve properties. Current composites include microfilled, microhybrid, and nanofilled types. While composites can provide esthetic posterior restorations, clinicians must take care with technique and moisture control for success. Composite properties continue advancing, but their performance still depends greatly on the skills and care of the applying dentist.