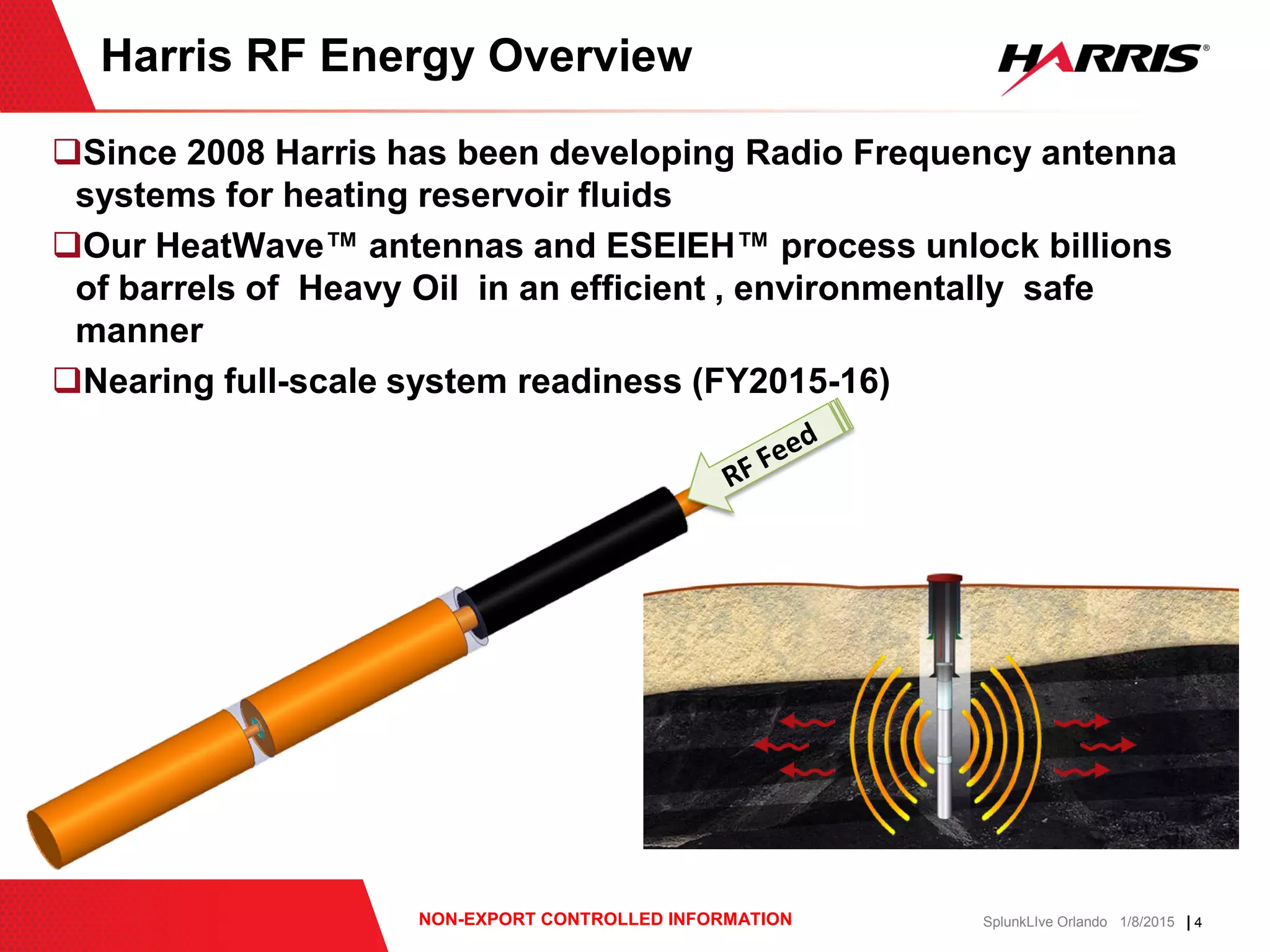

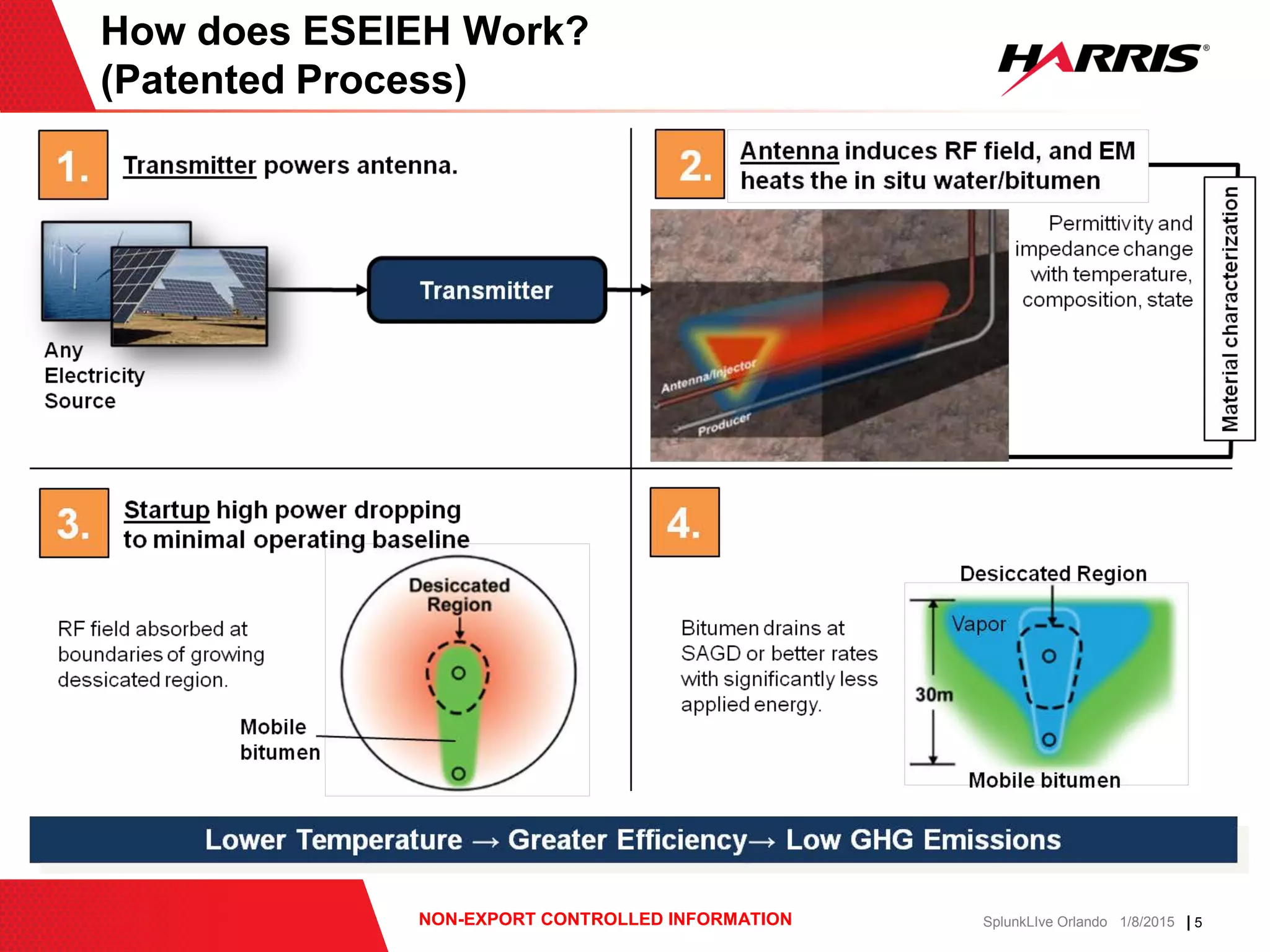

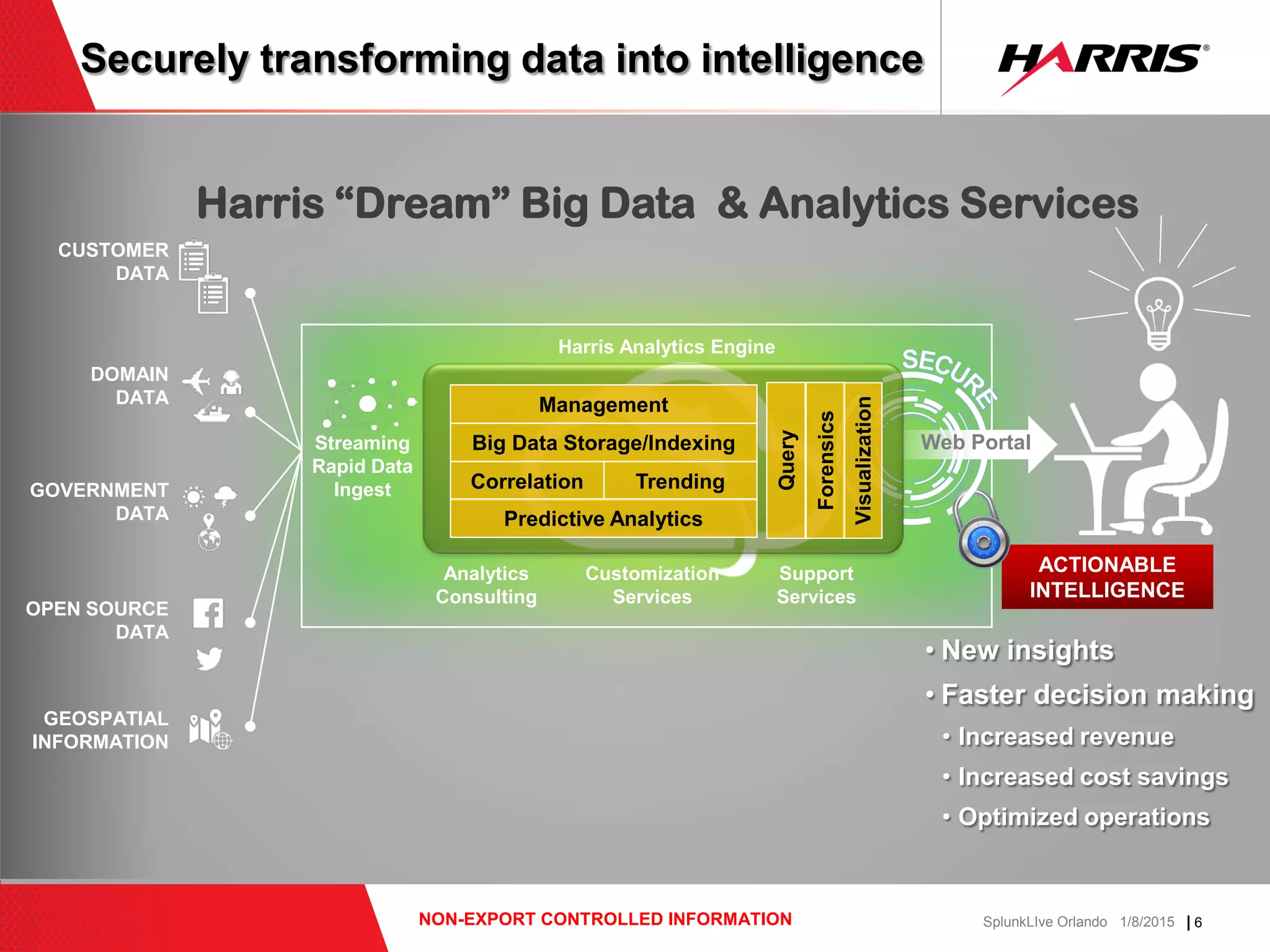

