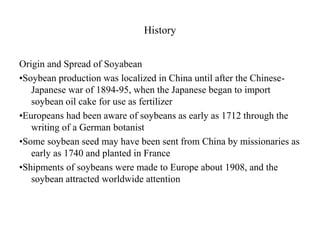

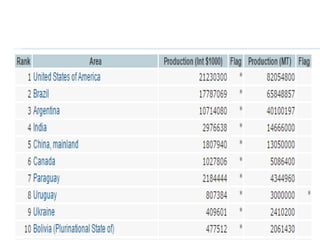

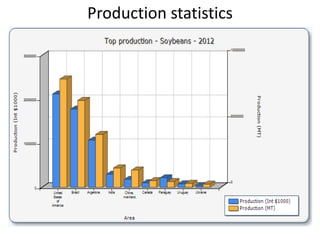

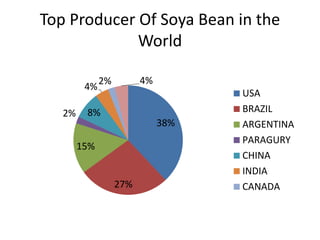

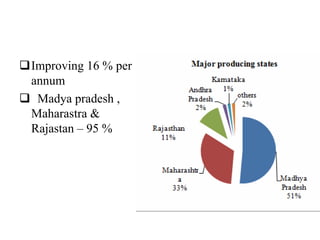

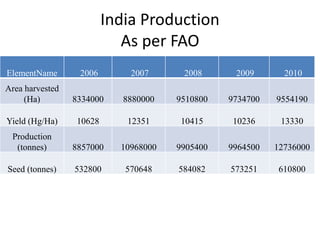

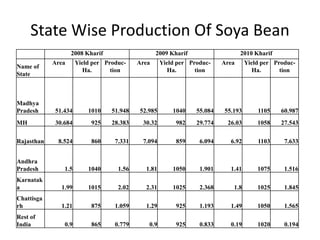

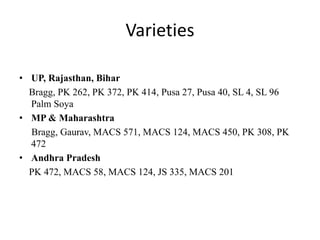

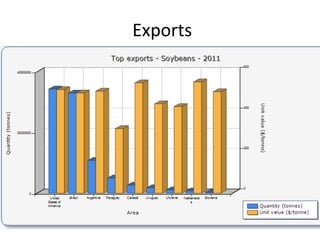

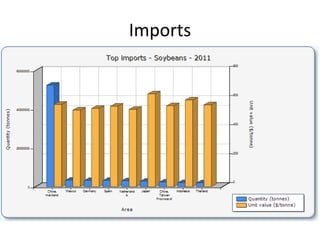

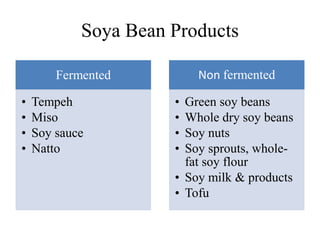

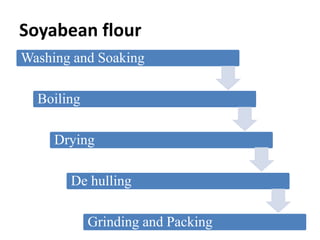

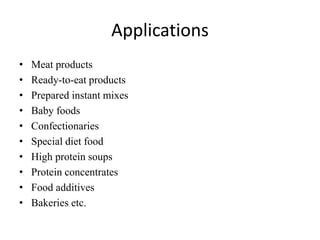

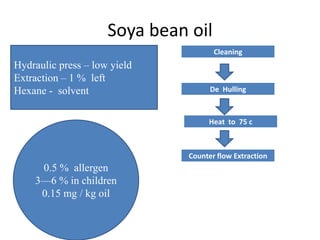

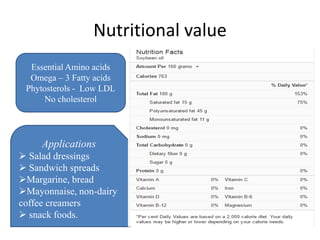

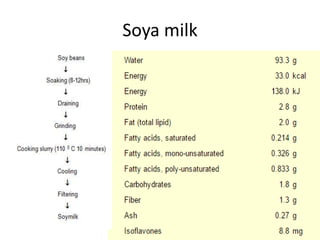

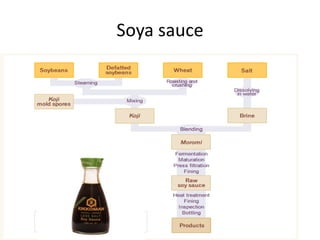

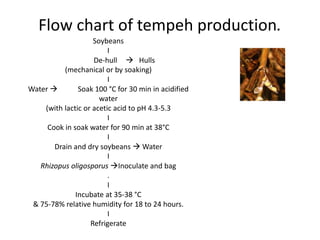

This document provides an overview of soybeans and soybean production. It discusses the origin and spread of soybeans from China to other parts of Asia and Europe. It then provides statistics on the top soybean producing countries today, with the United States, Brazil, and Argentina being the top three producers. The document also outlines India's soybean production statistics over time and the leading soybean producing states. Finally, it discusses various soybean products and their uses, including soy flour, soymilk, soy sauce, tofu and tempeh.