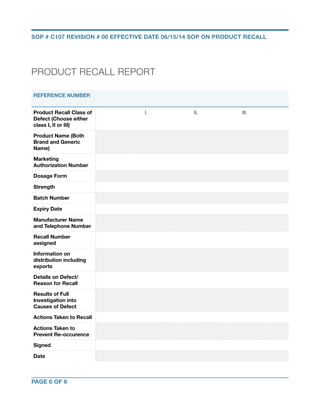

This document outlines standard operating procedures for product recalls. It defines three classes of recalls based on risk to health, with Class I being potentially life-threatening. It describes initiating a recall due to complaints, failed tests, or health risks. It also details the preliminary assessment, identifying the root cause, deciding whether to recall, notifying departments and recipients, segregating products, monitoring recall progress, reporting, and actions to prevent future issues.