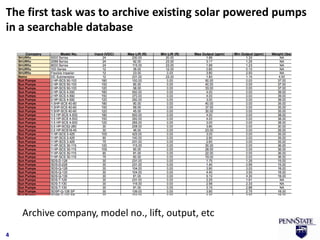

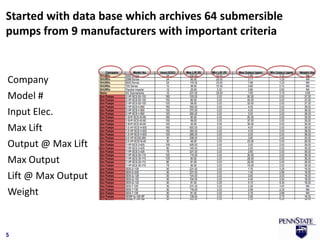

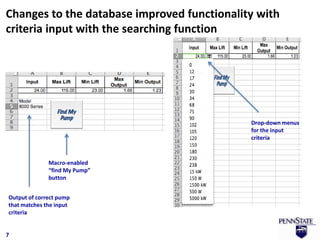

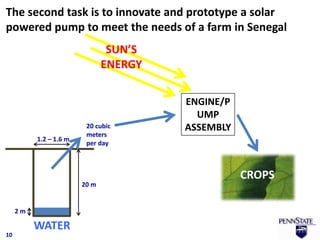

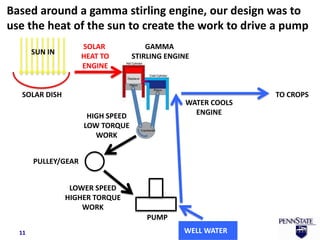

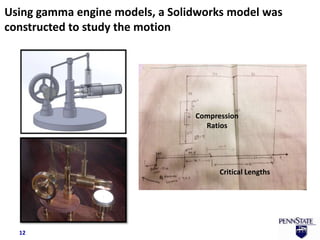

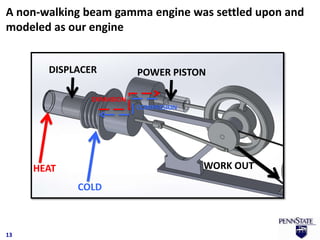

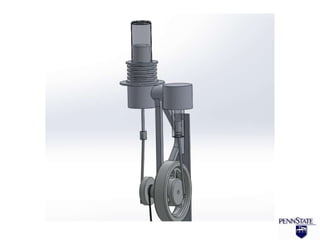

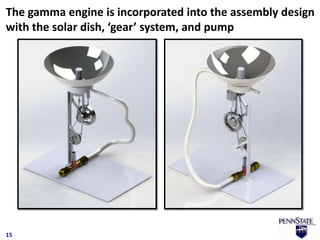

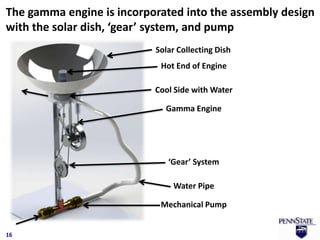

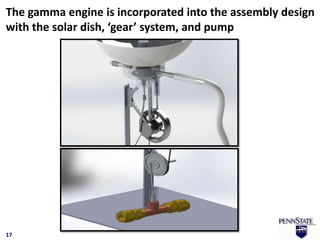

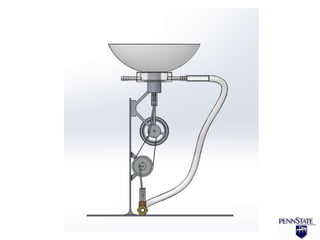

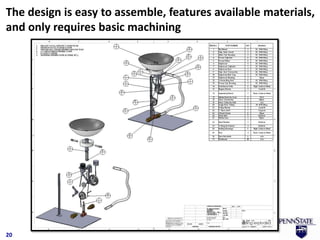

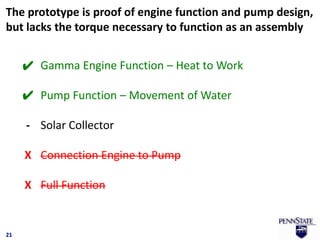

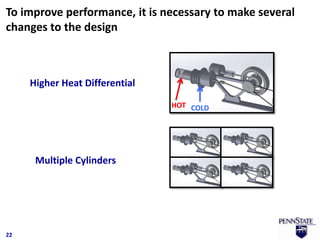

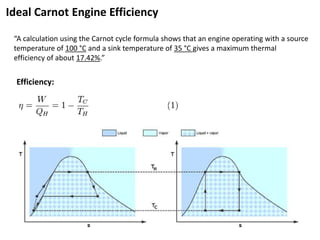

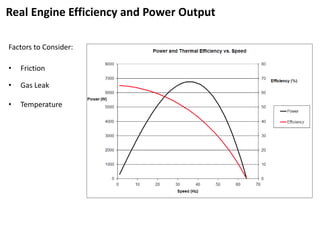

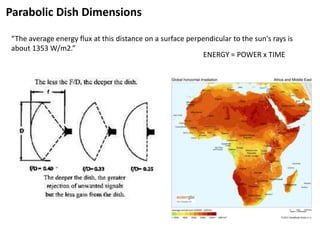

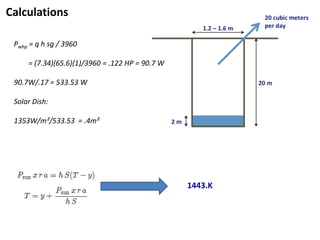

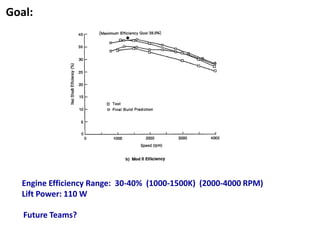

The document discusses a solar-powered water pumping project in Senegal, outlining the development of a searchable database of existing solar pumps and the innovation of a new prototype using a gamma Stirling engine. It covers project milestones, database functionalities, design considerations, and efficiency calculations for the prototype. Future steps for improvement and further design iterations are also mentioned.