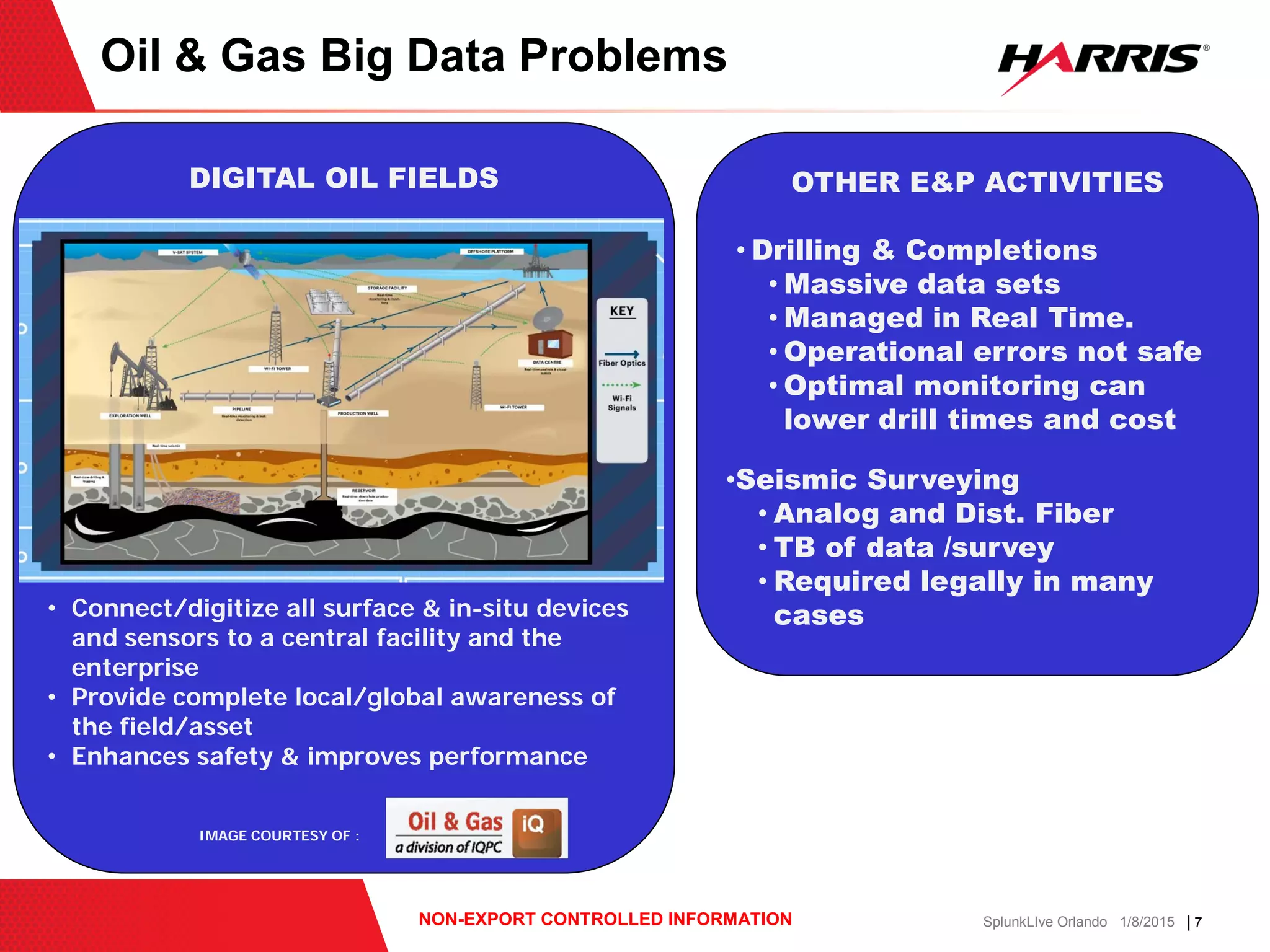

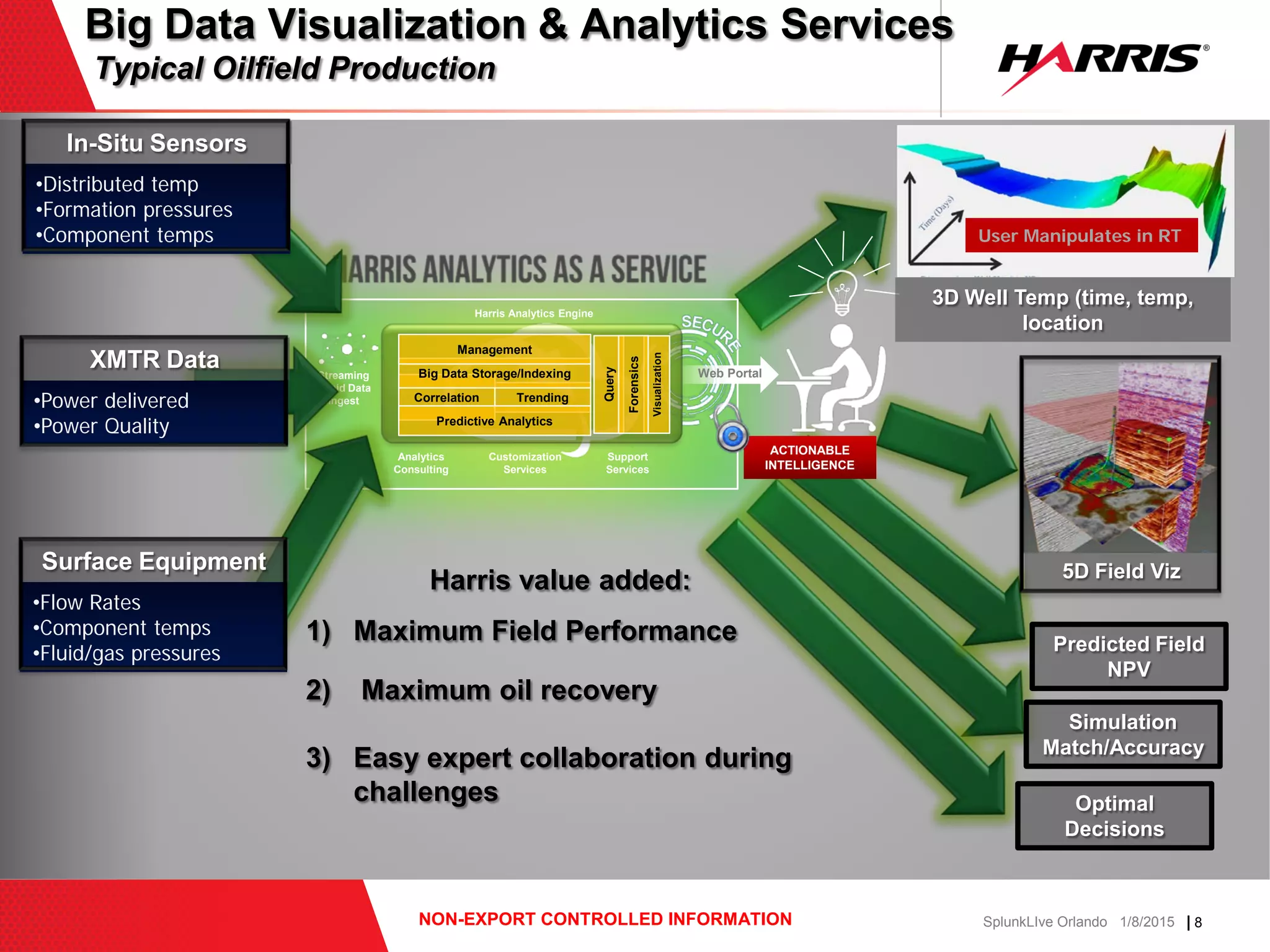

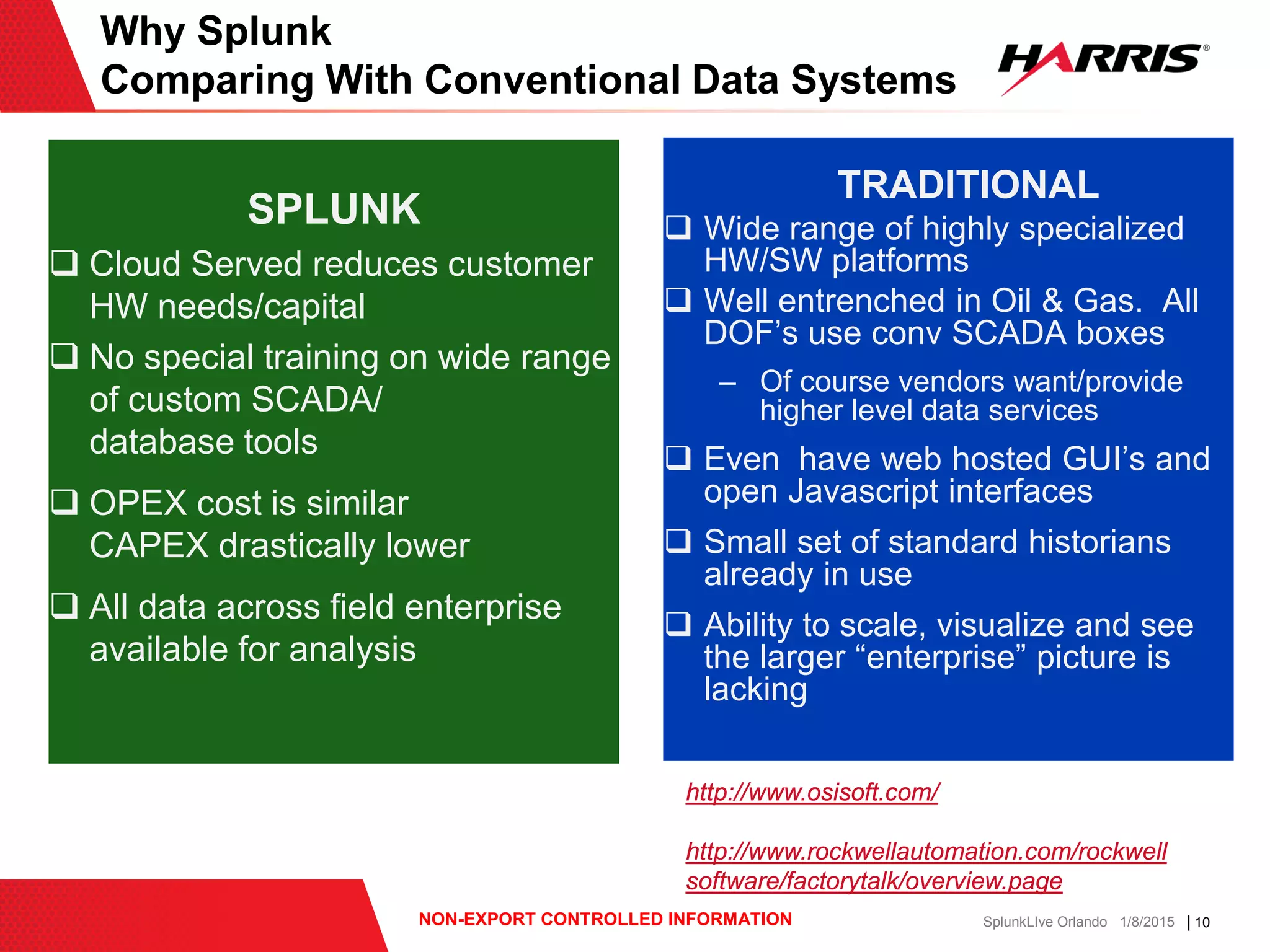

