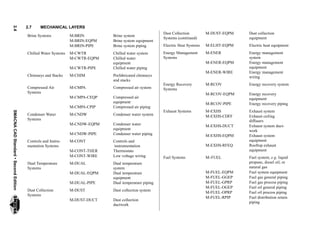

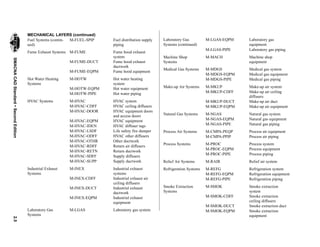

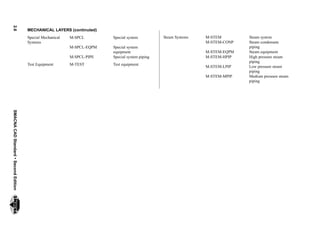

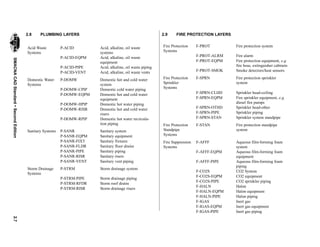

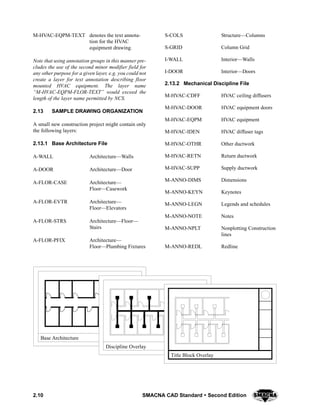

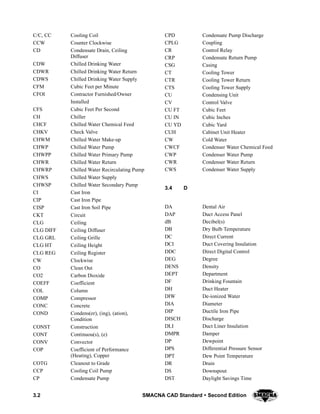

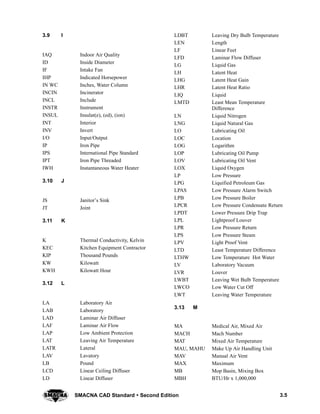

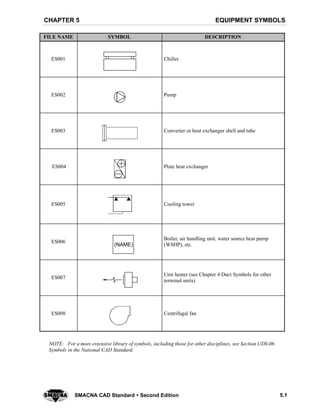

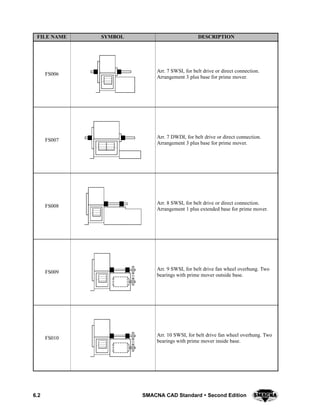

This document provides guidelines for CAD layer standards for mechanical, plumbing and fire protection drawings. It summarizes the SMACNA CAD Standard, which was developed to promote consistency in CAD layer naming and organization. The standard builds upon the National CAD Standard and provides layer naming conventions for elements from various disciplines to allow for efficient sharing and manipulation of data between design professionals using CAD software. It includes recommendations for layer structure, guidelines for layer use, and specific layer names for mechanical, plumbing and fire protection components to facilitate coordination and integration of building information.