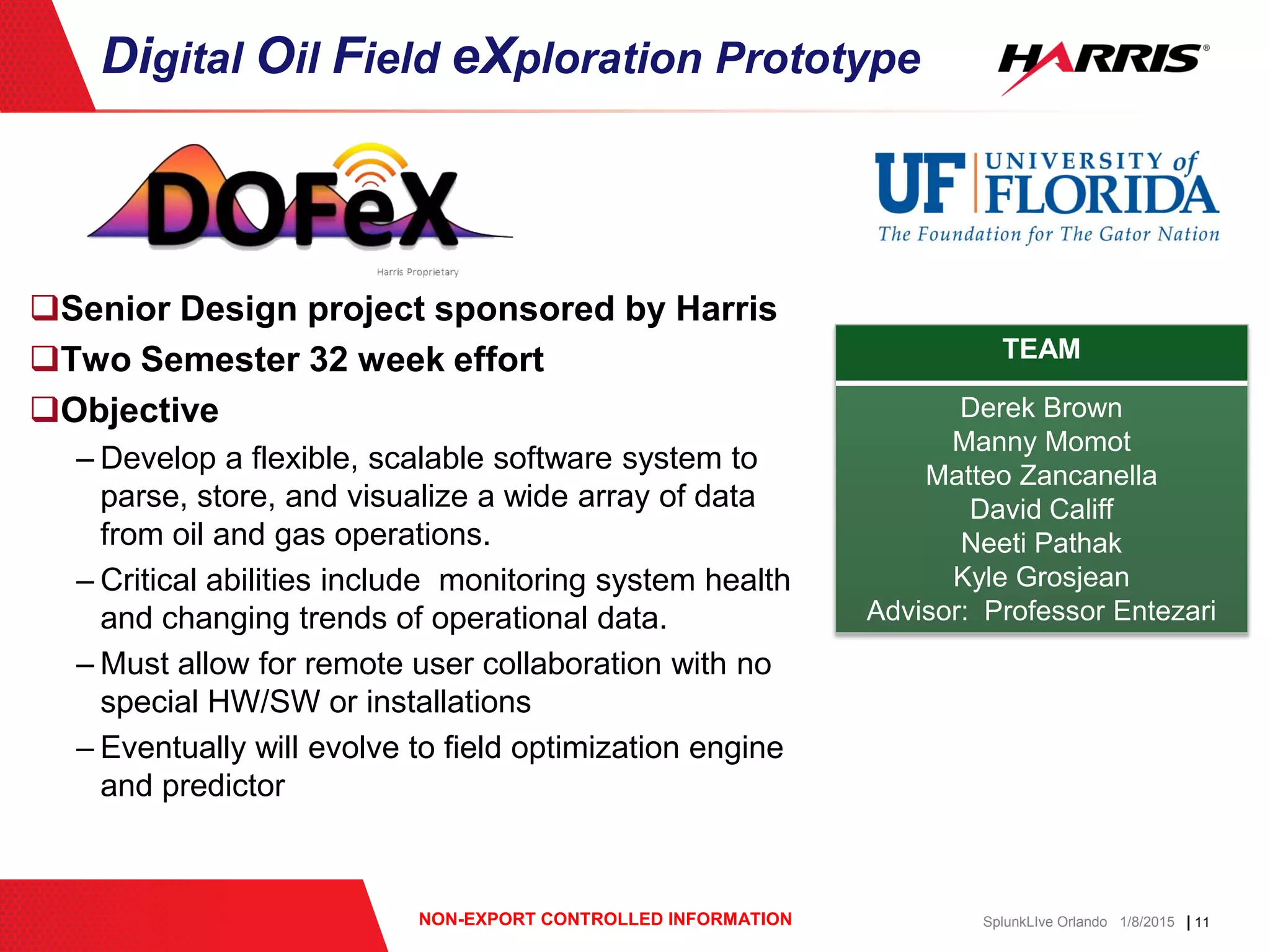

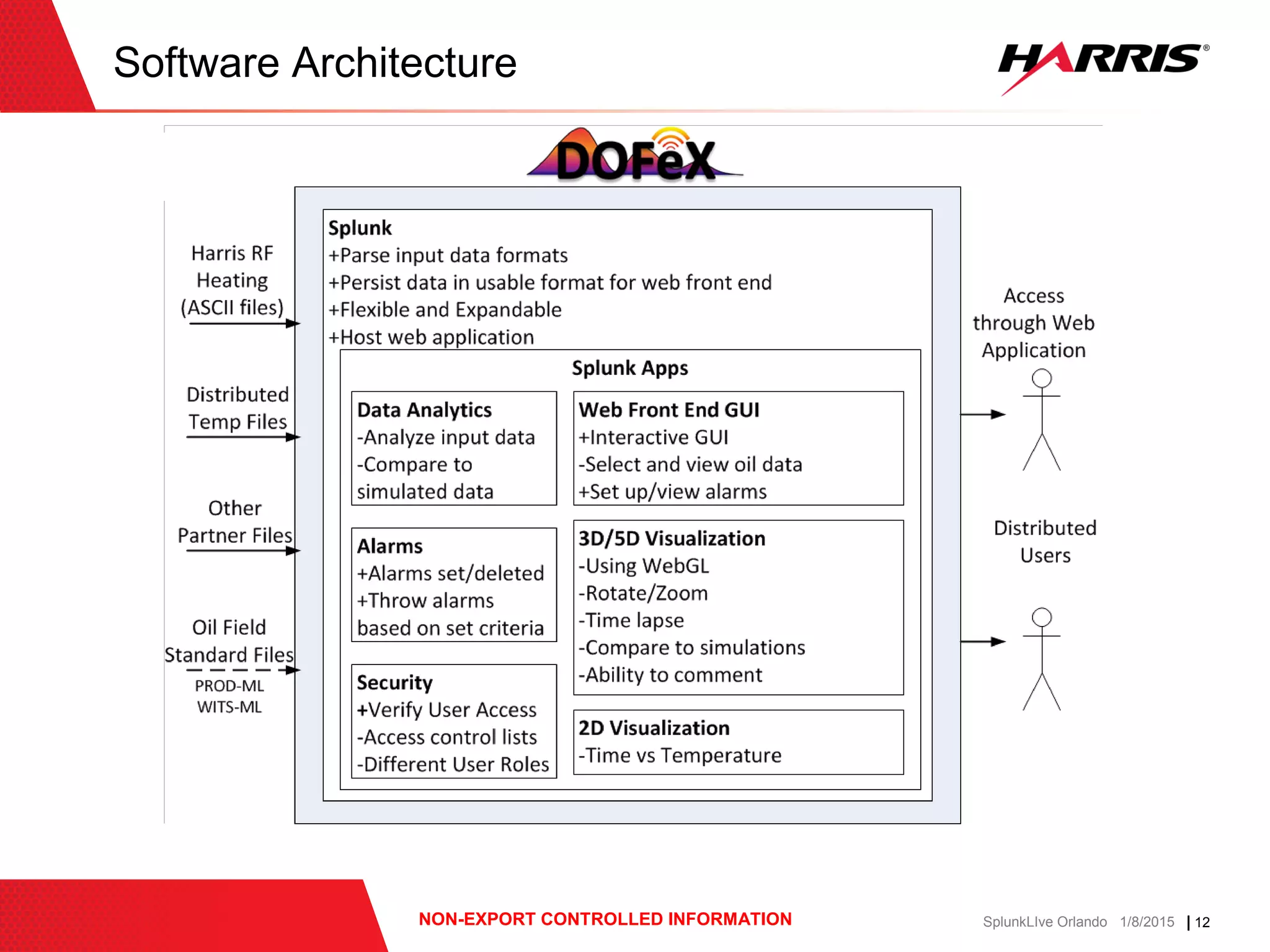

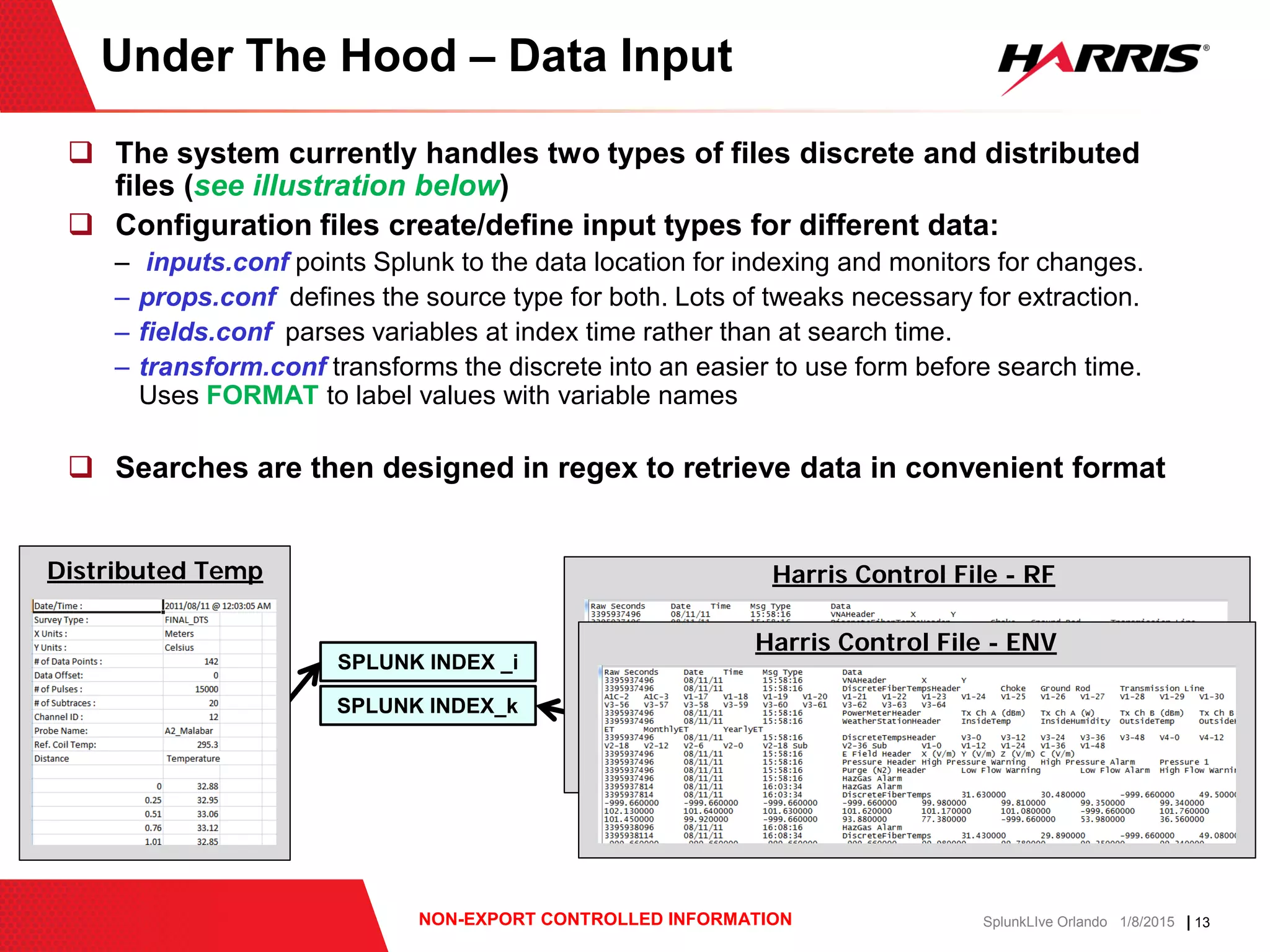

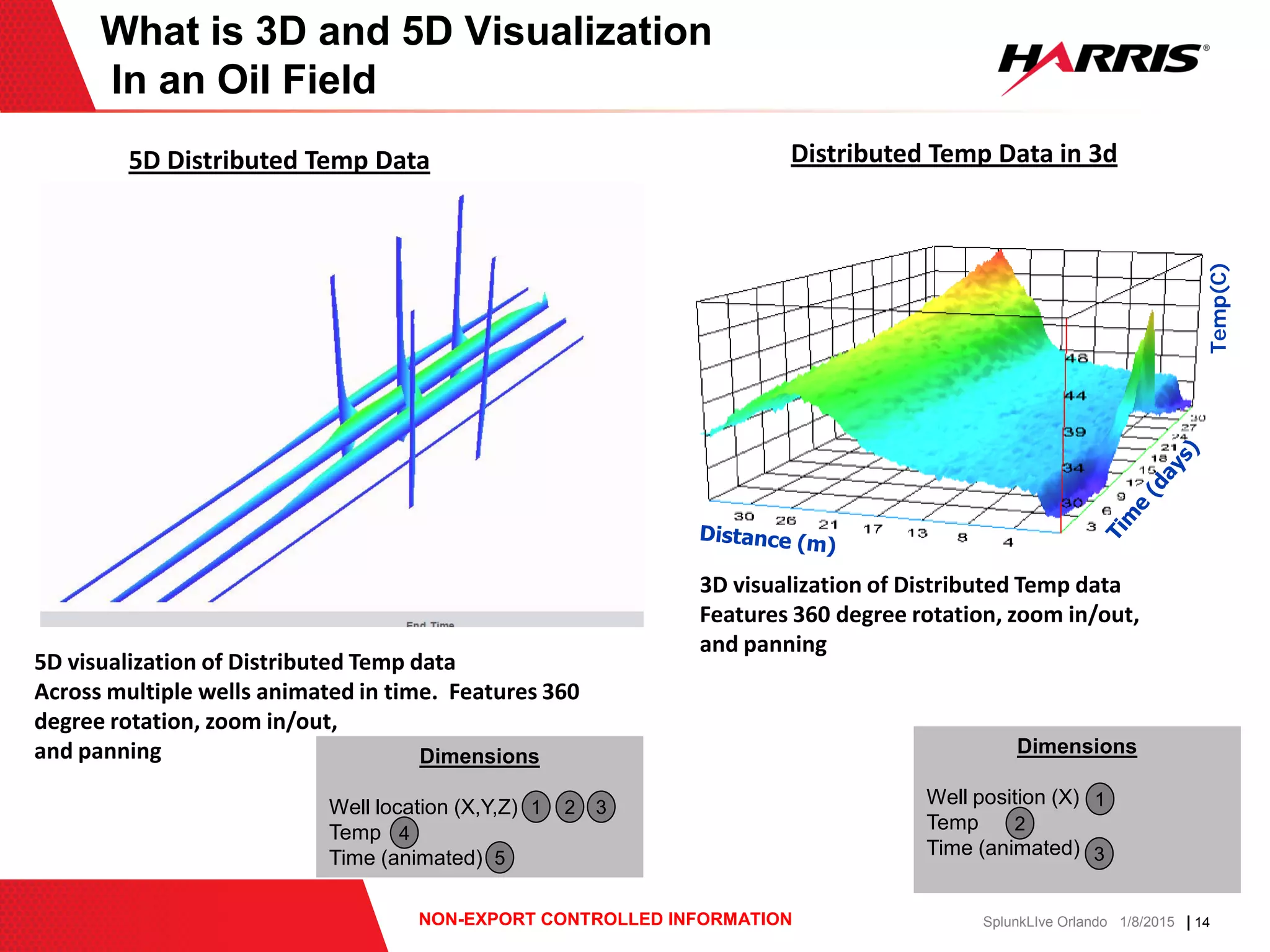

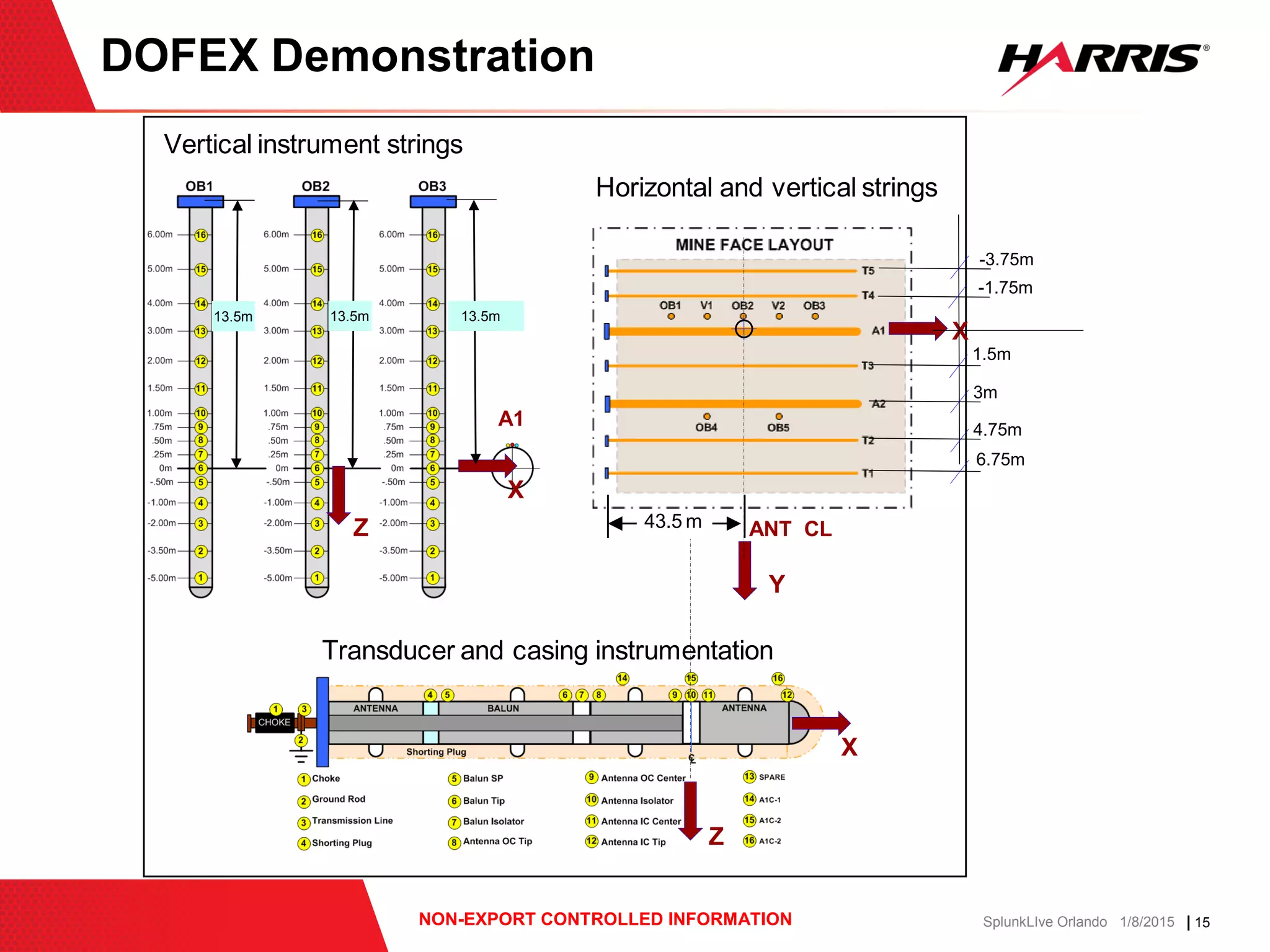

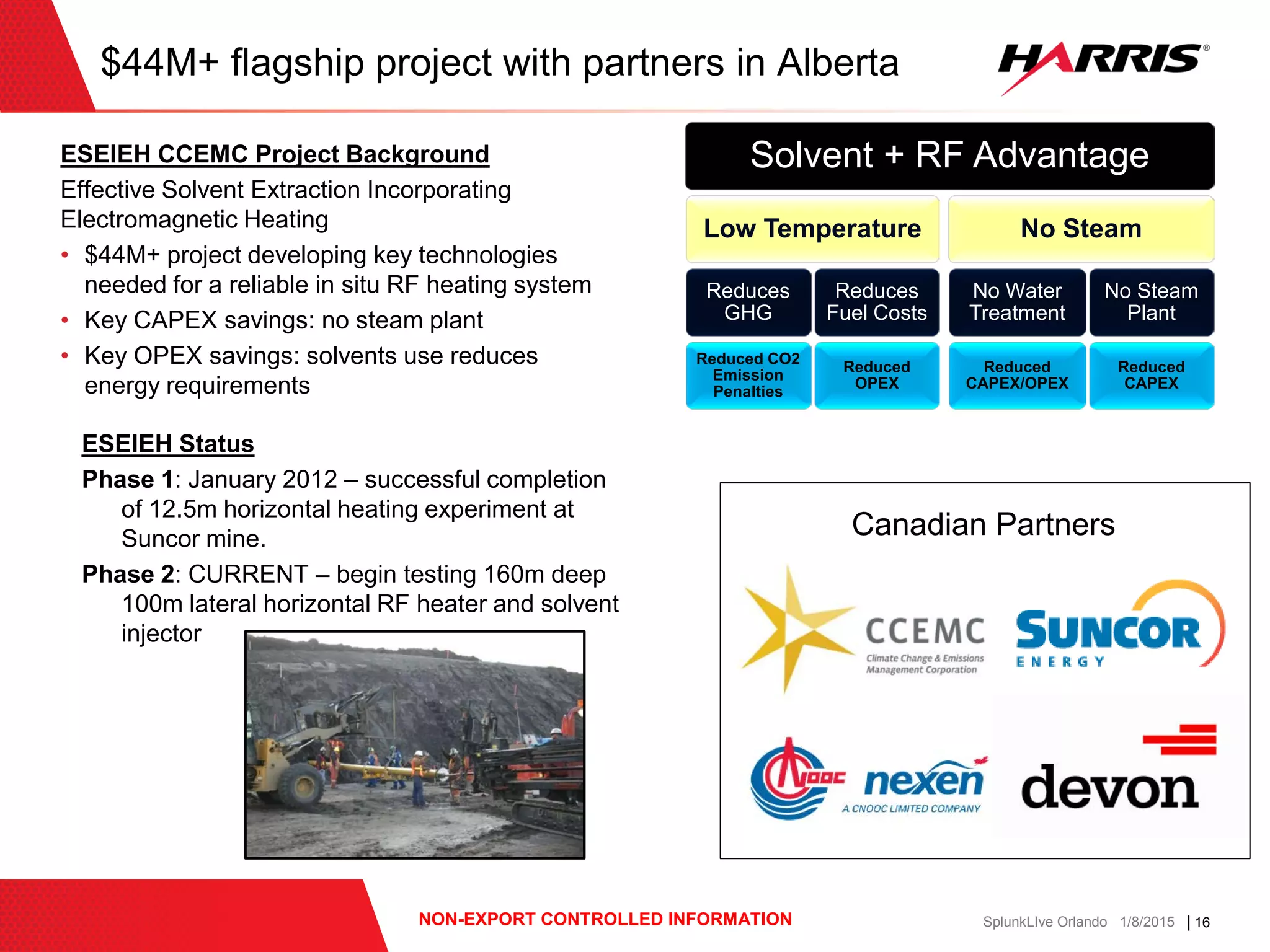

This document provides an overview of Harris Corporation's work in developing digital oilfield technologies using big data analytics. It discusses Harris' background in energy solutions and big data, how "big" oilfield data can be, and a prototype system developed by Harris to parse, store, visualize and analyze oilfield operational data using Splunk. The prototype demonstrated 3D and 5D visualization of distributed temperature sensor data across multiple wells over time. An upcoming project in Alberta, Canada will further test these digital oilfield technologies.